Packaging waste polymer/nano coextrusion modified asphalt and preparation method thereof

A technology of modified asphalt and polymers, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of limited improvement range, ineffective improvement of asphalt performance, and high cost of modified asphalt, so as to improve the comprehensive Performance, mitigation of white pollution, and reduction of modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

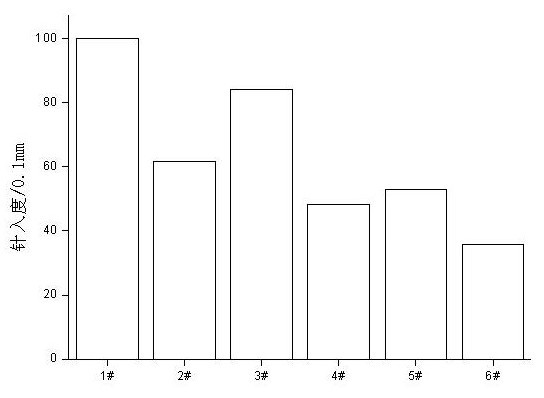

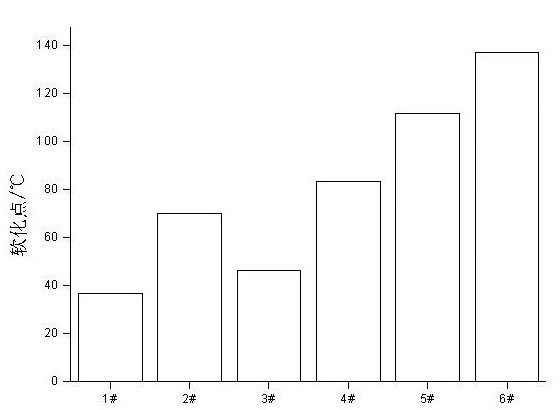

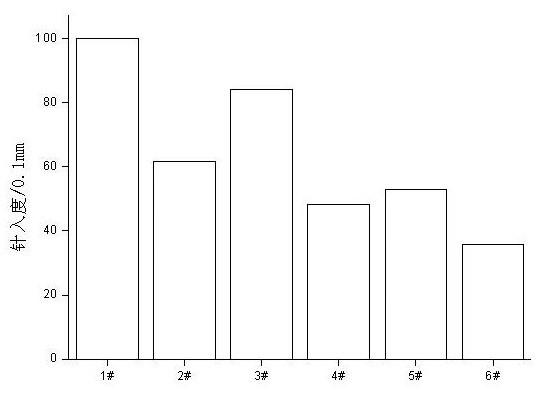

Embodiment 1

[0045] Melt and co-extrude 0.5% packaging waste polymer PE and 0.5% nano-montmorillonite on an extruder to prepare a modifier by mass percentage, take 99% mass percentage of base asphalt to heat and melt, keep the temperature at 150 ° C, add Modifier, manual stirring for 20 minutes, shearing machine stirring for 80 minutes, cooling to 150°C, standing for 50 minutes to make it fully swell; shearing the mixture again on the shearing machine for 80 minutes, until packaging waste polymer PE and nano-montmorillonite Soil melt co-extrusion modifier uniformly dispersed in asphalt, that is. After testing, the penetration of the modified asphalt is 78.8 (0.1mm), and the softening point is 50.4°C.

Embodiment 2

[0047] Melt and co-extrude 13% of packaging waste polymer PE and 12% of nano-montmorillonite on the extruder according to the mass percentage to prepare the modifier; take 75% of the mass percentage of the base asphalt to heat and melt, keep the temperature at 180 ° C, add The prepared modifier was manually stirred for 30 minutes, then stirred by a shear for 80 minutes, cooled to 120°C, and placed for 30 minutes to make it fully swell; the mixture was sheared again on a shear for 90 minutes until the waste polymer PE and The melt co-extrusion modifier of nanometer montmorillonite is evenly dispersed in asphalt. After testing, the penetration of the modified asphalt is 35.4 (0.1mm), and the softening point is 137.2°C.

Embodiment 3

[0049] According to the mass percentage, 10.9% of packaging waste polymer PE and 0.1% of nano-montmorillonite were melted and co-extruded on an extruder to prepare the modifier. Take 89% of the base asphalt by mass and heat it to melt, keep the temperature at 200°C, add the prepared modifier, stir manually for 40 minutes, stir with a shear for 100 minutes, cool down to 100°C, and let it stand for 20 minutes to fully swell; The material is sheared again on a shearing machine for 100 minutes until the melt co-extrusion modifier of packaging waste polymer PE and nano-montmorillonite is uniformly dispersed in the asphalt, and the product is obtained. After testing, the penetration of the modified asphalt is 38.7 (0.1mm), and the softening point is 107.9°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com