Lead powder electrochemical performance detection method based on small polar plate and test system therefor

A detection method and technology of a test system, applied in the field of electrochemistry, can solve the problems of poor stability of electrochemical test results, inability to explore the influence of battery lead paste performance, etc., to shorten the test cycle, improve the test efficiency, and shorten the process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

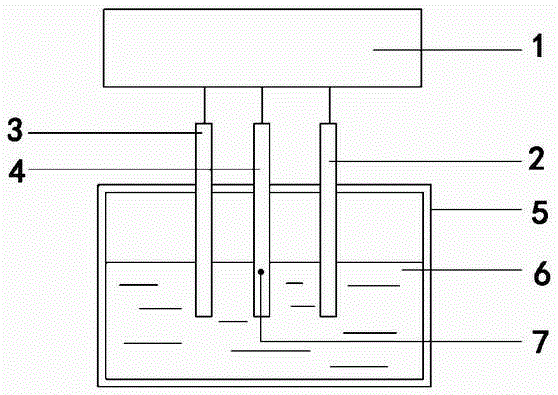

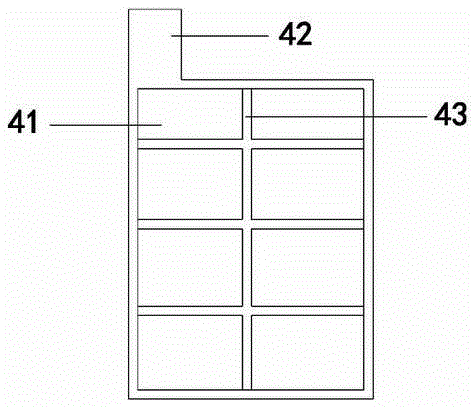

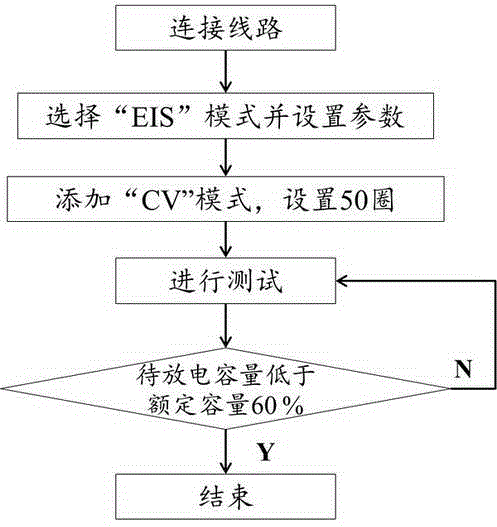

[0021] figure 1 Among them, the present invention includes a counter electrode 2, a reference electrode 3, a working electrode 4, and an electrolytic cell 5. The electrolytic cell 5 is filled with electrolyte 6, and one end of the counter electrode 2, the reference electrode 3 and the working electrode 4 are inserted into the electrolytic cell. 5. The working electrode 4 is filled with an active material 7, which is the object to be tested, such as a lead paste active material prepared from lead powder to be evaluated. The counter electrode 2 adopts a single or double inert electrode (such as platinum electrode, gold electrode), and its surface area is smaller than that of the working electrode. The reference electrode 3 uses a mercury sulfate electrode. The detection cell is a sealable special three-necked flask or electrolytic cell for electrochemical detection. The three electrodes are placed in the electrolytic cell 5, and their spacing is fixed by the hole pitch of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com