Conductive paste and method for producing electronic components

A technology of electronic parts and manufacturing methods, which is applied to parts of fixed capacitors, conductive materials dispersed in non-conductive inorganic materials, fixed capacitor electrodes, etc., can solve problems such as difficulties and achieve the effect of suppressing structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below based on the embodiments shown in the drawings.

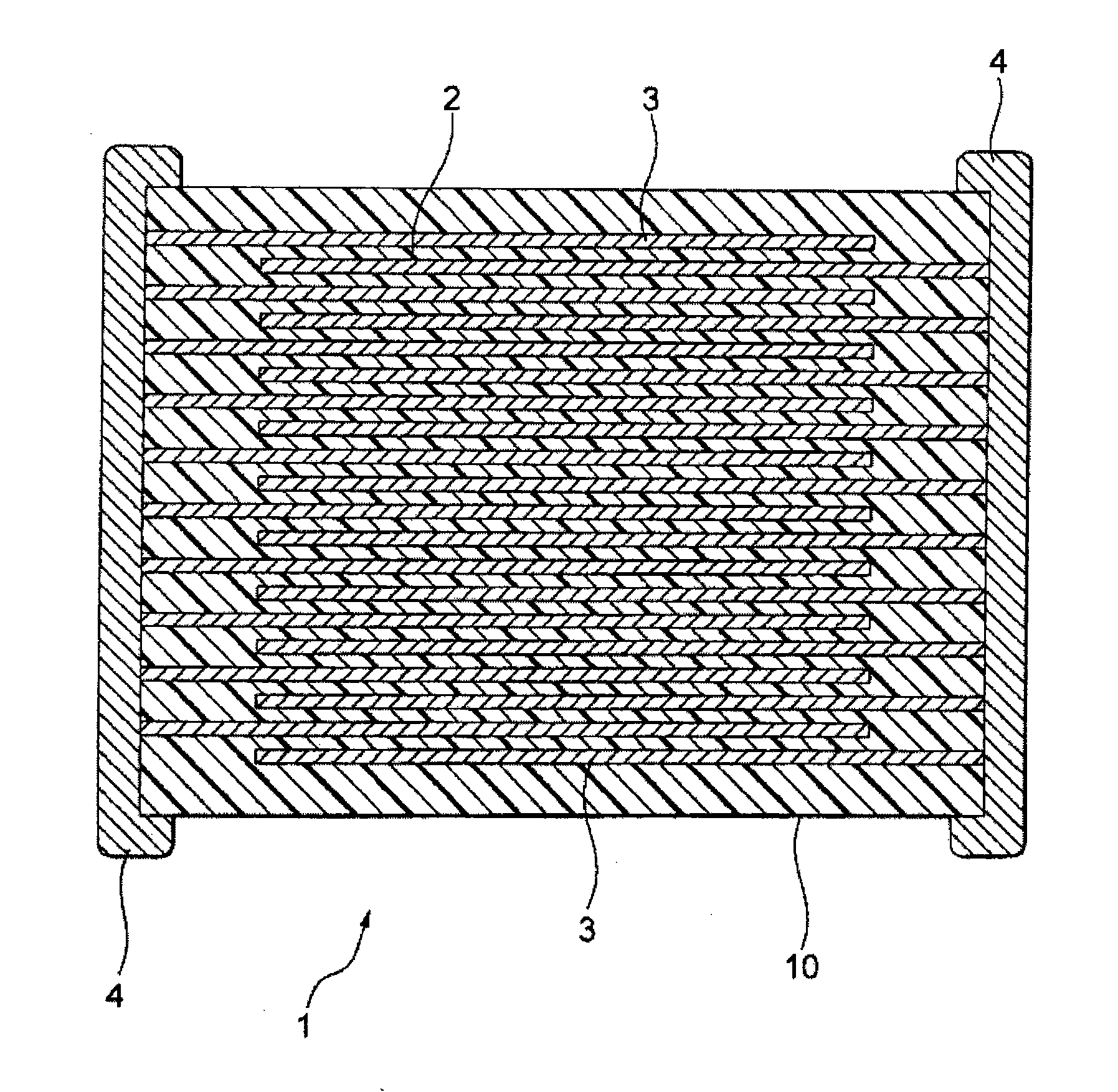

[0029] Multilayer Ceramic Capacitors 1 Such as figure 1 As shown, the multilayer ceramic capacitor 1 according to the first embodiment of the present invention has a capacitor element main body 10 in which dielectric layers 2 and internal electrode layers 3 are alternately laminated. At both ends of the capacitor element body 10 , a pair of external electrodes 4 electrically connected to the internal electrode layers 3 alternately arranged inside the capacitor element body 10 are formed.

[0030] The internal electrode layers 3 are laminated so that the respective end faces are alternately exposed on the surfaces of the opposite end portions of the capacitor element main body 10 . Furthermore, a pair of external electrodes 4 are formed at both ends of the capacitor element main body 10 and connected to exposed end surfaces of the alternately arranged internal electrode lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com