Conformal coating shielding method of circuit board

A circuit board and conformal paint technology, applied in the field of painting, can solve the problems of difficult mold design and operation, poor shielding effect, etc., achieve high production efficiency, improve production efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

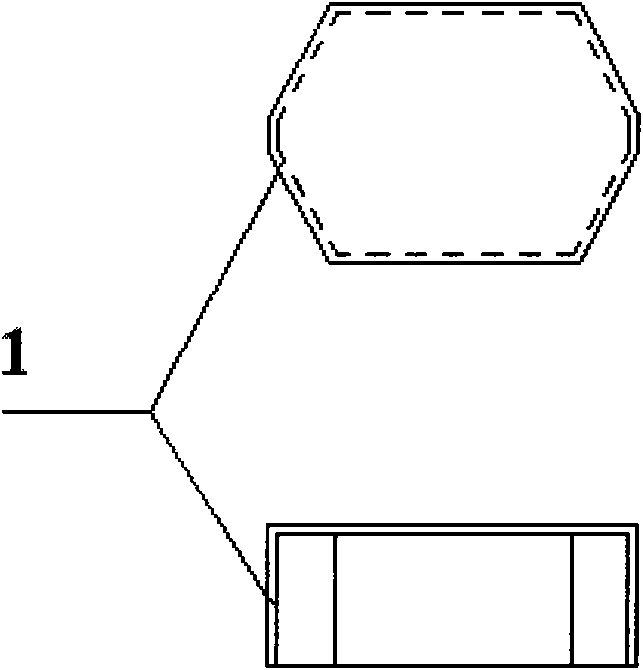

[0040] Such as figure 1 As shown, according to the geometric shape and size of the radiator on the circuit board, the masking rubber sleeve is made. Before coating, the masking rubber sleeve is placed on the radiator, and then the conformal paint is applied. The masking rubber sleeve has a shielding effect and ensures The radiator is not polluted by the conformal paint, and the heat dissipation effect is not affected.

Embodiment 2

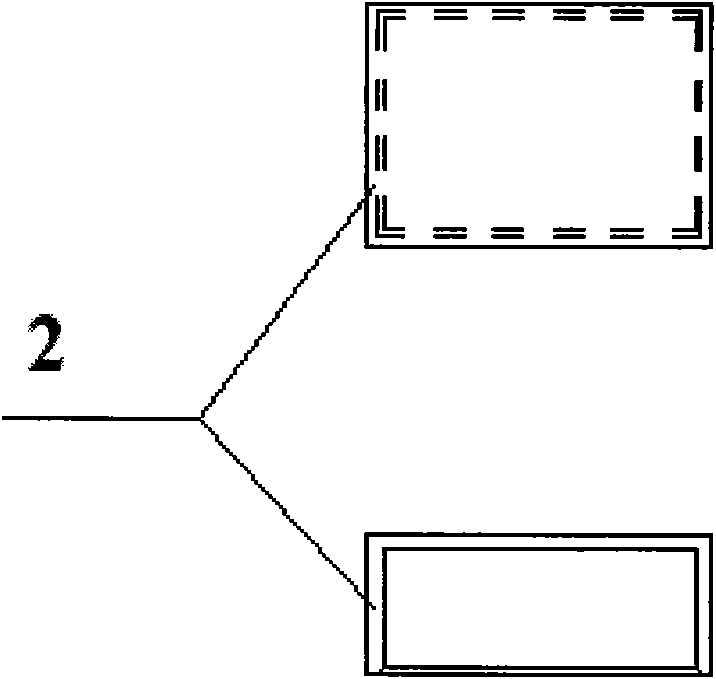

[0042] Such as figure 2 As shown, according to the geometric shape and size of the digital display module on the circuit board, the masking rubber sleeve is made. Before coating, the masking rubber sleeve is placed on the digital display module, and then the conformal paint is applied. The masking rubber sleeve has a shielding effect. , to ensure that the digital display module is not polluted by the three anti-paint, and does not react with the three anti-paint, thereby ensuring the display effect of the digital display module.

Embodiment 3

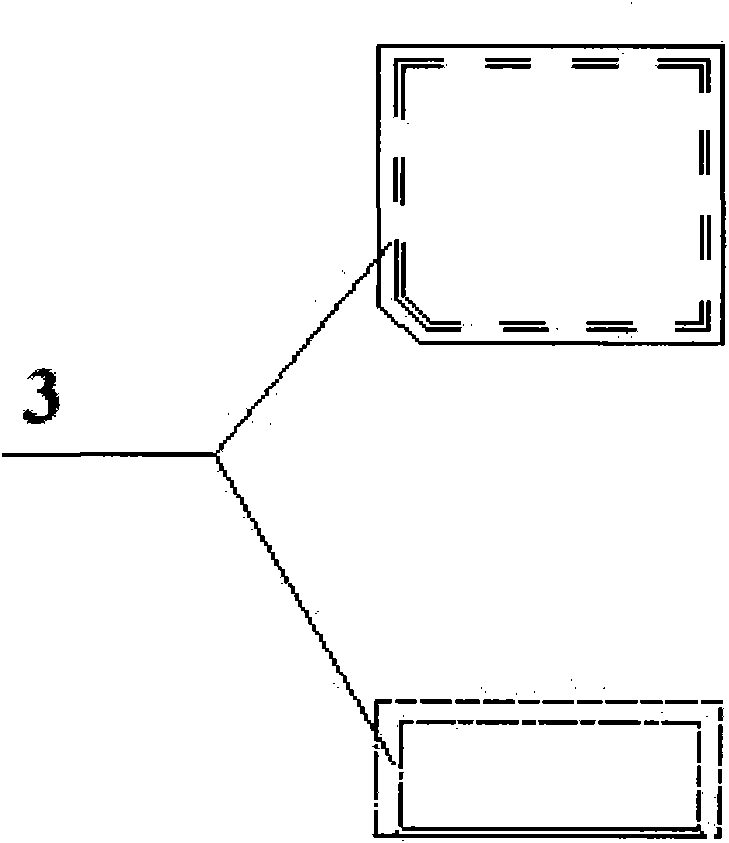

[0044] Such as image 3 As shown, the masking rubber sleeve is made according to the geometry and size of the AMP socket on the circuit board. The three-proof paint will not climb to the pins due to capillary phenomenon, so as to ensure that the device pins on the socket will not be insulated from the socket pins due to the pollution of the three-proof paint, which will affect the conduction performance of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com