Motorized high-speed hydraulic compacting machine

A mobile, tamping machine technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of reducing the impact force of the target foundation, frequent oil leakage of hydraulic cylinders, poor tamping effect, etc., to reduce production and construction costs , energy saving, high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The motorized high-speed hydraulic compactor provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

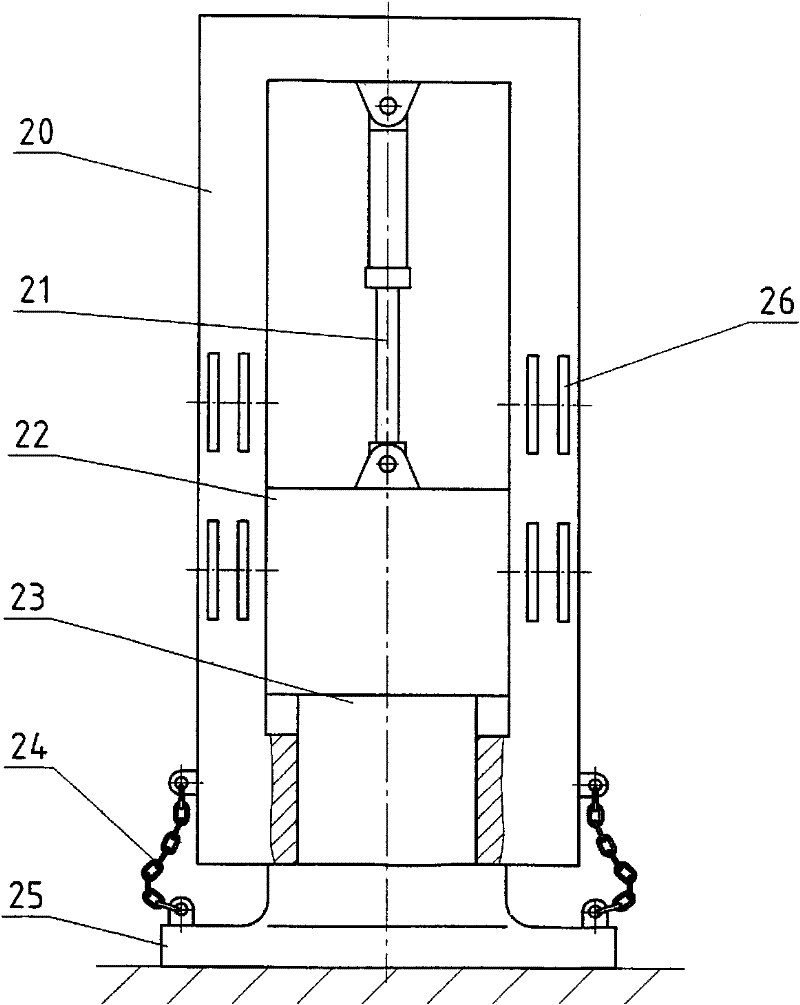

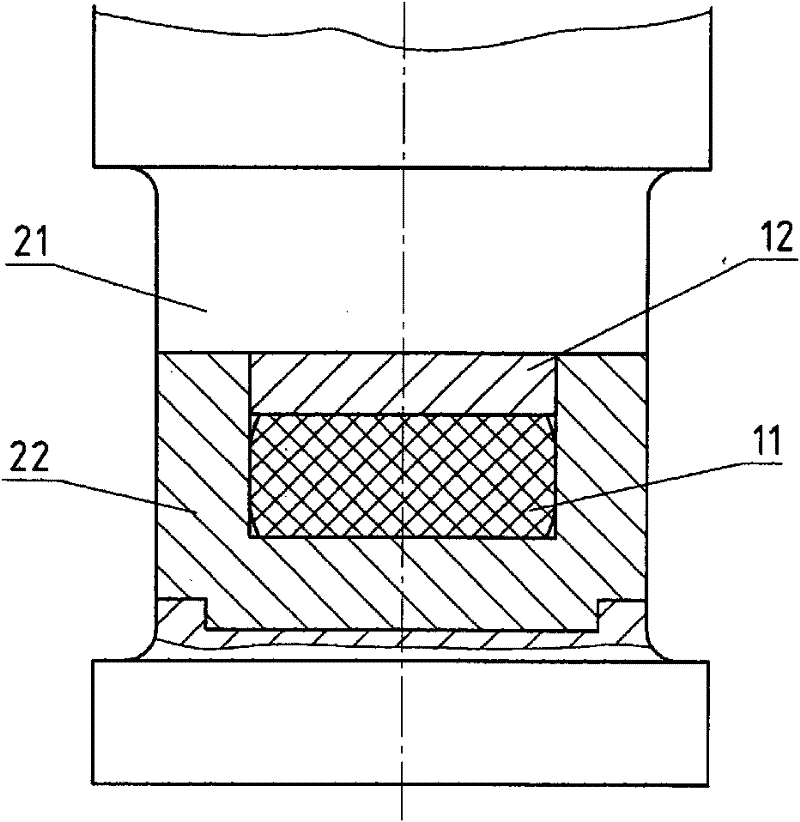

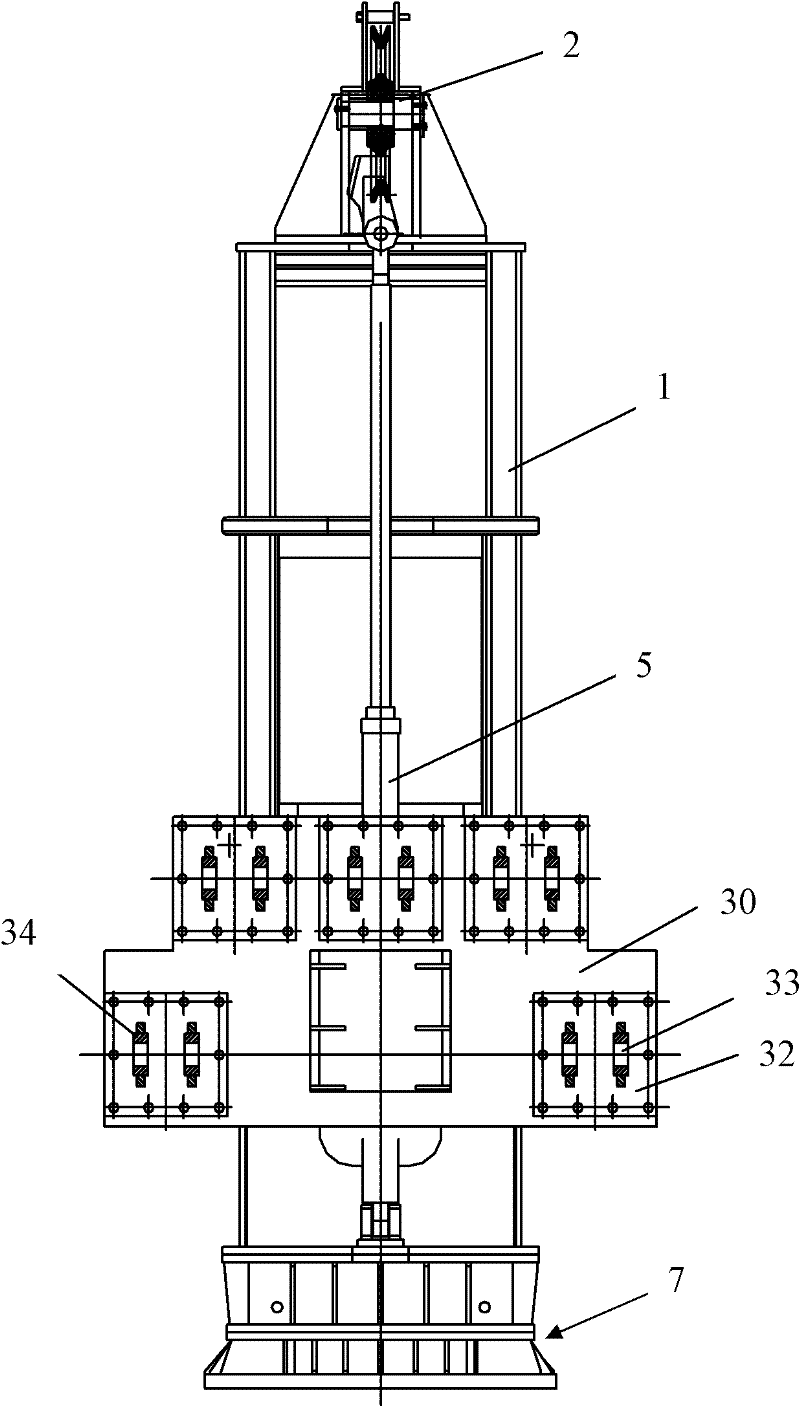

[0021] Such as Figure 3-Figure 8 As shown, the motorized high-speed hydraulic ramming machine provided by the present invention includes a ramming frame 1, a pulley device 2, a steel wire rope 3, a ramming hammer 4, a hydraulic cylinder 5, a transition seat 9, a tamping seat 7, a plurality of guard plates 8 and two long Pin shaft 51; wherein: the rammer frame 1 is a cube-shaped frame structure, used to support the rammer 4 and the hydraulic cylinder 5, and simultaneously serves as a guide device for the rammer 4; the pulley device 2 is installed on the top of the rammer frame 1; the rammer 4 is It is arranged in the ramming hole on the ram frame 1 in a way that can vertically reciprocate, and it is composed of an upper hammer body 14 and a lower hammer body 15 connected to each other, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com