Casting method of nodular cast iron axle box for bogie of multiple unit trains below 40 DEG C

A ductile iron and bogie technology, which is applied in the casting field of ductile iron axle boxes for bogies, can solve the problems of increasing production costs and increasing yield strength, and achieves the effects of reducing costs, reducing difficulty, and maintaining stable production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Raw material preparation

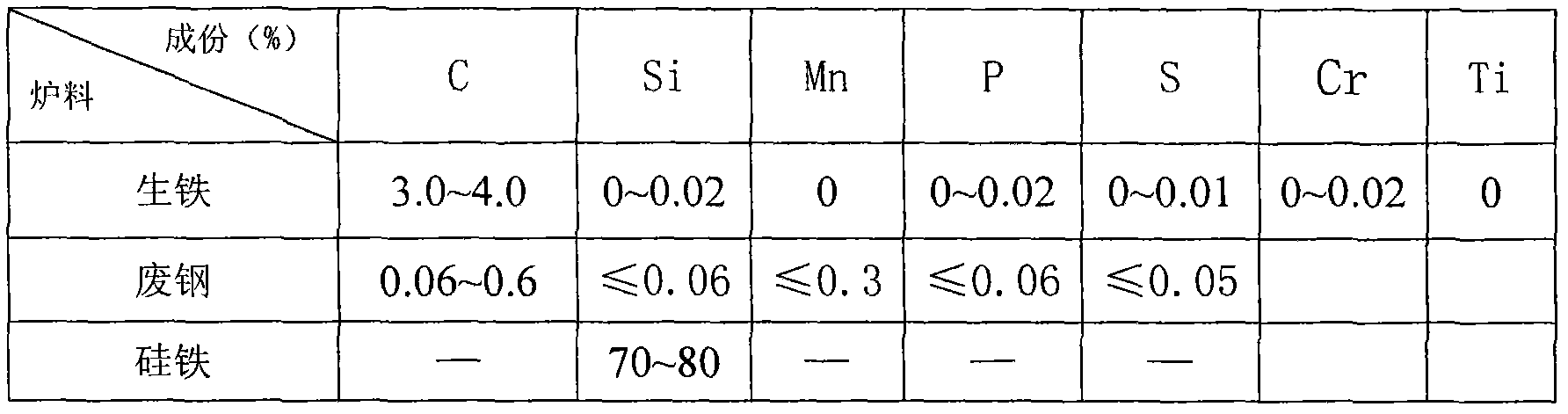

[0029] ①, pig iron, scrap steel, ferrosilicon:

[0030]

[0031] ②, Carburizer: existing commercially available materials;

[0032] ③. Nodulizer: Elkem low-magnesium and low-rare-earth nodulizer, which contains Mg: 5.5%-6.2%, Re: 0.4%-0.6%;

[0033] ④, Inoculant: Elkem low magnesium inoculant, which contains Ba: 2% ~ 3%, Ca: 1% ~ 2%, Ae Max : 1.5%.

[0034] 2. Casting grade: QT400-18LT (-40°C)

[0035] 3. The required chemical composition (mass percentage)

[0036] C: 3.6%-3.8%; Si: 1.9%-2.5%; Mn≤0.05%; P≤0.02; S≤0.05%.

[0037] 4. Mechanical properties achieved by castings

[0038] The tensile strength is above 400MPa, the yield strength is above 260MPa, the elongation is above 18%, and the average impact energy at -40°C is not less than 12J.

[0039] 5. Specific casting process:

[0040] ①, molten iron smelting

[0041] a. Melting in an intermediate frequency induction furnace;

[0042] b. Ratio of charge (%): pig iron 89%-92...

Embodiment 2

[0054] In the manufacturing process of the axle box of ductile iron for the bogie, it is generally carried out in batches with multiple furnaces, that is, the continuous production of several furnace products. In order to improve the utilization rate of production costs, the casting process of the present invention can effectively reduce production costs by utilizing returned materials, which is embodied in the preparation of raw materials, namely:

[0055] 1. 55%-60% of pig iron, 38%-42% of recycled material, 9%-12% of steel scrap, 0.3%-0.4% of ferrosilicon:

[0056] 2. Nodulizer: Elkem low magnesium and low rare earth nodulizer, containing Mg: 5.5%~6.2%, Re: 0.4%~0.6%;

[0057] 3. Inoculant: Elkem low magnesium inoculant, containing Ba: 2%~3%, Ca: 1%~2%, Ae Max : 1.5%.

[0058] It is obvious that compared with Example 1, not only the ratio of pig iron, a high-cost raw material, can be greatly reduced, but also the use of recarburizer will no longer be required.

[0059] E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com