Method for forecasting mechanical property of hot-rolled bar wire rod

A technology for the performance of rods and wires, which is applied in the field of mechanical performance prediction of hot-rolled rods and wires, can solve the problems of complicated initial grain size conditions and uneven grain size, so as to reduce performance fluctuations, stabilize steel quality, and improve economic benefits Effect

Inactive Publication Date: 2011-07-13

宣化钢铁集团有限责任公司 +1

View PDF0 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(3) The initial conditions of hot rolling - the severe inhomogeneity of the as-cast structure and grain size of the continuous casting slab, which complicates the initial grain size conditions entered by the model and introduces initial and "genetic" errors

[0004] As far as we know, no steel mill has established a strength model for hot-rolled steel bars and wire rods so far, and has predicted the strength of hot-rolled products of different grades and specifications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0027] A more specific implementation is as follows:

[0028] ① Establish a strength constitutive equation that comprehensively reflects the incremental contribution of each main strengthening mechanism to strength.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

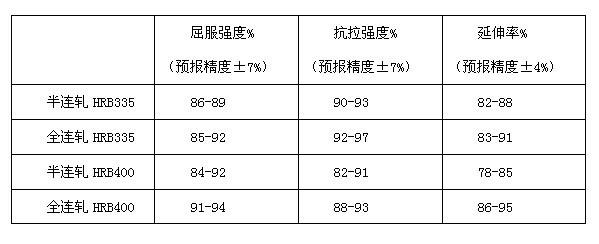

The invention relates to a method for forecasting the mechanical property of a hot-rolled bar wire rod, belonging to the technical field of a mathematical model for forecasting the performance of metallurgy industry products. The technical scheme is as follows: (1) building a strength constitutive equation which comprehensively reflects contribution increment on the strength by a reinforcement mechanism; (2) building a microstructural evolution model of hot-rolled steel bar and wire rods; and (3) building a computer model, and forecasting the strength performance of the hot-rolled steel bar and wire rods. The method has the beneficial effect that the mathematical model for forecasting the mechanical property of a hot-rolled bar wire rod is built; chemical components for steelmaking are optimally designed, and the protection technology for steelmaking and steel rolling is optimally controlled; under the condition of lowering iron alloy addition, the steel performance fluctuation is reduced, the steel quality is stabilized, and the economic benefit for producing the hot-rolled bar wire rods is improved. The forecasting hit rate of yield strength is 82-94%, the forecasting hit rate of tensile strength is 82-97%, and the forecasting hit rate of elongation rate is 78-95%.

Description

technical field [0001] The invention relates to a method for predicting the mechanical properties of hot-rolled rods and wires, and belongs to the technical field of mathematical models for product performance prediction in the metallurgical industry. Background technique [0002] Hot-rolled steel is the most widely used engineering structural material, and its yield strength is one of the most important bases for calculating structural strength and allowable stress, and it is also one of the most important criteria for hot-rolled steel to meet various special steel technical standards. Over the past 30 years, countries around the world have invested a lot of technical force and funds to research and develop the structure and performance prediction models of hot-rolled strips, and have done a lot in basic physical metallurgical experiments and models, hot-rolling process technology, computer software and models. work and made significant progress. At present, there have bee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F19/00

Inventor 张海底根顺马立明王宏斌王勇冯建航张文俊张燕平张彦荣贾建平张艳萍

Owner 宣化钢铁集团有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com