Diffusion absorption type thermal converter without moving parts

A heat exchanger and absorption technology, applied in the field of diffusion absorption heat exchangers, can solve problems such as limiting wide application, and achieve the effect of improving reliability and solving corrosion problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

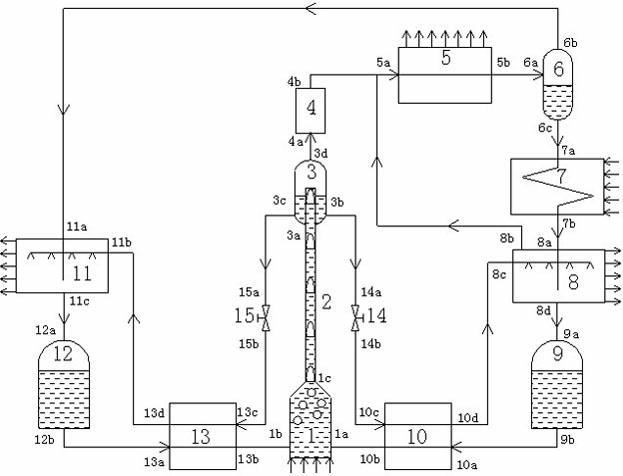

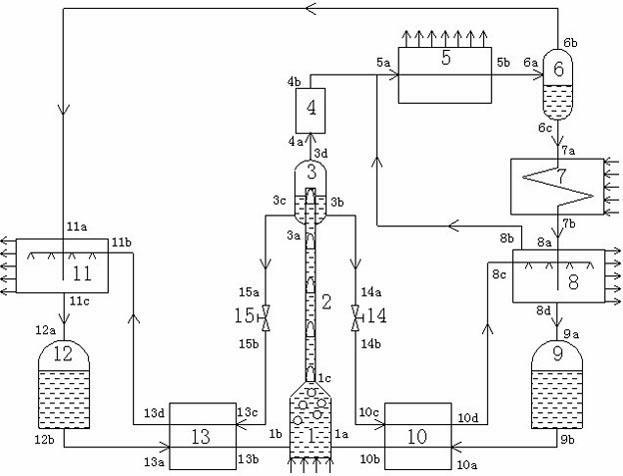

[0014] As shown in the figure, the diffusion-absorption heat exchanger without moving parts includes three parts: the generation separation module, the refrigerant absorption module and the diffusion agent absorption module; the generation separation module includes the generator 1, the riser 2, the first gas-liquid separation module 3, rectifying device 4, condenser 5 and second gas-liquid separator 6; the first port 1a of generator 1 is connected with the second port 10b of first regenerator 10, and the second port 1b of generator 1 It is connected with the second port 13b of the second regenerator 13, the third port 1c of the generator 1 is connected with the bottom inlet of the riser 2, and the top outlet of the riser 2 passes through the first port 3a of the first gas-liquid separator 3 Insert more than 1 / 2 of the height of the first gas-liquid separator 3, the second port 3b of the first gas-liquid separator 3 is connected with the first port 14a of the first regulating v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com