Formula and preparation method of modified green twill stitched non-woven fabric

A modification and twill weave technology, which is applied in non-woven fabrics, stretch spinning, rayon manufacturing, etc., can solve the problems of high cost, low bulk density, and difficulty in recycling, so as to reduce modification costs and additives The effect of adding and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

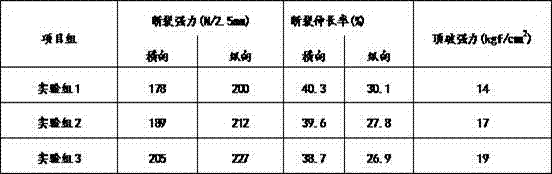

Examples

Embodiment 1

[0027] The invention discloses a formula of modified green twill core cloth, including modified green polyester, low melting point cotton, three-dimensional vacuum cotton and polyester filament, modified green polyester, low melting point cotton, three-dimensional vacuum cotton and polyester filament The mass fractions are: low melting point cotton 8-22%, modified green polyester 42-58%, three-dimensional vacuum cotton 9-11%; polyester filament 20-27%.

[0028] Wherein, the preparation steps of modified green polyester are as follows:

[0029] S1. Polyester recycled materials are soaked in hydrogen peroxide with a concentration of 10-25% after collection, and the soaking time is 5-10 minutes; the surface oxidized polyester recycled materials are placed in a vacuum drum drying equipment for drying, and the drying time is 8-10 hours;

[0030] S2. Take 100g surface oxidized recycled polyester material, add 5-8g chitosan and 1-5g glass fiber to polymerize and increase viscosity, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com