Coreless paper roll rewinder

A technology of rewinding machine and paper roll, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of unstable force, high cost, lack of supporting force, etc., to improve production efficiency, manufacturing Low cost and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

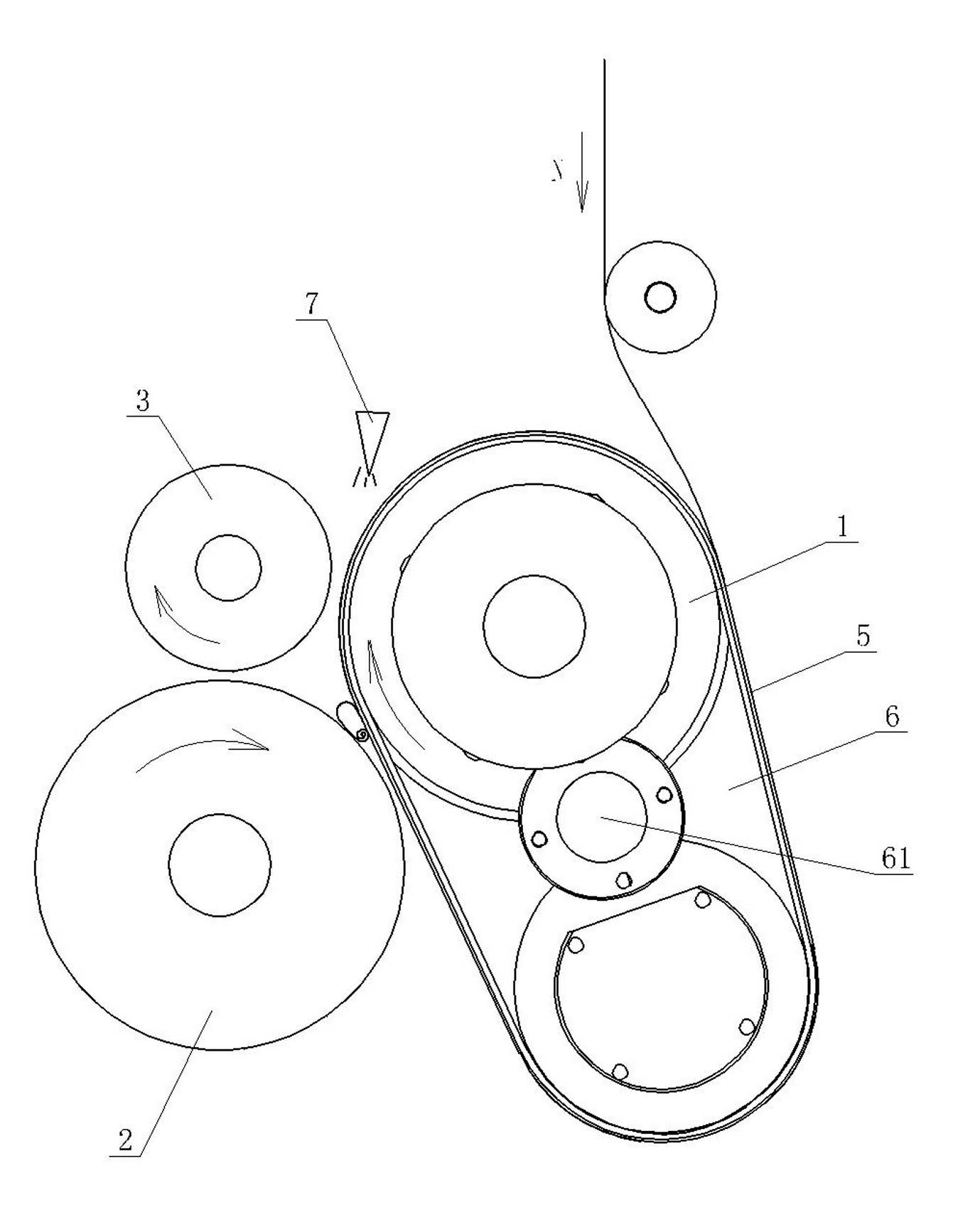

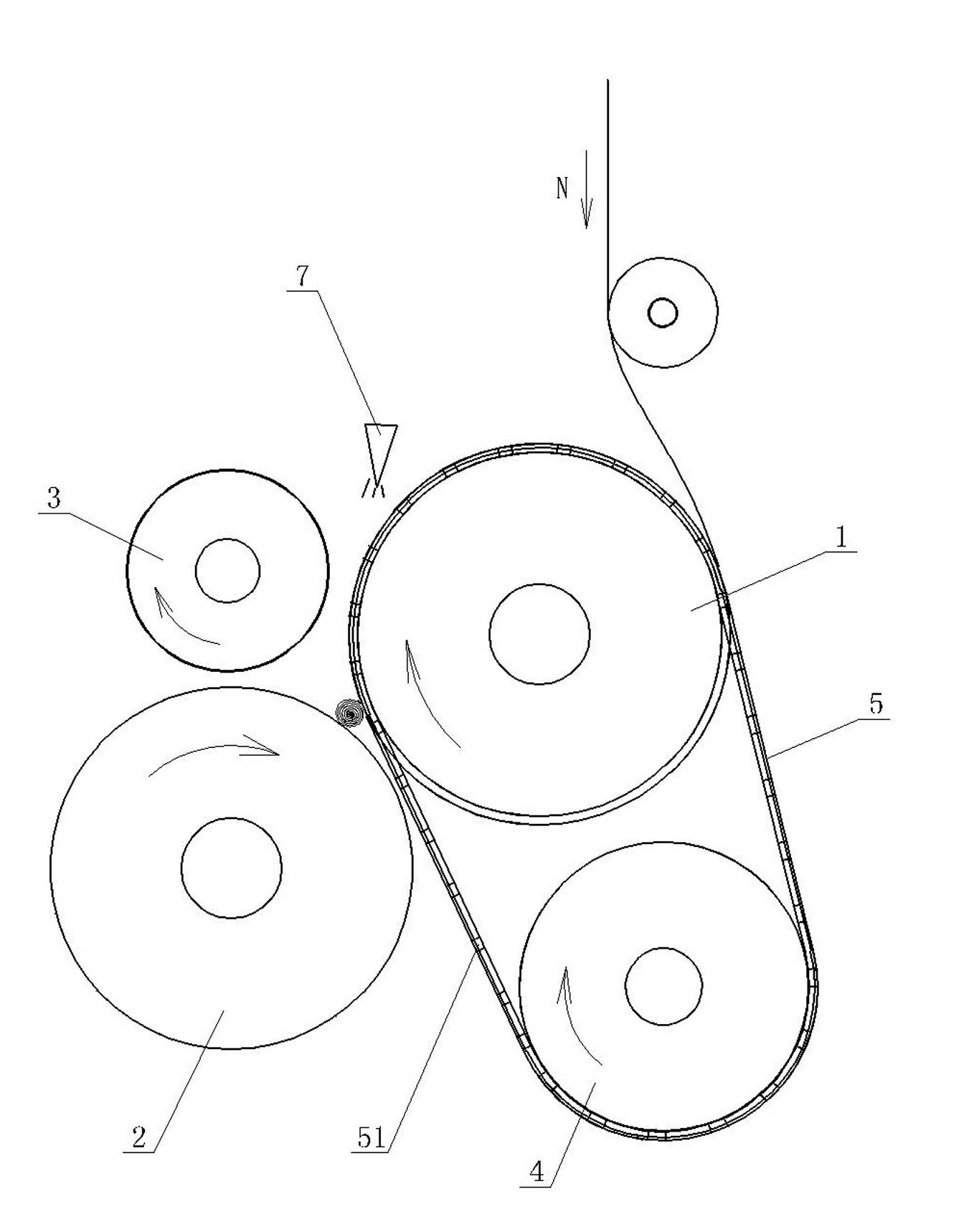

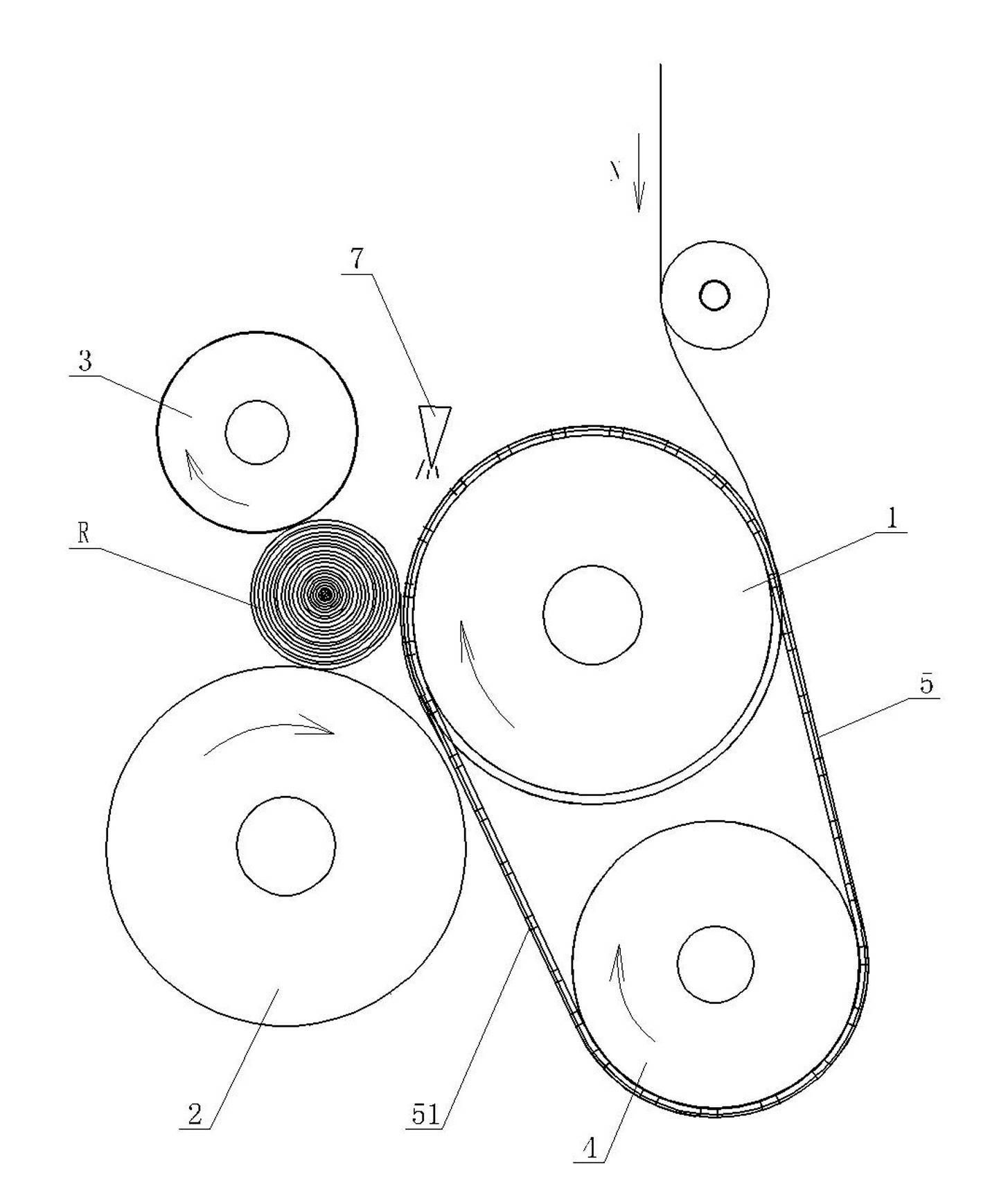

[0014] Such as Figure 1 to Figure 6 As shown, a coreless paper roll rewinding machine according to the present invention mainly includes an upper rewinding roller 1, a lower rewinding roller 2, and a pressure roller 3, and a downward blowing blowpipe 7 is arranged above the upper rewinding roller 1. , wherein the upper rewinding roller 1 is provided with a drum 4, and a winding belt 5 that can move synchronously with the upper rewinding roller 1 is connected between the cylinder 4 and the upper rewinding roller 1, and the winding belt 5 is connected with the lower rewinding roller 1. A trumpet-shaped space with gradually enlarged opening is defined between the rewinding rollers 2 as the winding area for coreless paper rolls, and a space formed between the winding belt 5 and the upper rewinding roller 1 and the drum 4 is equipped with a Vacuum chamber 6, said take-up belt 5 is densely covered with a number of vacuum suction holes 51 communicating with the vacuum chamber 6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com