Cathode boss structure of aluminum electrolysis cell

A boss structure, aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problems of reduced electrochemical reaction efficiency, increased noise value of electrolytic cell, unstable electrolyte system, etc., to reduce electrochemical corrosion and reduce aluminum production. , the effect of reducing the backlog of funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

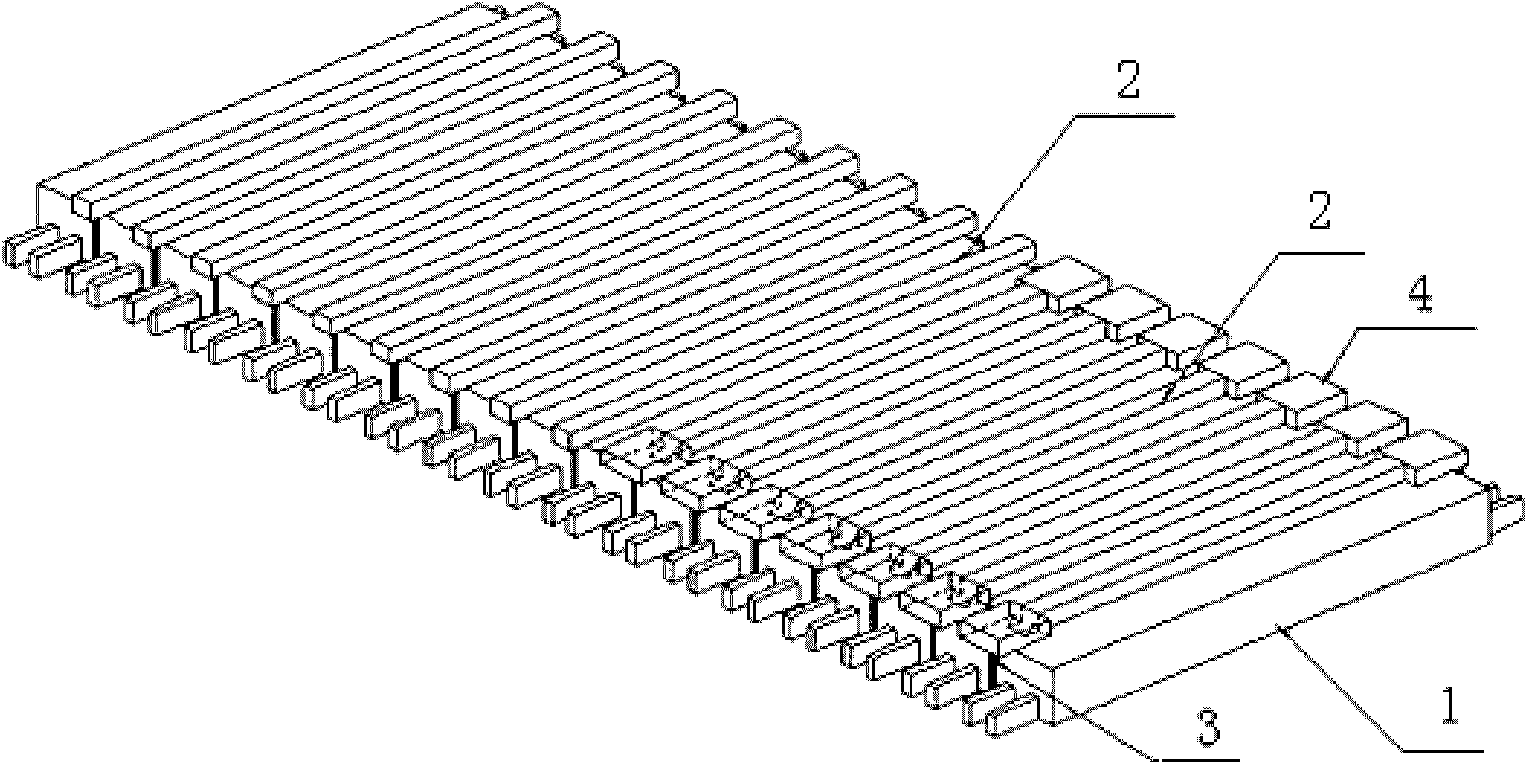

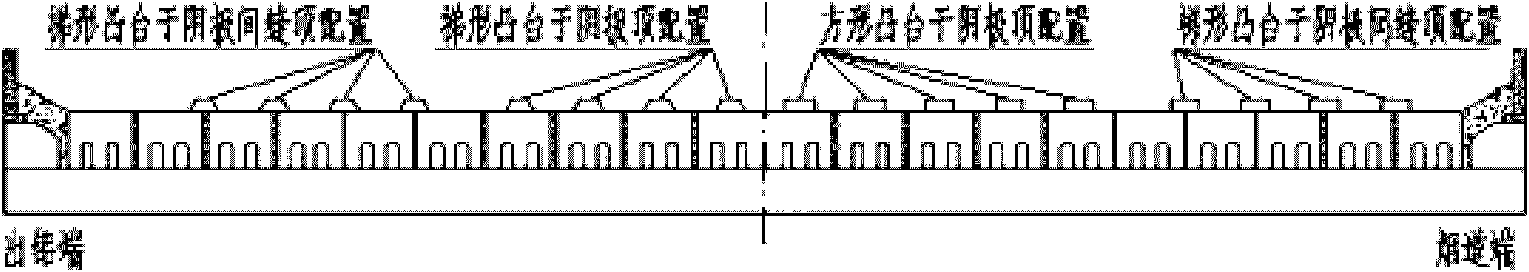

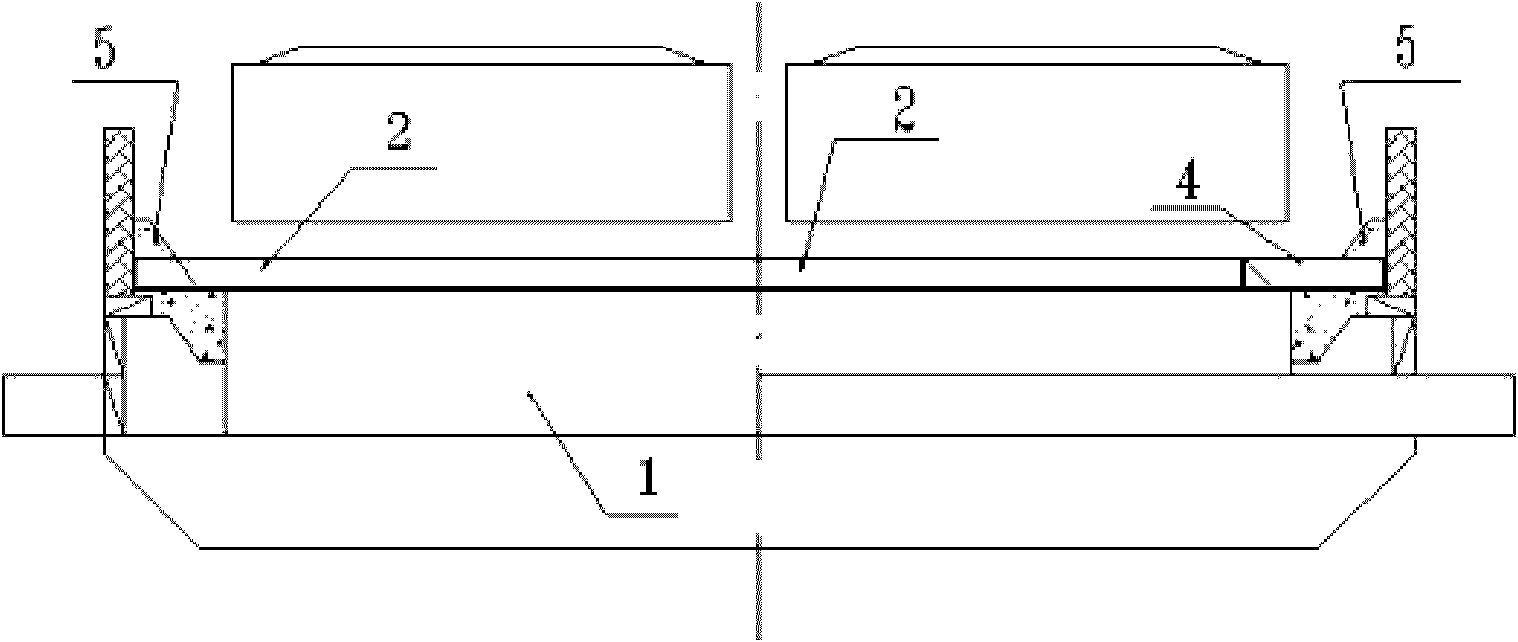

[0024] Embodiments of the present invention: as figure 1 , 2 , 3, it mainly includes: cathode carbon block 1, cathode boss 2, restraint carbon block 4, cathode boss 2 is placed on the top surface of the cathode carbon block 1 of the electrolytic cell, or placed on the cathode gap 3, The distance between the cathode bosses is in the range of 400mm to 900mm, and it can be arranged sparsely or densely according to different groove types.

[0025] There are two ways to implant the cathode boss 2 . Method 1: The cathode boss with a long structure is 100-250mm longer than the cathode carbon block, and the two ends are directly embedded in the paste 5 around the side; Method 2: The cathode boss of the mosaic butt joint type has a length of Within the range of 3000-3200mm, the two ends are respectively fixed with constrained carbon blocks 4, and the constrained carbon blocks are embedded in the paste 5 around the side.

[0026] The cross-section of the cathode boss 2 is a rectangl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com