Solid waste phosphogypsum compound modified asphalt and preparation method thereof

A technology for compound modified asphalt and solid waste, which is applied in building structures, building components, building insulation materials, etc., can solve problems such as land occupation and environmental pollution, reduce raw material costs, simplify the process, and reduce environmental pollution. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing solid waste phosphogypsum composite modified asphalt, comprising the following raw material components in weight ratio: 80%-90% of petroleum heavy traffic asphalt, 3%-5% of phosphogypsum, 1%-3% of polyphosphoric acid, rubber Powder 3%-8%, polymer 2%-4%, coupling agent 0.5%-1%, and cross-linking agent 0.5%-1%;

[0020] Wherein said phosphogypsum adopts the waste slag phosphogypsum produced in the production process of wet-process phosphoric acid, and is a dried gypsum product after being calcined to remove moisture; Phosphoric acid products; the rubber powder refers to the powder obtained by crushing waste rubber products; the high molecular polymer is one or more of styrene-butadiene thermoplastic rubber, thermoplastic polyurethane rubber, rosin resin and petroleum resin a mixture; the coupling agent is one of aluminate, silane, and titanate; the crosslinking agent is sulfur, or a mixture of sulfur and maleic anhydride.

[0021] The specific prod...

Embodiment example 1

[0026] First prepare the following raw material components by weight: 84.5% petroleum heavy traffic asphalt, 5% phosphogypsum, 1% polyphosphoric acid, 4.5% rubber powder, 4% polymer, 0.5% coupling agent and 0.5% crosslinking agent ;

[0027] Prepare composite modified asphalt according to the following steps:

[0028] a. Heat petroleum heavy traffic asphalt to 190°C, put phosphogypsum and high molecular polymer into it after it melts, and stir for 2 hours with a shearing mixing head;

[0029] b. Under the condition of 150°C, put rubber powder into the material treated in step a) and stir for 1 hour;

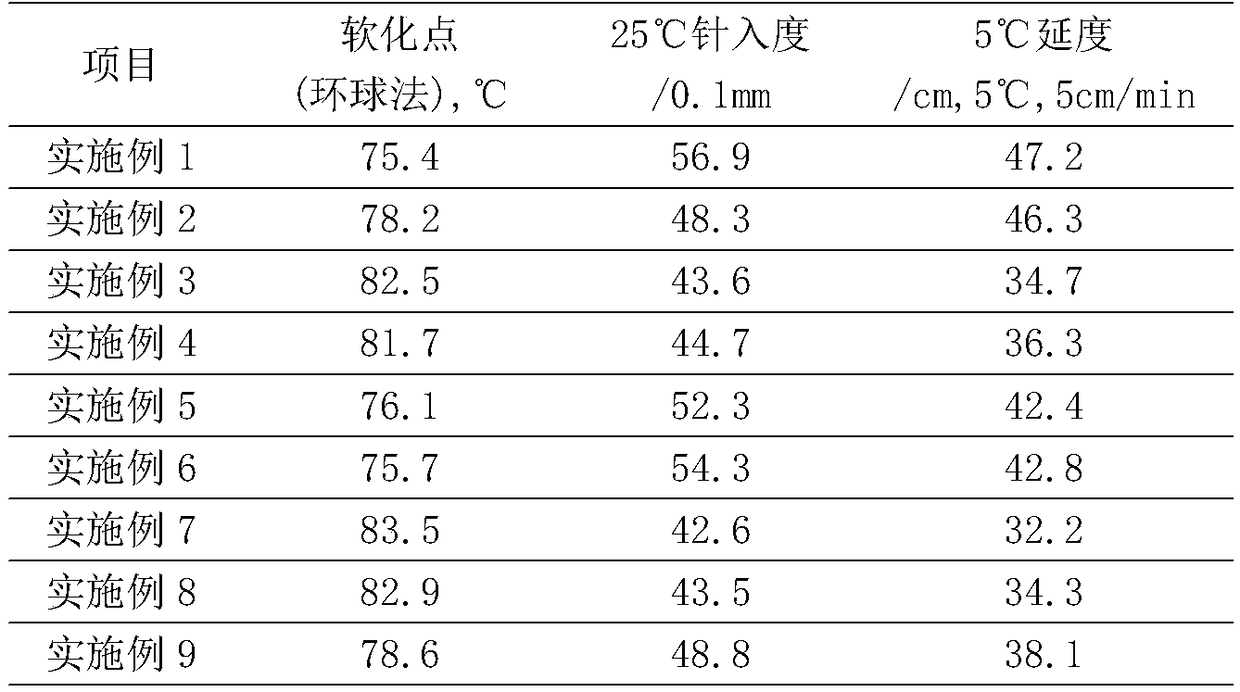

[0030] c. Under the condition of 130°C, add polyphosphoric acid, coupling agent and crosslinking agent to the material treated in step b) and stir for 5 hours to obtain the composite modified asphalt sample 1, the sample 1 See Table 1 for technical indicators.

Embodiment example 2

[0032] First prepare the following raw material components by weight: 82% petroleum heavy traffic asphalt, 5% phosphogypsum, 2% polyphosphoric acid, 5% rubber powder, 4% polymer, 1% coupling agent and 1% crosslinking agent ;

[0033] Prepare composite modified asphalt according to the following steps:

[0034] a. Heat petroleum heavy traffic asphalt to 190°C, put phosphogypsum and high molecular polymer into it after it melts, and stir for 2 hours with a shearing mixing head;

[0035] b. Under the condition of 150°C, put rubber powder into the material treated in step a) and stir for 2 hours;

[0036] c. Under the condition of 140°C, add polyphosphoric acid, coupling agent and crosslinking agent to the material treated in step b) and stir for 6 hours to obtain the composite modified asphalt sample 2, the sample 2 See Table 1 for technical indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com