Preparation method of ultra-dispersed nano white carbon black for rubber filler

A nano-silica, rubber filler technology, applied in fibrous fillers, chemical instruments and methods, inorganic pigment treatment and other directions, can solve problems such as easy agglomeration, achieve less environmental pollution, improve compatibility, and reduce modification costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

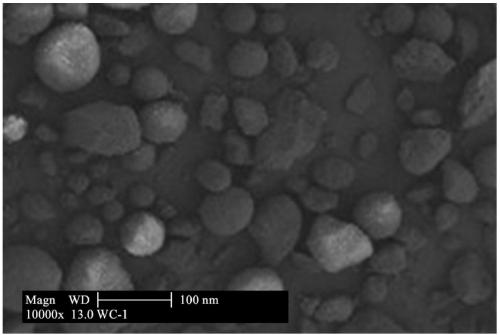

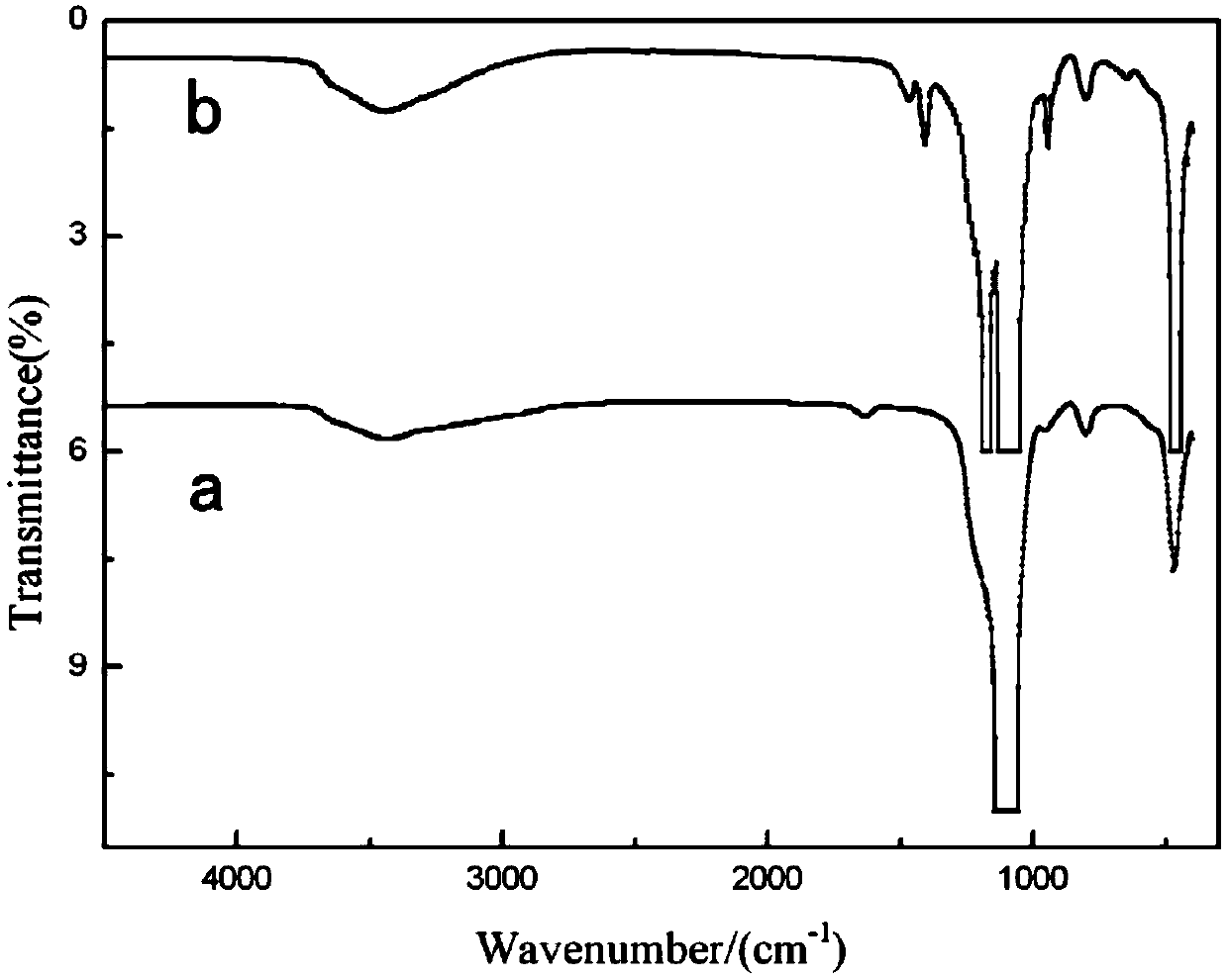

[0047] (1) Preparation of silicone / alkylphenol polyoxyethylene ether copolymer: first add 100 parts of KH-550 and 100 parts of cyclohexane into the reactor, stir for 1.0 hr, then add 5.0 parts of NPEO, continue stirring and heating When the temperature of the reactor reaches 50°C, quickly add 0.5 parts of sodium hydroxide under stirring conditions, react for 5.0 hours, reduce pressure and distill to obtain KH-550 / NPEO copolymer a.

[0048] (2) Preparation of acylated solution-polymerized styrene-butadiene mortar: first add 100 parts of solution-polymerized styrene-butadiene mortar SSBR2564s and 100 parts of CS in the polymerization kettle 2 , stirring and heating, when the temperature of the polymerization tank reaches 40°C, quickly add 0.09 parts of AlCl under stirring conditions 3 , add 5 parts of MAH until the system becomes orange-red, stir and react for 2hr, add 5 parts of formex to terminate the reaction, filter with suction and wash to obtain acylated soluble polystyren...

Embodiment 2

[0051] (1) Preparation of organosilicon / alkylphenol polyoxyethylene ether copolymer: same as Example 1.

[0052] (2) Preparation of acylated solution-polymerized styrene-butadiene mortar: same as Example 1.

[0053] (3) Preparation of ultra-dispersed nano-silica: Take 100 parts of nano-silica (40nm), 6 parts of KH-550 / NPEO copolymer a, and 230 parts of cyclohexane into the polymerization kettle, and heat up to 45°C , stirring and reacting for 1.5hr; then adding 14 parts of acylated styrene-butadiene mortar a, stirring and reacting for 2.5hr, and then flashing, drying and grinding to obtain super-dispersed nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 3

[0055] (1) Preparation of organosilicon / alkylphenol polyoxyethylene ether copolymer: same as Example 1.

[0056] (2) Preparation of acylated solution-polymerized styrene-butadiene mortar: same as Example 1.

[0057](3) Preparation of ultra-dispersed nano-silica: Take 100 parts of nano-silica (40nm), 8 parts of KH-550 / NPEO copolymer a, and 280 parts of cyclohexane into the polymerization kettle, and heat up to 45°C , stirring and reacting for 1.9hr; then adding 19 parts of acylated styrene-butadiene mortar a, stirring and reacting for 2.8hr, and then flashing, drying and grinding to obtain super-dispersed nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com