Time synchronization in industrial process control or automation systems

A technology for industrial process control and automation systems, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as failure of protection algorithms, achieve the effect of increasing availability and avoiding interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

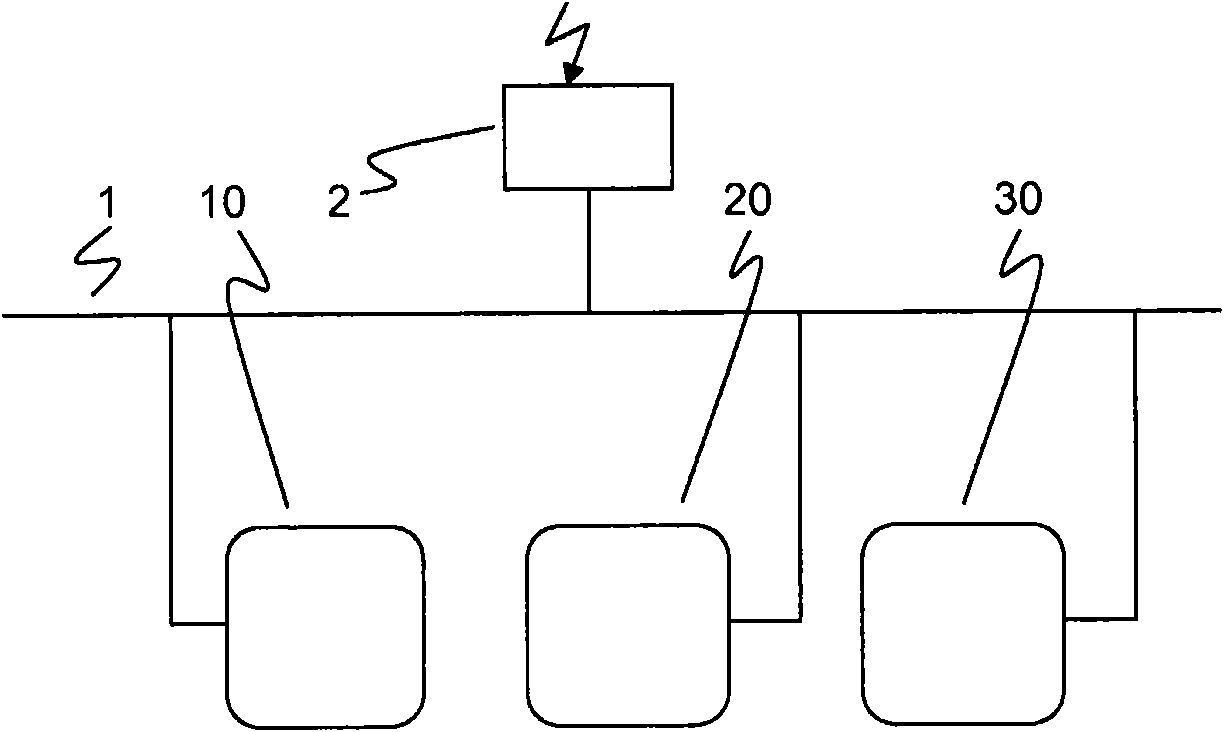

[0022] figure 1An excerpt of a Substation Automation (SA) system showing a substation of a power transmission system as an example of an industrial process control or automation system. The SA system comprises a communication network 1, i.e. a station bus or process bus extending beyond a single bay, and three Intelligent Electronic Devices (IEDs) as exemplary network devices performing protection and control functions on behalf of the bays of the substation (not shown) Or spacer units 10, 20, 30. The master clock device 2 or GPS receiver provides the system reference time to the IEDs eg via an Ethernet based protocol eg IEEE1588 and thus ensures time synchronization of the protection and control functions configured on the IEDs.

[0023] In the context of the present invention, two different configurations are considered: (a) a normal configuration in which GPS signals are received and propagated to the SA system; and (b) a failure configuration in which either the GPS signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com