Method and device for preparing modified sponge with high amino content, and algae removal application

A technology of modified sponge and high amine group, applied in chemical instruments and methods, alkali metal oxides/hydroxides, special treatment targets, etc., to achieve the effects of low modification cost, easy regeneration and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

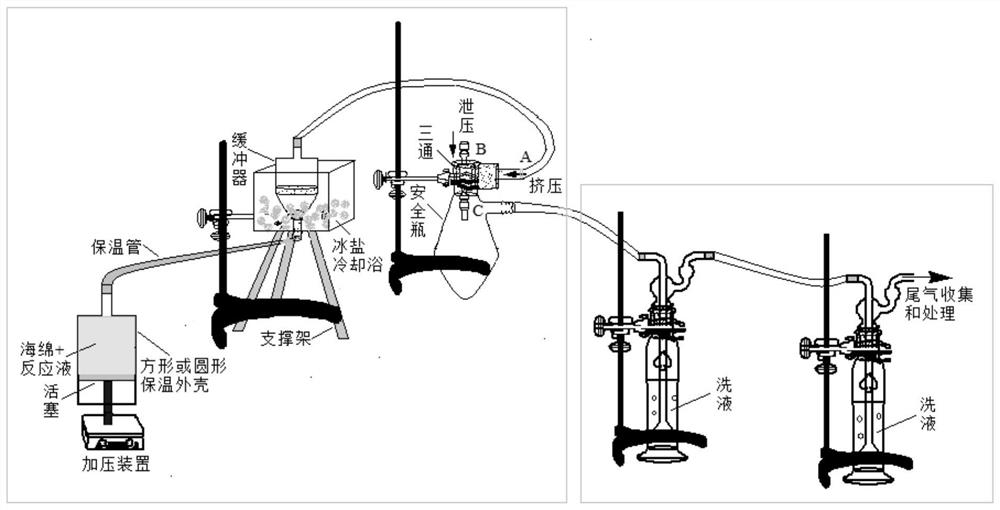

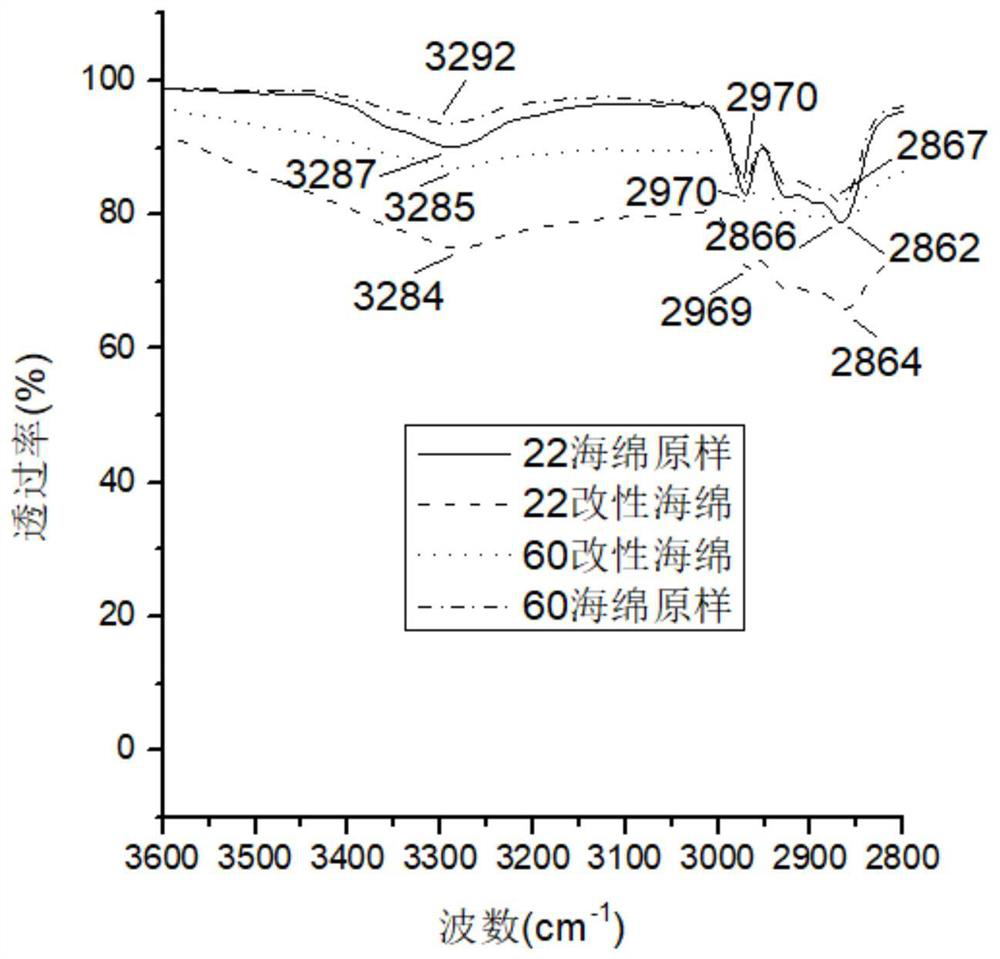

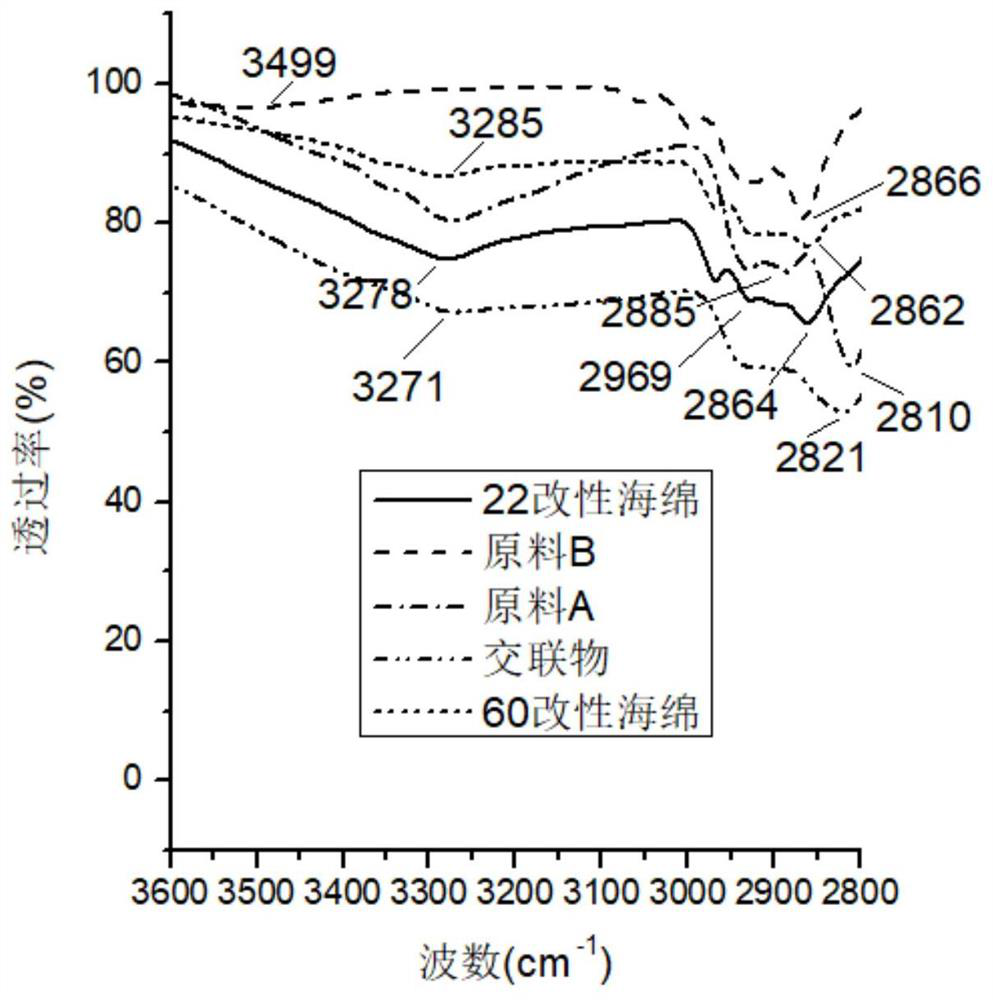

[0068] The preparation method of the aminated low-density modified sponge specifically comprises the following preparation steps:

[0069] (1) Feeding in the wet extrusion device

[0070] The polyethyleneimine (ethanol: water = 1) solution with a molecular weight of 20000 is the raw material A reaction solution, the weight concentration is 0.1g / mL, and the concentration of imine chains is 2.33mmol / mL. The ethanol solution of 1,4-butanediol diglycidyl ether is the raw material B reaction solution, the weight concentration is 0.157g / mL, and the epoxy concentration is 1.16mmol / mL based on the epoxy number of 0.74. The number of imine chains / epoxy number is 10:1, take corresponding volumes of A reaction solution and B reaction solution, mix and stir evenly under ice-salt bath cooling. A pre-cooled PU sponge with a size of 2 x 2 x 2 cm and a density of 22 mg / mL was put into the wetting squeeze device from the sponge inlet. The reaction mixture is added to the wetting device from ...

Embodiment 2

[0081] The difference between this example and Example 1 is that the size of the sponge is 10×10×2 cm, the density is 22 mg / mL, the extrusion rate of the sponge is 87.5%, the cross-linking time is 120 min, and the washing extrusion rate is 25%.

Embodiment 3

[0083] The difference between this example and Example 1 is that the size of the sponge is 2×2×2 cm, the density is 60 mg / mL, the extrusion rate of the sponge is 65%, the crosslinking time is 110 min; the washing extrusion rate is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com