Device and method for measuring aperture of foamed aluminum based on machine vision

A measuring device and machine vision technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as large human errors, achieve the effect of intuitive and simple methods, accurate data, and eliminate errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

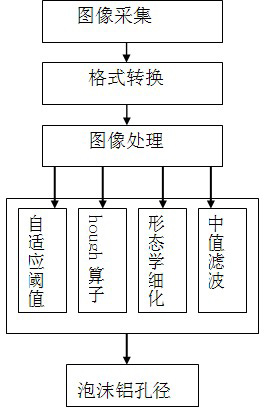

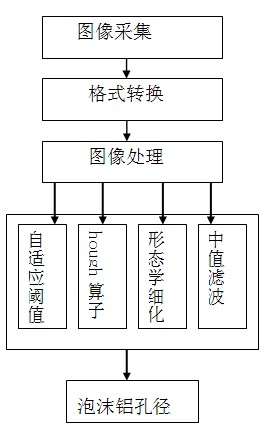

Method used

Image

Examples

specific Embodiment approach

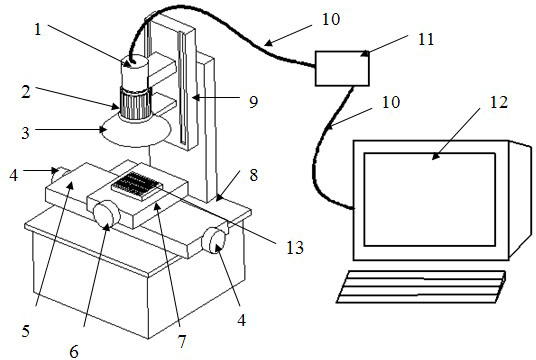

[0018] A device and method for measuring the aperture of foamed aluminum based on machine vision, the device includes an imaging working machine 8, an optical fiber signal transmitter 11 and a computer 12, and the described imaging working machine 8, optical fiber signal transmitter 11 and computer 12 are electrically connected sequentially through the image signal transmission cable 10; the X-axis workbench 5 is arranged on the upper surface of the image-taking working machine 8, and the Y-axis workbench 7 is arranged under the X-axis workbench 5; One side of the working machine 8 fuselage is provided with a column 9, and the camera equipment is installed on the side of the column 9 facing the workbench; the camera equipment is connected and installed in sequence by the camera 1, the optical lens 2 and the LED light source 3, and the working surface is facing Working table, the camera 1 is a high-definition camera 1 for shooting images, the optical lens 2 can adjust the focus,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com