Elastic fuzz polyurethane paint

A polyurethane coating and fluff technology, applied in the direction of polyurea/polyurethane coating, coating, etc., to achieve the effect of good construction tolerance, good water resistance, and improved coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

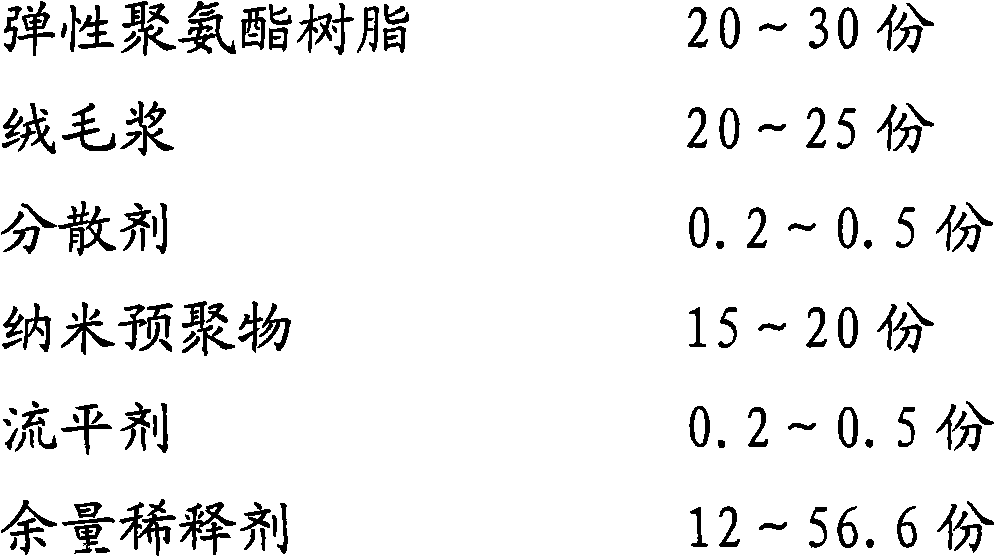

Method used

Image

Examples

Embodiment 1

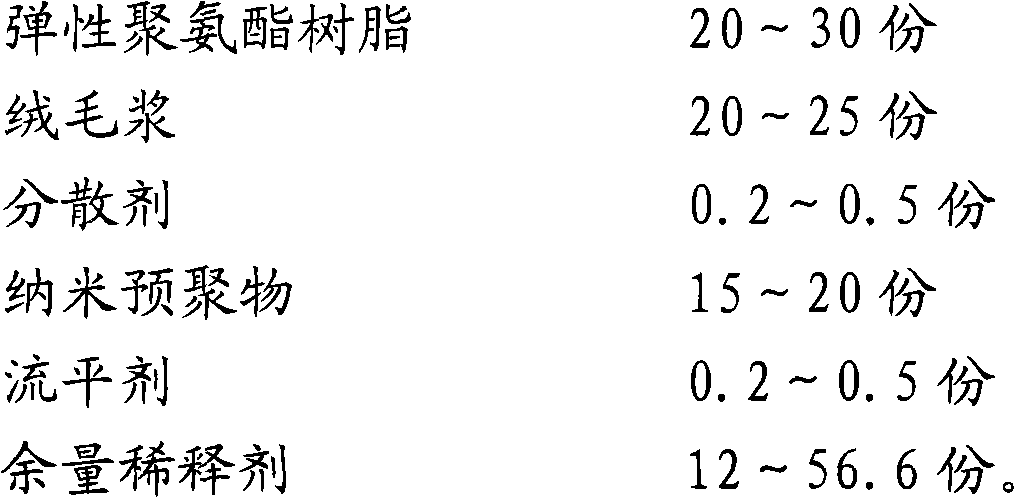

[0026] Component A: 20 parts by weight of elastic polyurethane resin Japan Tiancheng CM-6089, 25 parts of fluff pulp (by weight proportion: fluff powder: hand feeling agent: solvent = 8: 0.9: 4) dispersant German Qian 9100.2 parts, under stirring, add 15 parts of nano-prepolymer (the proportion by weight is mica powder: nano-montmorillonite: dispersant: solvent = 45: 18: 0.1: 36.9); grind to fineness ≤ 30 μm; put 0.2 part of leveling agent BYK306 in Germany, and 39.6 parts of remaining diluent (distribution ratio by weight: butyl acetate: propylene glycol methyl ether acetate = 3:7); after passing the inspection, it can be made into a group. points A;

[0027] Component B: 30 parts of HDI trimer polyisocyanate, 40 parts of HDI-TDI trimer, and 30 parts of butyl acetate by weight ratio are mixed evenly, and then component B can be prepared;

[0028] Component C: 70 parts of butyl acetate and 30 parts of propylene glycol methyl ether acetate are mixed evenly by weight, and then ...

Embodiment 2

[0031] Component A: 25 parts of elastic polyurethane resin Japan Tiancheng TM-6080 and 20 parts of fluff pulp (in proportion by weight: fluff powder: hand feeling agent: solvent = 10: 0.6: 6) are put into the dispersing cylinder Add 0.3 part of dispersant Deqian 903, and under stirring, add 17 parts of nano-prepolymer (the proportion by weight is mica powder: nano-montmorillonite: dispersant: solvent = 50: 15: 0.1: 34.9) , dispersed for 10min; ground to a fineness of ≤30 μm; put into leveling agent BYK358N 0.3 part, the remaining diluent (by weight distribution ratio: butyl acetate: propylene glycol methyl ether acetate = 5: 10) 37.4 parts ; After passing the inspection, it can be made into component A;

[0032] Component B: 40 parts of HDI trimer polyisocyanate, 30 parts of HDI-TDI trimer, and 30 parts of butyl acetate by weight ratio are mixed evenly, and then component B can be prepared;

[0033] Component C: by weight, 80 parts of butyl acetate and 20 parts of propylene g...

Embodiment 3

[0036] Component A: 30 parts of elastic polyurethane resin Japan Tiancheng M1783 and 25 parts of fluff pulp (in proportion by weight: fluff powder: hand feeling agent: solvent=10: 0.7: 6) are put into the dispersing cylinder in proportion by weight, Add 0.5 part of dispersant Huaxia HX-4030, under stirring, add 20 parts of nano-prepolymer (the proportion by weight is mica powder: nano-montmorillonite: dispersant: solvent=60: 18: 0.2: 21.8), Disperse for 30min; grind to a fineness of ≤30μm; put in 0.5 part of leveling agent Deqian 435 and the remaining amount of diluent (distribution ratio by weight: butyl acetate: propylene glycol methyl ether acetate = 15:5) 24 parts; inspection After qualified, it can be made into component A;

[0037] Component B: 35 parts of HDI trimer polyisocyanate, 35 parts of HDI-TDI trimer, and 30 parts of butyl acetate by weight ratio are mixed evenly, and then component B can be prepared;

[0038] Component C: 90 parts by weight of butyl acetate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com