High-speed precise electric spindle cooling system

A cooling system and motorized spindle technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of not being able to cool and lubricate bearings, increase bearing preload, and aggravate bearing heating, etc. The effect of machining accuracy error, improving service life and ensuring temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

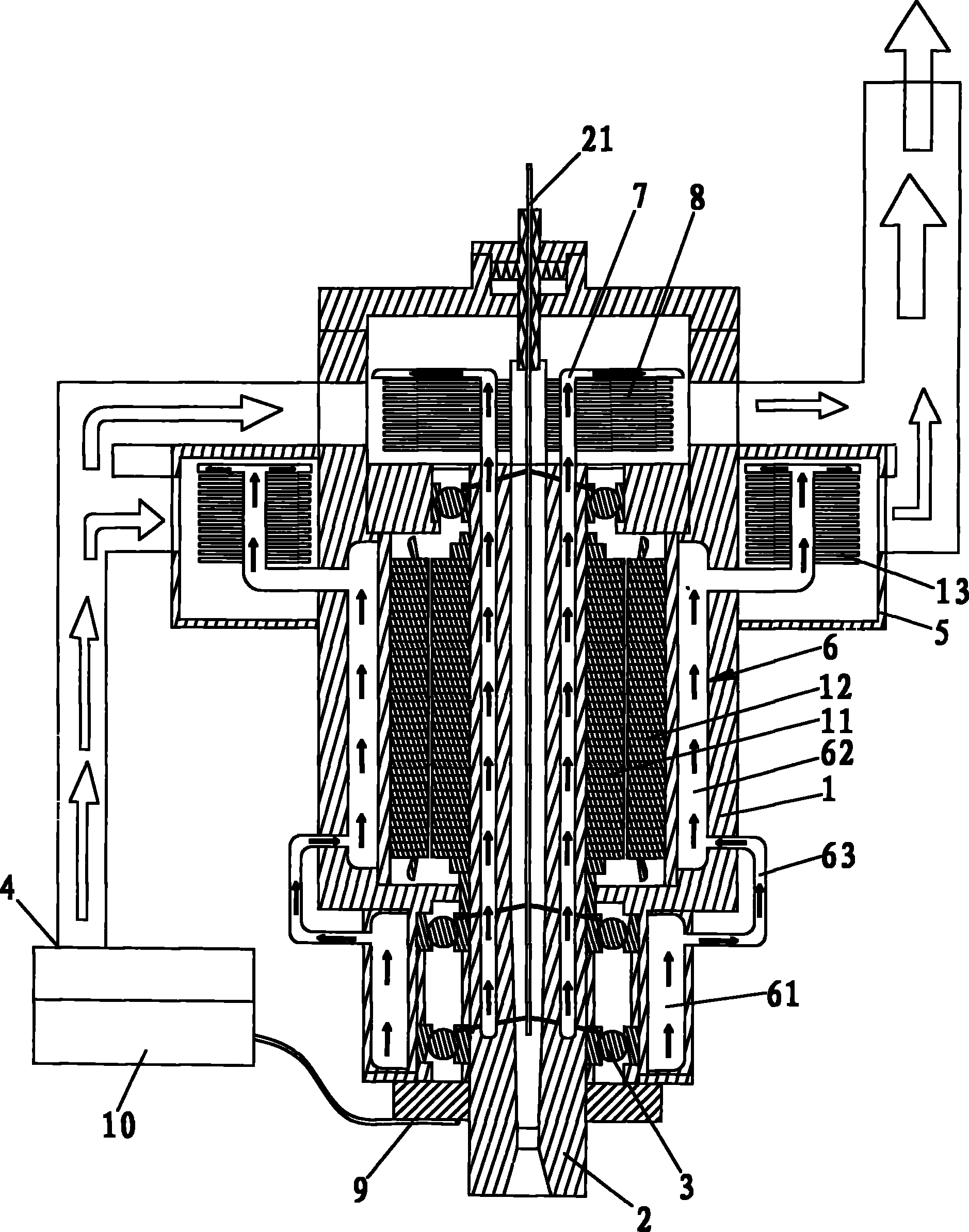

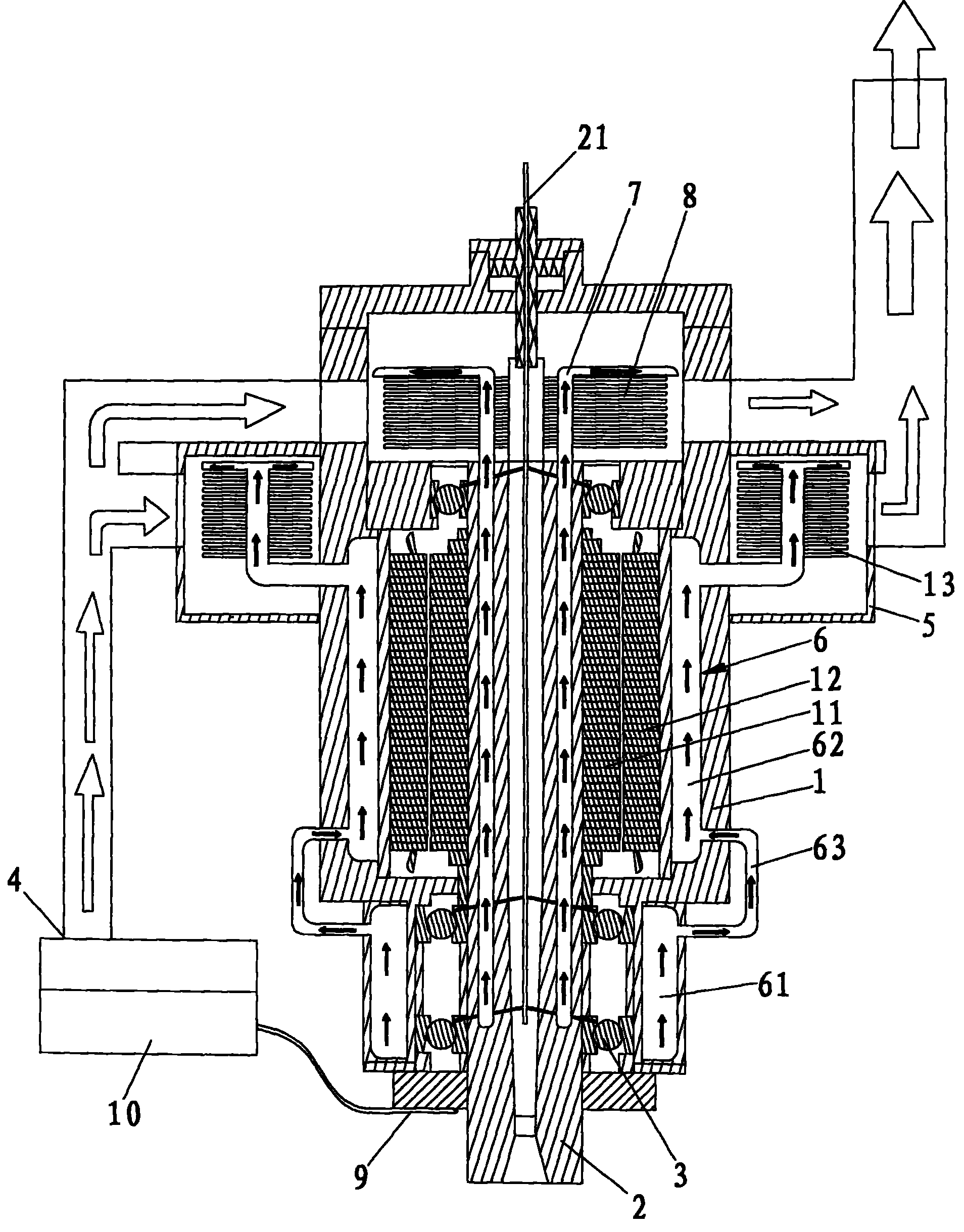

[0015] Below in conjunction with accompanying drawing, the present invention will be further described, see figure 1 As shown, the high-speed precision electric spindle cooling system of the present invention includes an electric spindle housing 1, an electric spindle core 2, a rotor 11, a stator 12, and a cooling air conditioner 4, and the two ends of the electric spindle core 2 are rotatably connected by bearings 3 In the motorized spindle housing 1, the rotor 11 is sleeved on the motorized spindle shaft core 2, the stator 12 is fixed inside the motorized spindle housing 1, the rear end of the motorized spindle housing 1 is provided with an annular cooling seal cover 5, and the annular cooling seal The cover 5 communicates with the cooling gas output port of the cooling air conditioner 4. The electric spindle housing 1 is provided with a housing heat pipe 6. The evaporation end of the housing heat pipe 6 extends to the front bearing 3, and the condensation end of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com