Power electronic rectification transformer

A technology of rectifier transformer and power electronics, which is applied in the direction of adjusting electric variables, instruments, and converting DC power input to DC power output. It can solve the problems of increasing the use cost of rectifier transformers and complex design of rectifier transformers, so as to simplify installation and production. and installation, the effect of reducing harmonic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

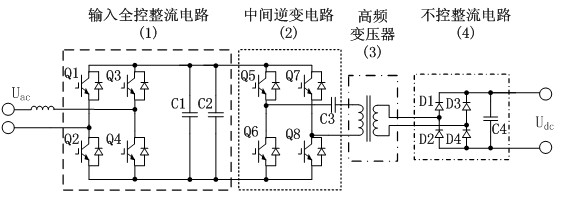

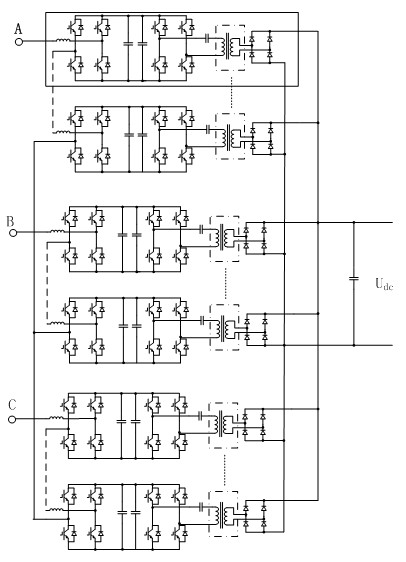

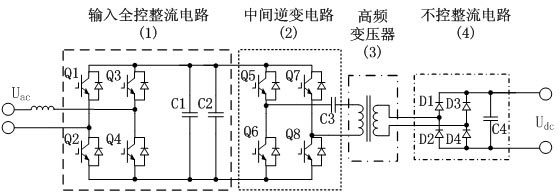

[0013] figure 2 As shown, each phase circuit on the three-phase input side is formed by connecting N identical power units in series, and the DC output side is formed by connecting the outputs of all three-phase power units in parallel. The main structure of each power unit includes: input fully controlled rectifier circuit, intermediate inverter circuit, high frequency transformer and uncontrolled rectifier circuit. The three-phase alternating current on the input side is connected in a star-shaped manner, and the N power unit input terminals of each phase are connected in series to adapt to different input voltage levels. The output terminals of all three-phase power units are connected in parallel to the DC output bus capacitor. figure 1 As shown, in each power unit, the output terminal of the input full-control rectifier circuit 1 is connected to the input terminal of the intermediate inverter circuit 2, and the output terminal of the intermediate inverter circuit 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com