Heater for bulk curing barn

A technology of intensive roasting room and heater, which is applied to the field of heaters of intensive roasting room, can solve the problems of insufficient combustion of coal, low heat exchange efficiency, and insufficient heat utilization, and achieves compact structure and good heat exchange effect. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

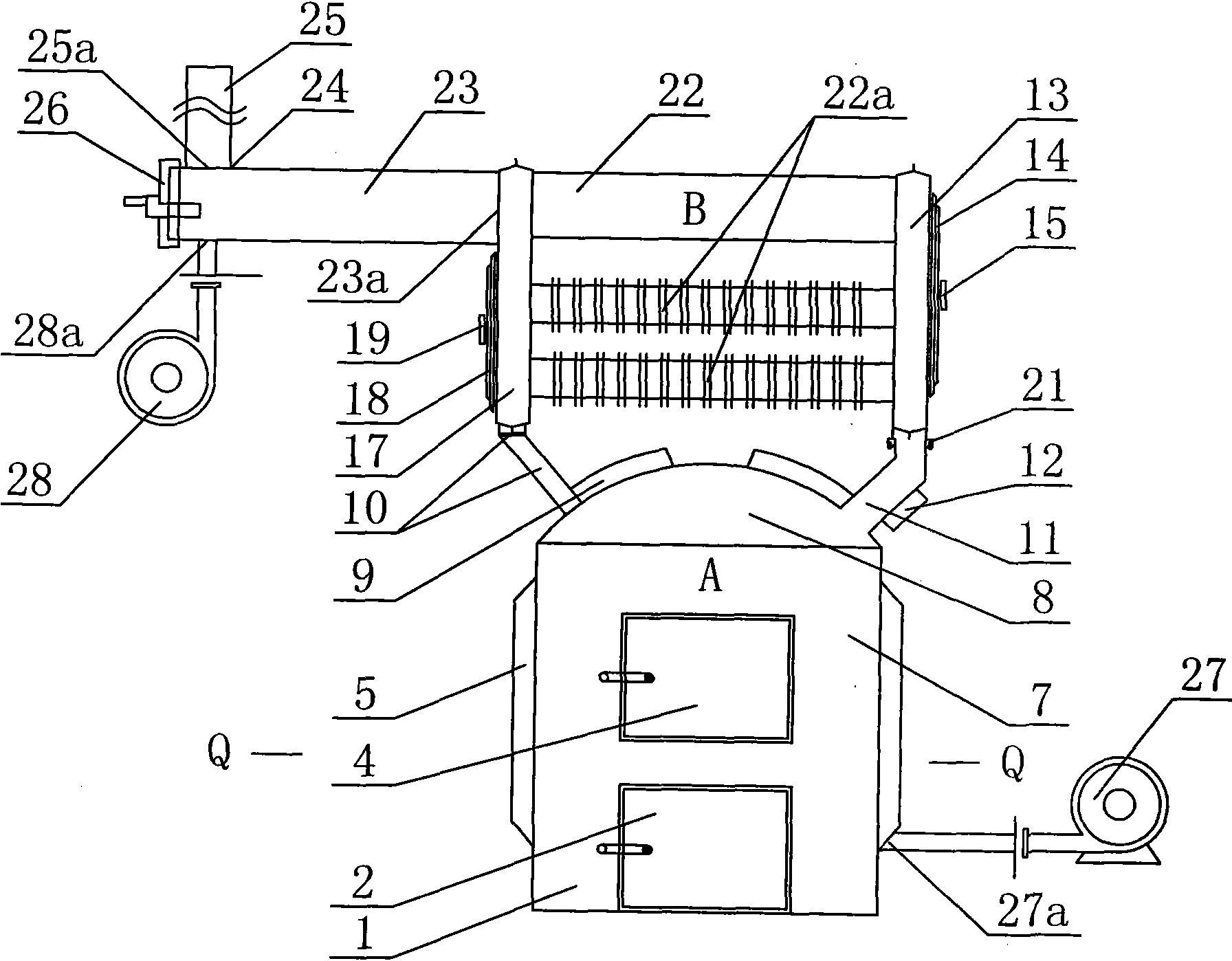

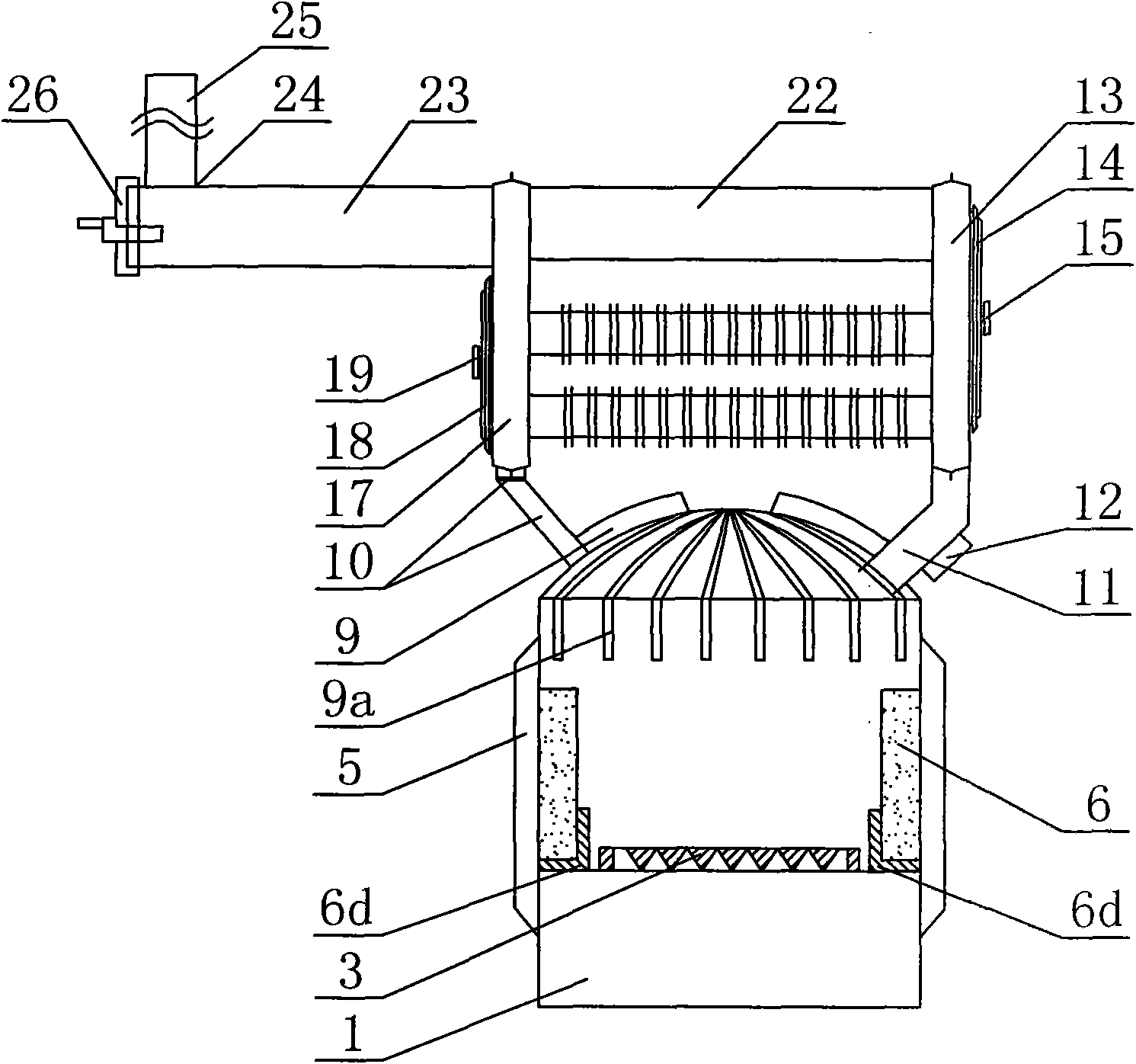

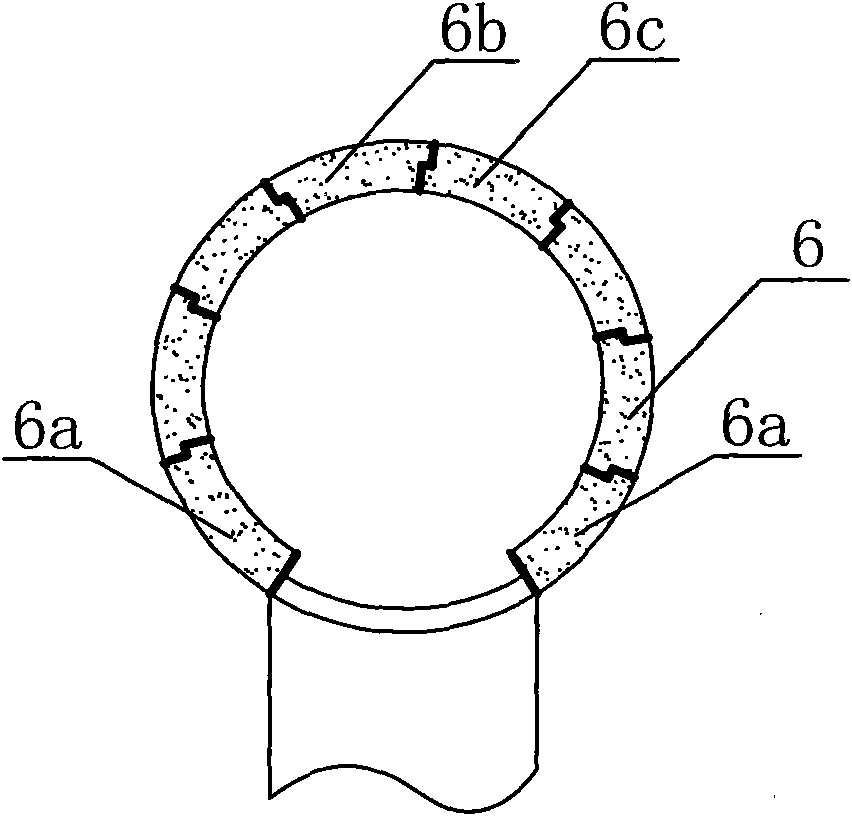

[0019] A heater for a dense barn, including a heating furnace A and a heat exchanger B. A furnace door frame opening is provided on the furnace body 1 of the heating furnace A, and a furnace door 4 is placed on it, and a fire grate 3 is arranged in the furnace body 1 , a refractory lining 6 is placed on the furnace inner wall at the upper part of the grate, the upper part of the furnace body 1 is a furnace top head 8, the lower part of the furnace body 1 is an ash pit, and there is a coal ash outlet on the ash pit, and an ash pit is arranged on it The door 2 is provided with a blast port 27a on one side of the wall of the ash pit, and a positive pressure combustion-supporting fan 27 is provided here; The secondary air inlet channel 5; the heat exchanger B is composed of two left and right fire boxes and a heat exchange tube 22 that is located between the two fire boxes and communicates with them. The ash opening, the left ash removal door 18 is housed on it, the right ash remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com