Heat exchanger and method of manufacturing same

A technology of heat exchanger and manufacturing method, which is applied in the direction of heat exchange equipment, heat transfer modification, electric solid devices, etc., can solve the problems that the cooling performance cannot be improved, and the heat of the heating element is difficult to dissipate, so as to achieve mass production, structure and Simple processing and improved cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

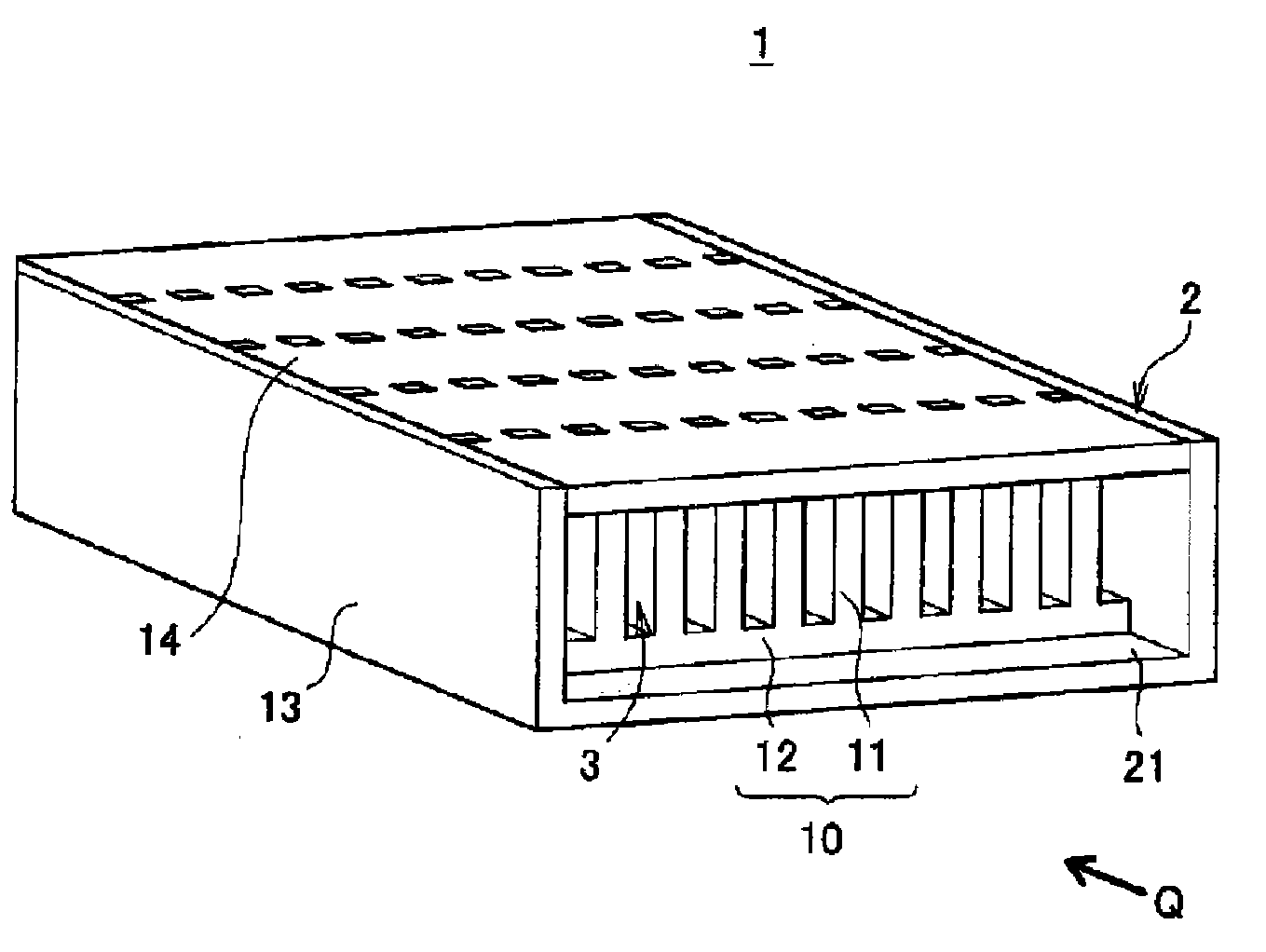

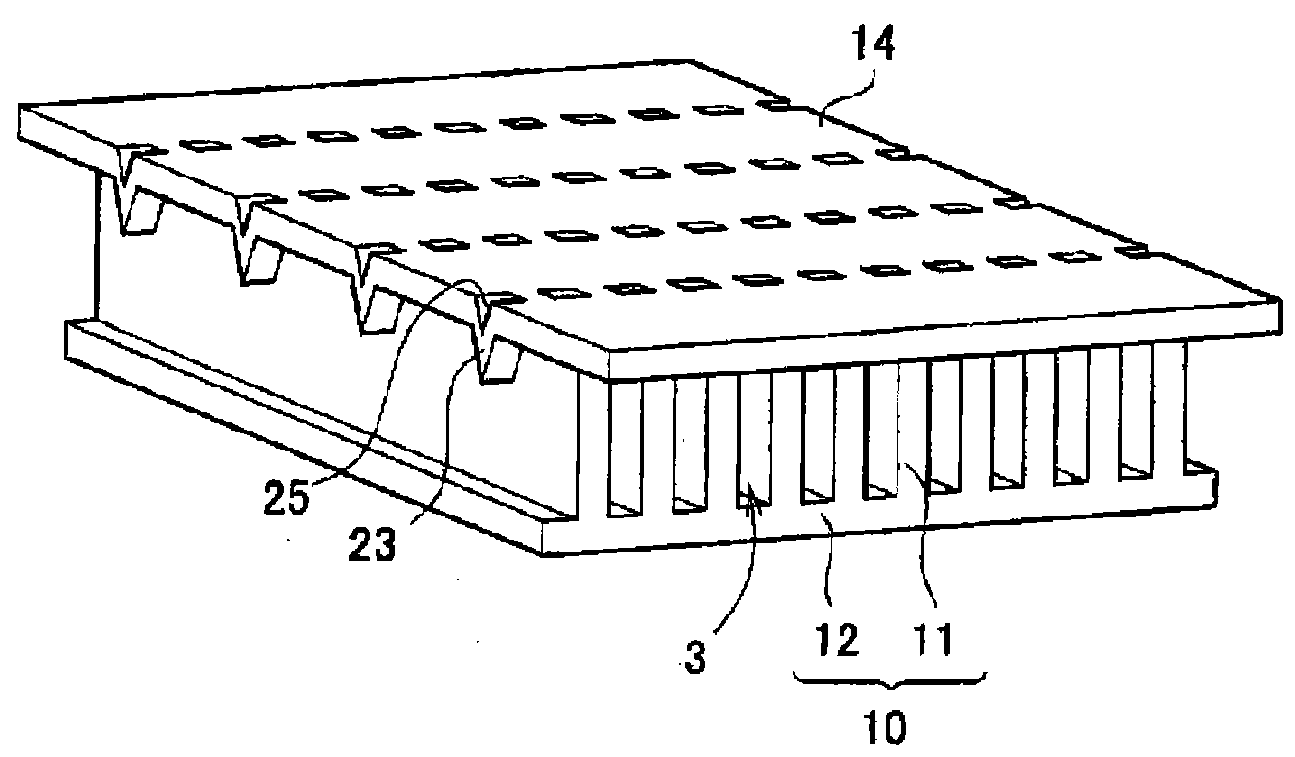

[0055] Next, one embodiment of the heat exchanger and its manufacturing method in the present invention will be described below with reference to the drawings. figure 1 It is a perspective view which shows the heat exchanger of this embodiment.

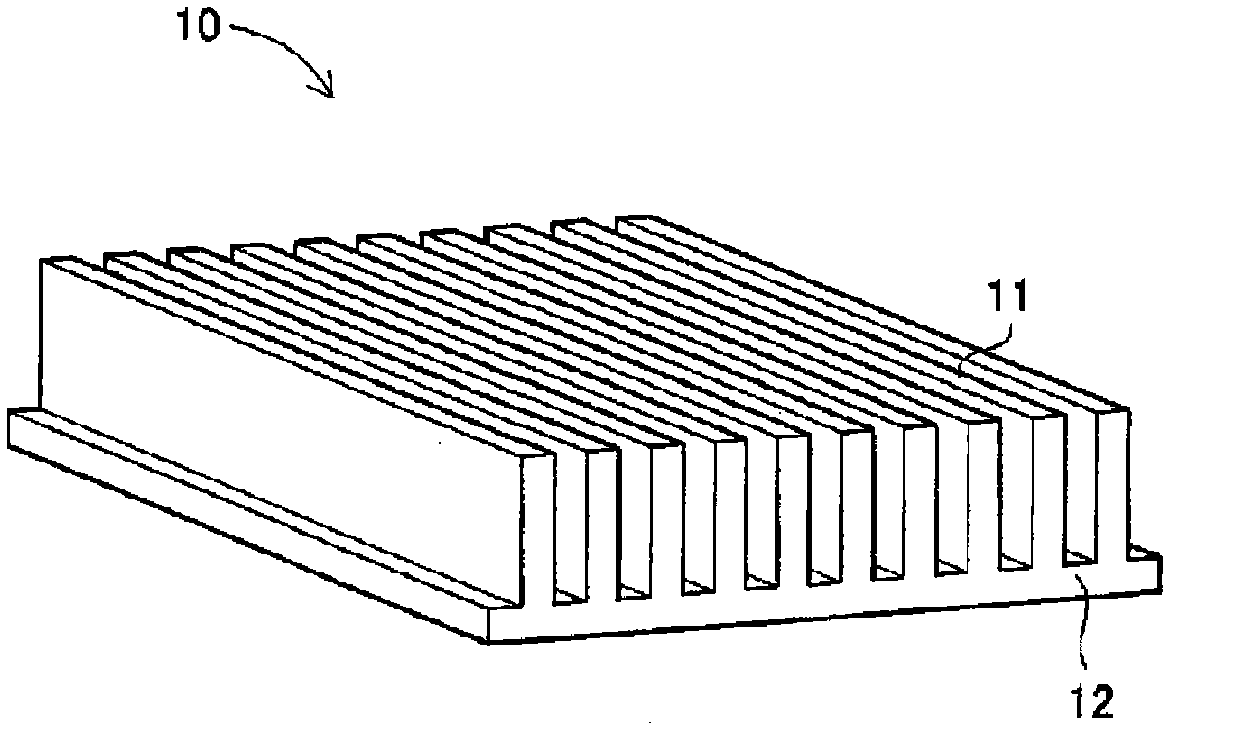

[0056] In this heat exchanger 1 , a plurality of fins 11 are arranged in a cylindrical body 2 to form a plurality of flow paths 3 communicating from an inlet opening 21 of the body 2 to an opposite outlet opening. The main body 2 of the heat exchanger 1 allows coolant to flow in, for example, a direction indicated by an arrow Q, and communicates from the inflow-side opening 21 to the opposite discharge-side opening.

[0057] in addition, figure 1 shows the heat exchanger 1 in which the inflow-side opening 21 and the discharge-side opening on the opposite side are largely opened on the main body 2, but in use, they are respectively closed and supplied with coolant not shown in the figure. pipe or coolant drain connection. Also, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com