Self-tightening sealed optical glass window of constant volume bomb

An optical glass, self-tightening sealing technology, applied in the sealing of engines, internal combustion engine testing, engine components, etc., can solve the problems of easy damage of optical glass, failure of sealing gaskets, poor sealing effect, etc., to enhance the sealing effect, sealing Improve performance and solve the effect of frequent replacement of gaskets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

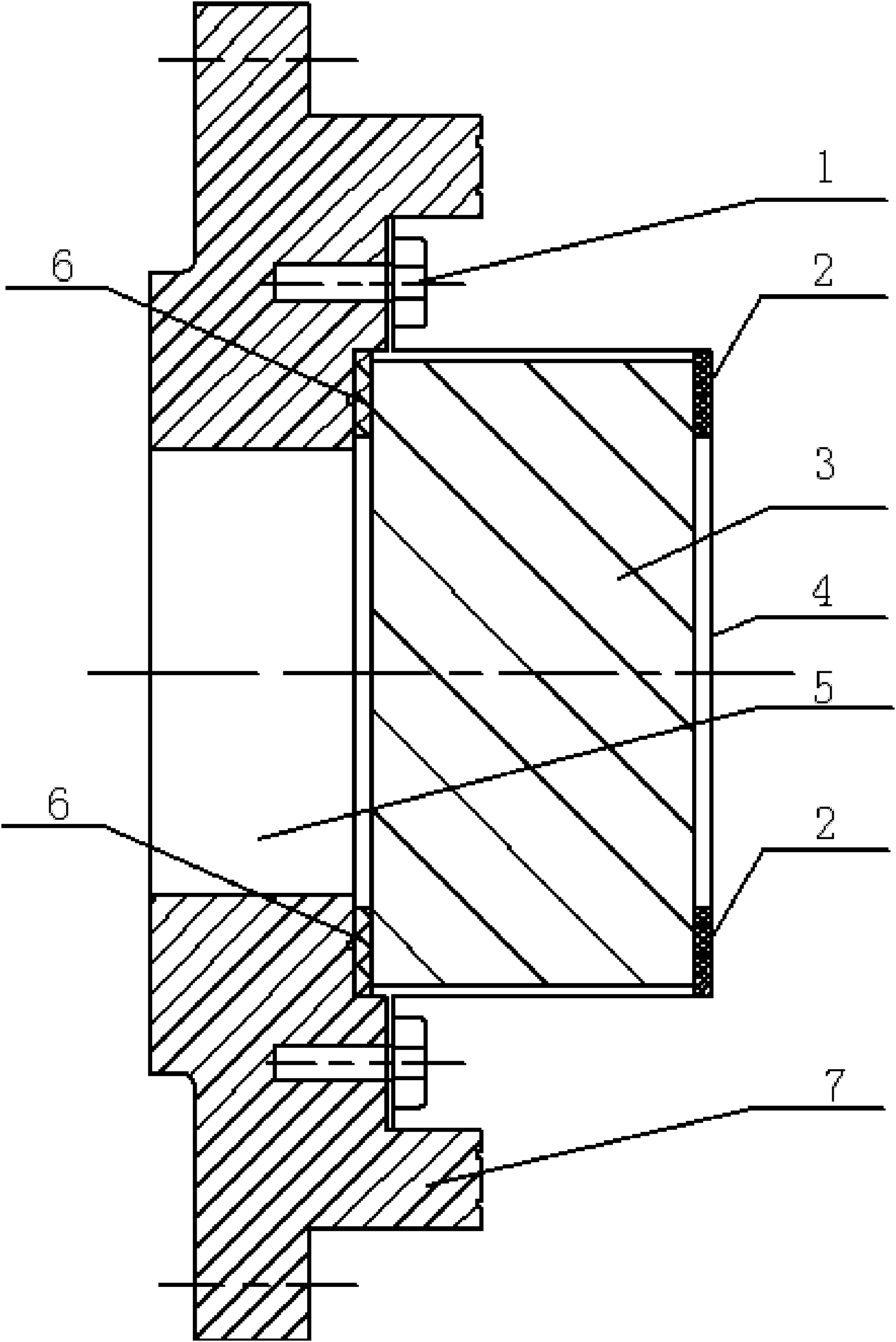

[0026] The self-tightening and sealing type constant volume bullet optical glass window of the present invention comprises end cap 7, sleeve 4, optical glass 3, bolt 1, second gasket 2 and first gasket 6, as figure 1 shown.

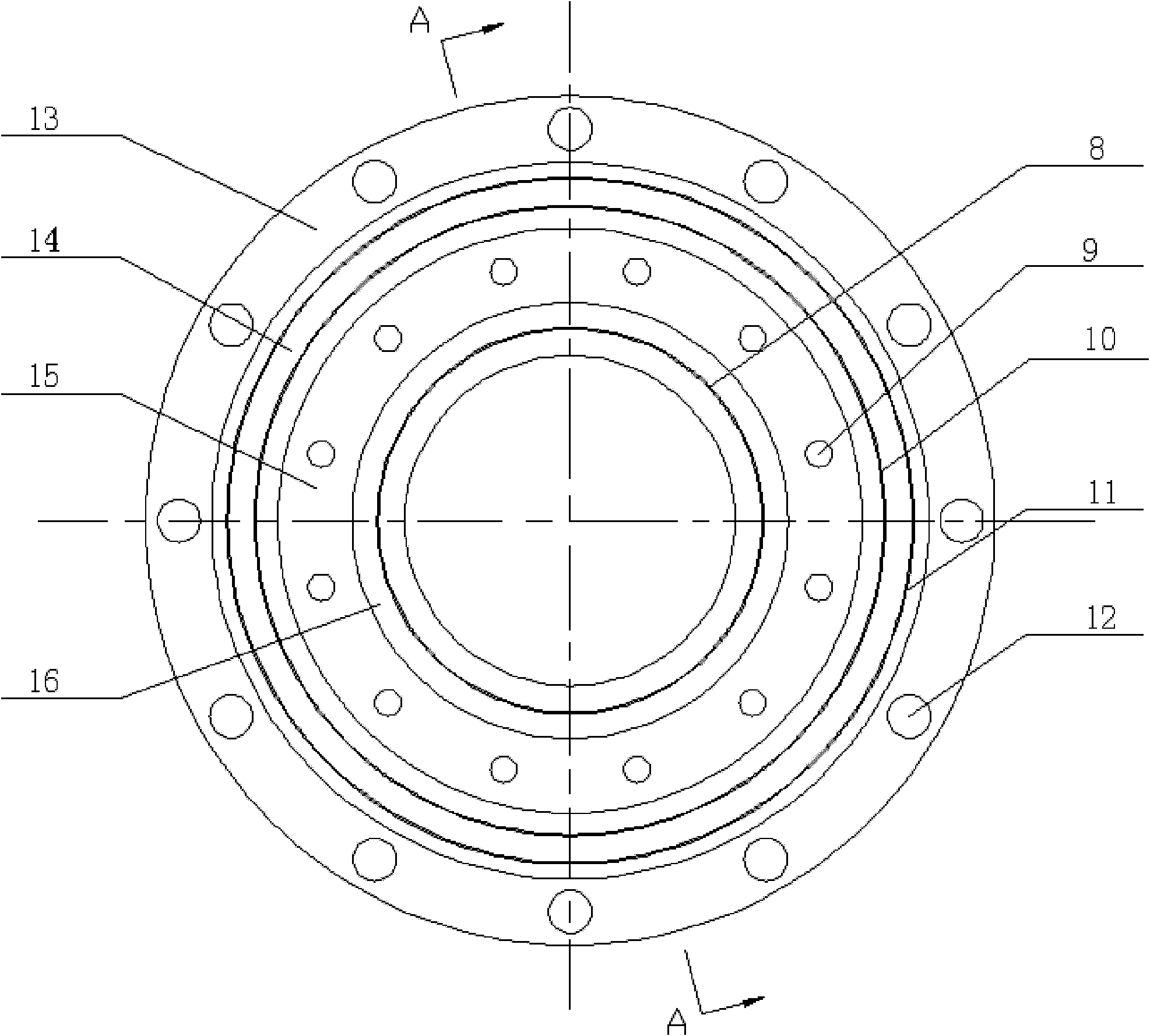

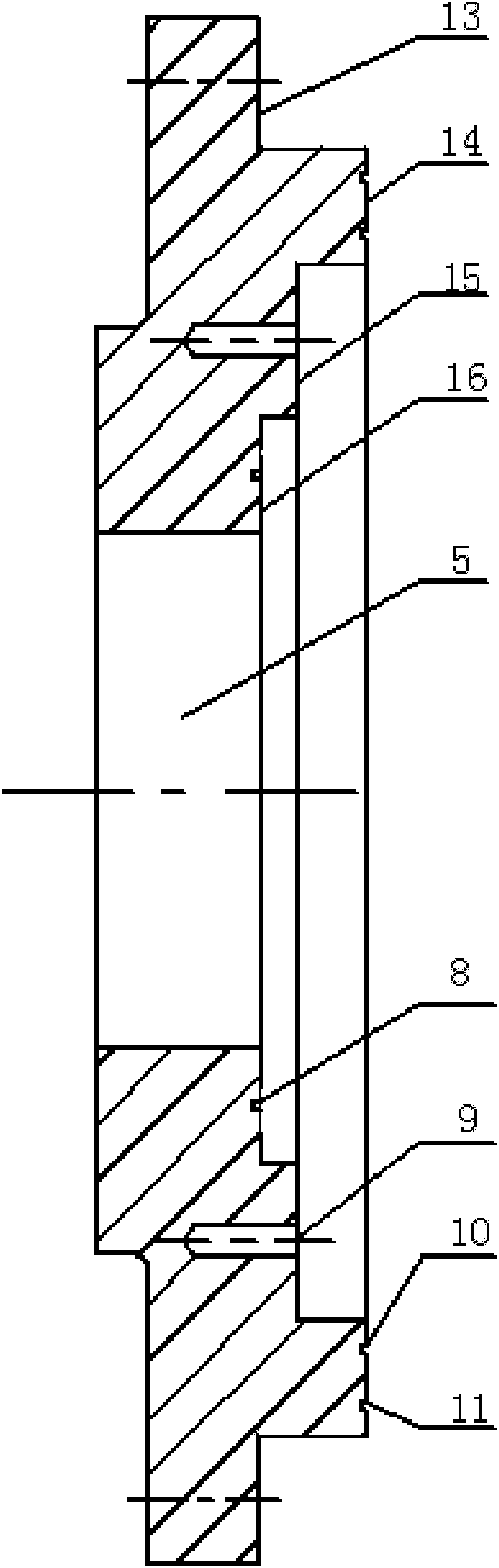

[0027] The end cover includes observation hole 5, three-stage stepped end faces (cylindrical ring protruding end face 14, threaded hole end face 15, optical glass sink hole seat end face 16) and outer edge 13, such as figure 2 and image 3 shown. The inner diameter of the observation hole 5 is 100 mm, and there are two square-section seal ring grooves with a side length of 0.5 mm on the protruding end face 14 of the cylindrical ring, which are the sealing ring grooves 10 of the protruding end face of the first cylindrical ring and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com