Dynamic loading comprehensive experimental table for gas bearing-rotor system

A technology of gas bearing and system dynamics, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as difficulty in achieving coaxiality, error of gas bearing stiffness measurement results, and inability to guarantee the eccentricity of gas bearing, so as to ensure repeatability and repeatability Strong and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

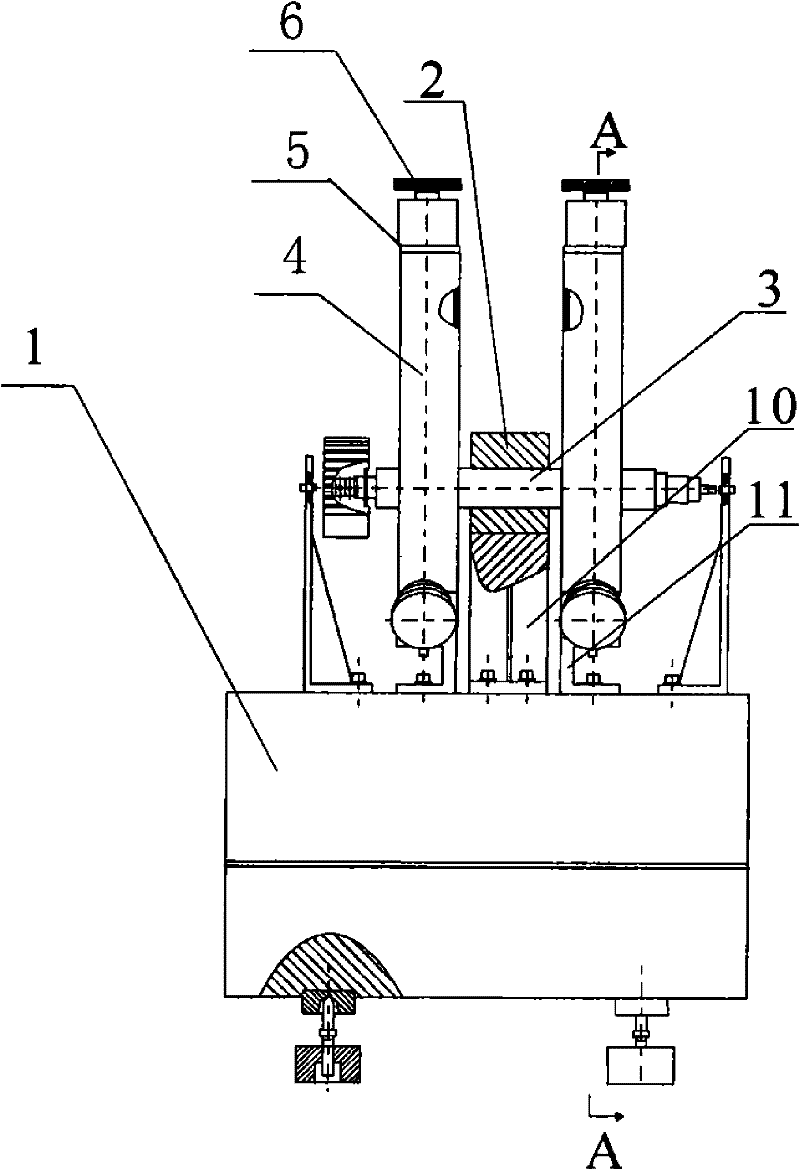

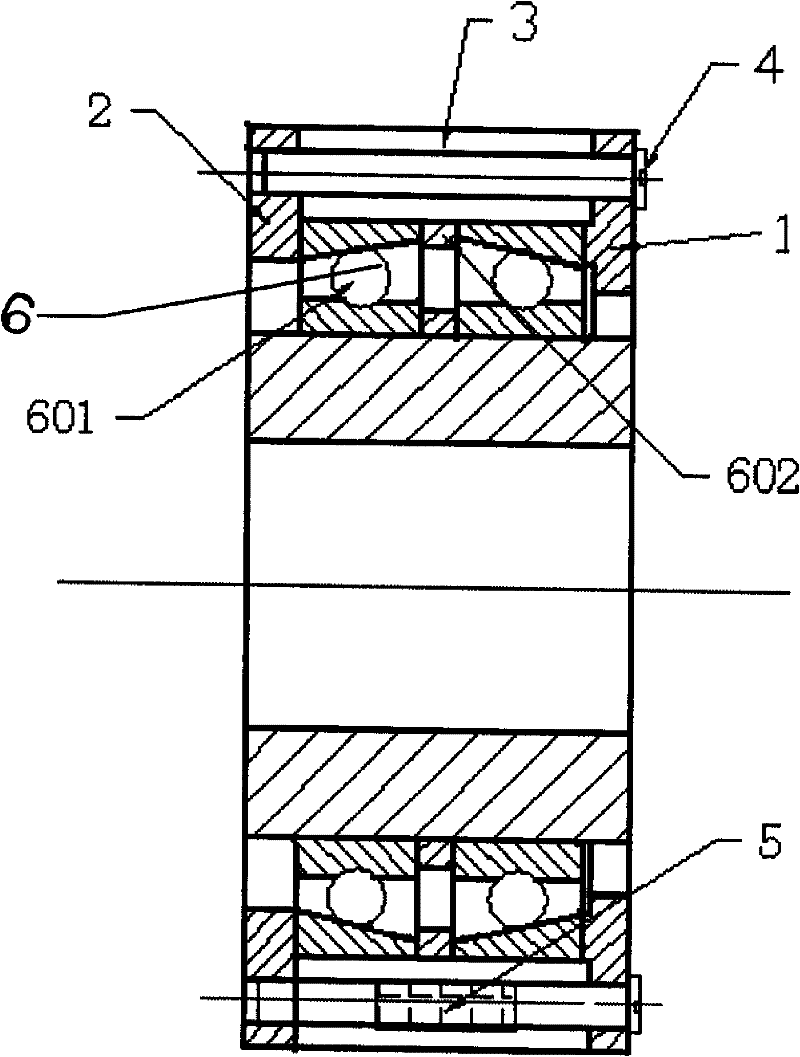

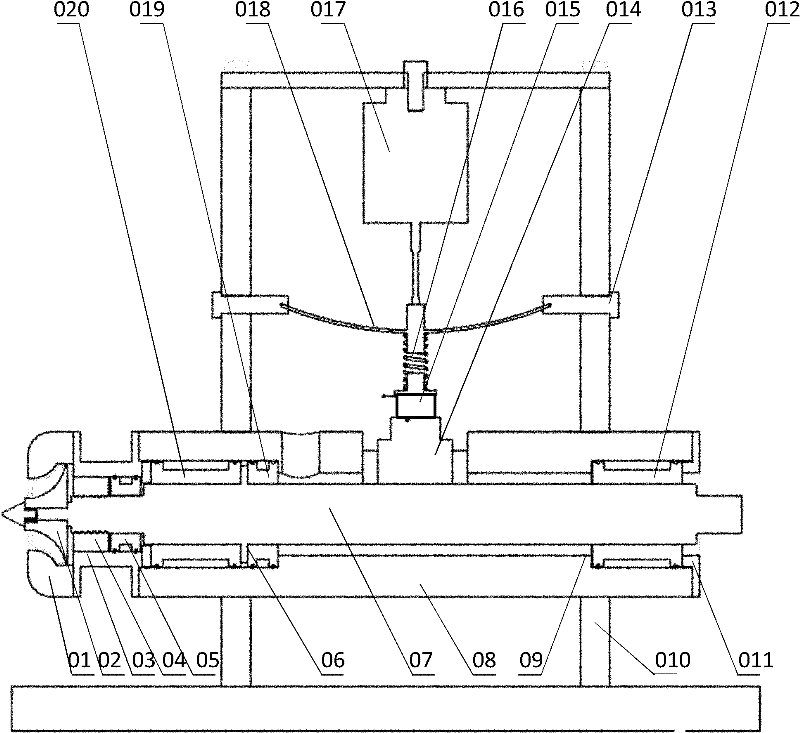

[0049] image 3 It is a schematic structural diagram of the gas bearing-rotor system dynamic loading integrated test bench of the present invention; Figure 4 is a schematic diagram of the tilting pad loading bearing structure; Figure 5 It is a schematic diagram of the bearing disassembly tooling structure. As shown in the figure, the gas bearing-rotor system dynamic loading integrated test bench of the present invention consists of a volute 01, a driving turbine 02, a sealing bracket 03, a labyrinth sealing ring 04, a gas film sealing ring 05, a thrust plate 06, and a rotating shaft 07 , integrated casing 08, boss 09, main support frame 010, cover plate 011, radial gas bearing 012, Charpy beam loading adjustment bolt 013, tilting pad loading bearing 014, force-frequency sensor 015, loading spring 016 , exciter 017, adjustable simply supported beam 018, thrust gas bearing 019, radial-thrust combined gas bearing 020, bearing disassembly tooling 021, etc.; among them, the til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com