Integrated optical fiber laser collimator and manufacturing device thereof

A fiber laser and collimator technology, applied in optics, instruments, optical components, etc., can solve problems such as easily damaged fiber end faces, installation and adjustment errors, detection and manufacturing asynchronous, etc., to reduce optical energy loss and damage threshold, Reduce the scrap rate and ensure the synchronous effect of production and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

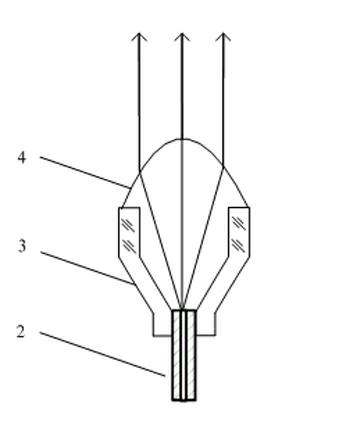

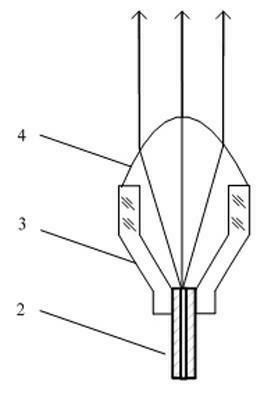

[0019] See figure 1 , The integrated fiber laser collimator includes a laser 1 and an optical fiber 2. One end of the optical fiber 2 is connected to the laser 1, the other end of the optical fiber 2 is connected to a bucket-shaped sleeve 3, and the end of the optical fiber 2 extends into the sleeve 3. The maximum inner diameter of the bucket-shaped casing is 5mm. The casing 3 is provided with a droplet lens 4, the bottom of the droplet lens 4 is connected to the optical fiber 2, and the top shape of the droplet lens 4 is curved and is located outside the casing 3.

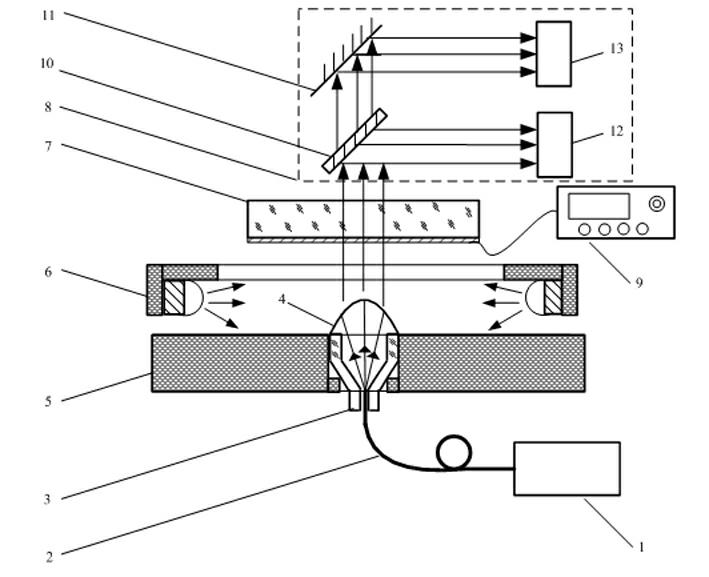

[0020] See figure 2 , A device for preparing an integrated fiber laser collimator includes a transparent or mesh upper electrode 7, a lower electrode 5, a high voltage AC and DC power supply 9, a curing mechanism and a beam divergence angle detection device 8. A through hole is opened in the middle of the lower electrode 5, and a positioning convex ring is installed in the lower port of the through hole; the curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com