Optimization method for carbon nanotube and metal copper composite electroplating process

A carbon nanotube and composite electroplating technology, applied in the micro-nano field, can solve problems such as process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

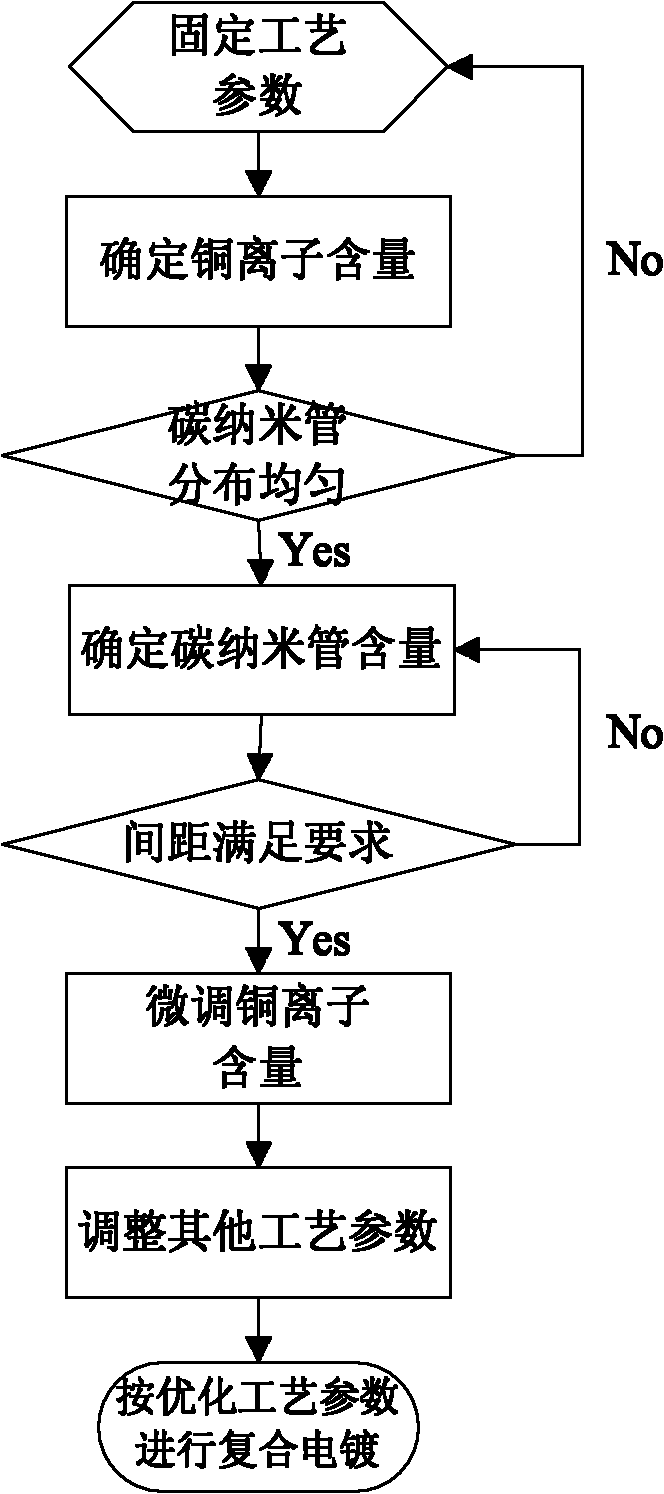

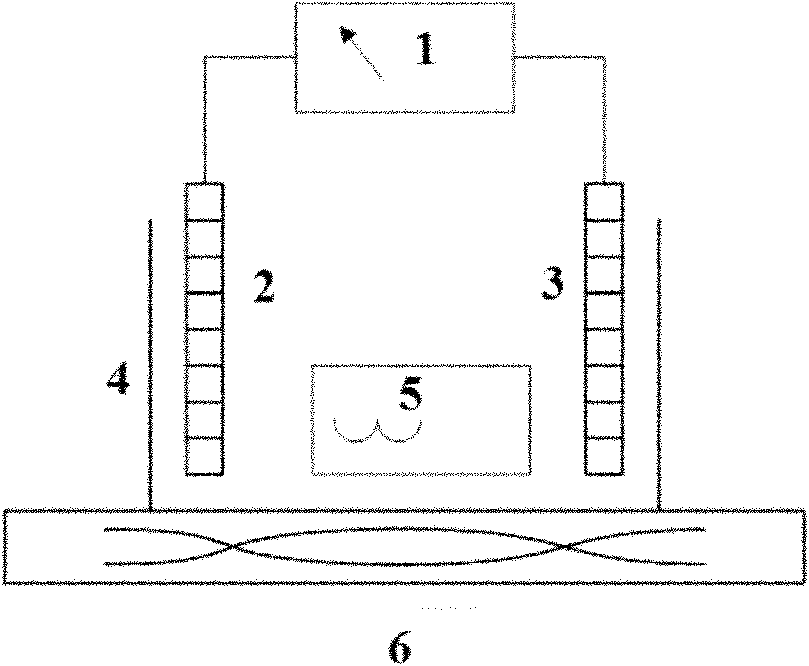

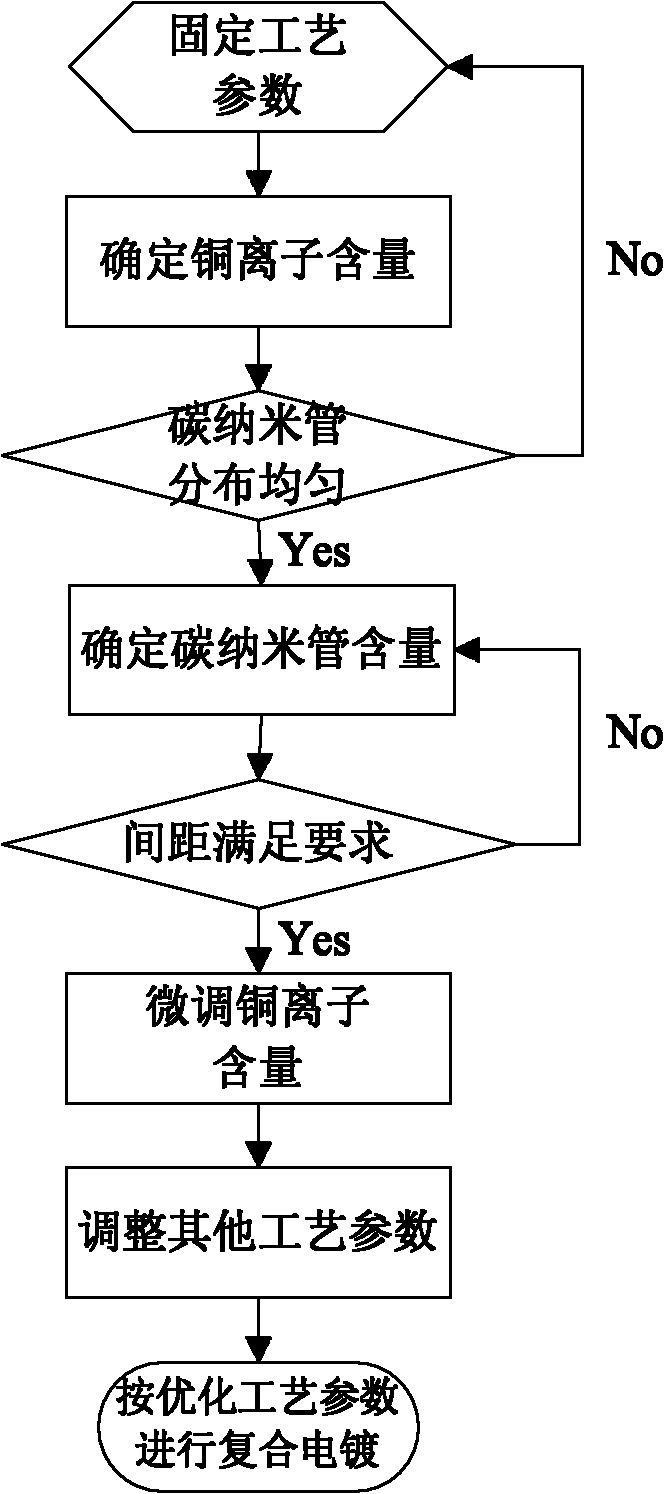

[0032] Such as figure 1 As shown, the present embodiment performs electroplating in the following manner:

[0033] 1) Select the copper ion concentration as the optimization parameter, the initial copper sulfate content is 200g / L, and add carbon nanotubes 1g / L, sulfuric acid 30ml / L, polyacrylic acid 2g / L, hydrochloric acid 1ml / L, brightener 207C agent 4ml / L, A agent 0.4ml / L;

[0034] 2) The auxiliary process of electroplating adopts ultrasonic intermittent oscillation, the working time and pause time of the ultrasonic oscillator are kept at 2:1, and the frequency is 200W; other process parameters are: current density 3A / dm 2 , the distance between cathode and anode is 15cm;

[0035] 3) Use a thermometer to monitor the temperature in the bath, and the temperature range is 25-30°C. If the temperature fluctuates, add cold water to the water bath to adjust the temperature;

[0036] 4) An ammeter connected in series in the circuit monitors the current intensity of the cathode a...

Embodiment 2

[0040] 1) Select the carbon nanotube content as the optimization parameter, the initial carbon nanotube 1g / L, and add the content of copper sulfate 140g / L, sulfuric acid 30ml / L, polyacrylic acid 2g / L, hydrochloric acid 1ml / L, brightener 207C agent 4ml / L, A agent 0.4ml / L;

[0041] 2) The auxiliary process of electroplating adopts ultrasonic intermittent oscillation, the working time and pause time of the ultrasonic oscillator are kept at 2:1, and the frequency is 200W; other process parameters are: current density 3A / dm 2 , the distance between cathode and anode is 15cm;

[0042] 3) Use a thermometer to monitor the temperature in the bath, and the temperature range is 25-30°C. If the temperature fluctuates, add cold water to the water bath to adjust the temperature;

[0043] 4) An ammeter connected in series in the circuit monitors the current intensity of the cathode and anode, and maintains the current density of the cathode and anode;

[0044] 5) Increase the content of c...

Embodiment 3

[0047] 1) Select polyacrylic acid as the optimization parameter, initial polyacrylic acid 2g / L, carbon nanotube 5g / L, and add copper sulfate content 135g / L, sulfuric acid 30ml / L, hydrochloric acid 1ml / L, brightener 207C agent 4ml / L, A agent 0.4ml / L;

[0048] 2) The auxiliary process of electroplating adopts ultrasonic intermittent oscillation, the working time and pause time of the ultrasonic oscillator are kept at 2:1, and the frequency is 200W; other process parameters are: current density 3A / dm 2 , the distance between cathode and anode is 15cm;

[0049] 3) Use a thermometer to monitor the temperature in the bath, and the temperature range is 25-30°C. If the temperature fluctuates, add cold water to the water bath to adjust the temperature;

[0050] 4) An ammeter connected in series in the circuit monitors the current intensity of the cathode and anode, and maintains the current density of the cathode and anode;

[0051] 5) Increase the content of polyacrylic acid and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com