Solid detergent wrapped by water-soluble film

A detergent and water-soluble film technology, applied in the field of daily chemicals, can solve the problems of increasing product cost and material consumption, high requirements for equipment and production energy consumption, and increasing the difficulty of product dissolution, so as to avoid the difficulty of dissolution and reduce the cost of materials Effect of consumption and improvement of greenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to specific embodiments.

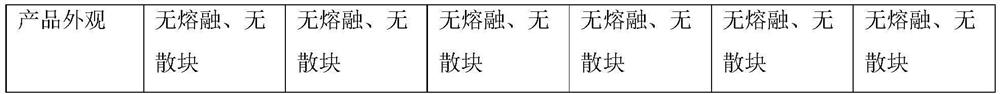

[0022] The components of the solid detergent wrapped in the water-soluble film described in Examples 1-6 are shown in Table 1:

[0023] Table 1

[0024]

[0025] The solid detergent wrapped in the water-soluble film described in the above embodiment is prepared by the following steps:

[0026] A) Mix the nonionic surfactant in molten state with corn starch uniformly, then add anionic surfactant and sodium bentonite of 1 / 2 dosage and mix uniformly to obtain mixture A;

[0027] B) Mix the macromolecular auxiliaries, the remaining washing auxiliaries and other components evenly to obtain mixture B; if the macromolecular auxiliaries contain liquid raw materials, it is necessary to ensure that the liquid macromolecular auxiliaries are added when they are in a molten state;

[0028] C) adding mixture A to mixture B to obtain mixture C;

[0029] D) compressing the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com