Preparation method and device of dual different-shrinkage combined filament yarn

A technology of different shrinkage mixed filament yarn and preparation device, which is applied in the field of synthetic fiber manufacturing, can solve the problems of thin and rigid cloth surface, uneven coils, large difference in component shrinkage rate, etc., and achieve the effect of rich layering and fluffy appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

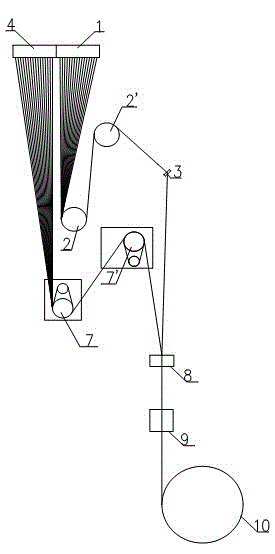

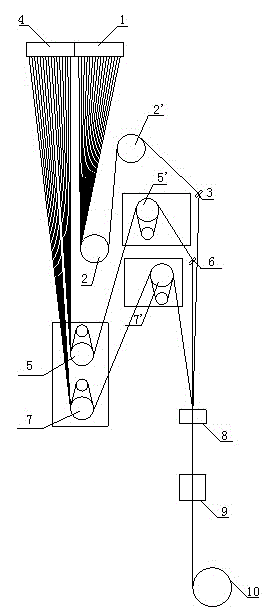

[0022] Preparation device of double different shrinkage mixed filament:

[0023] Such as figure 2 As shown, it is a schematic diagram of the structure of the device for preparing double different shrinkage mixed filaments. The preparing device for double different shrinkage mixed filaments consists of a first spinning assembly 1, a second spinning assembly 4, a lower guide plate 2, and an upper Godet 2', first heat roller 7, second heat roller 7', first diverter 3, third heat roller 5, fourth heat roller 5', second diverter 6, doubling device 8, network The yarn spun from the first spinning assembly 1 passes through the lower godet 2, the upper godet 2', and the first diverter 3, and then enters the yarn doubling device 8. A part of the filaments spun by the component 4 passes through the first heat roller 7 and the second heat roller 7'in turn, and then enters the yarn doubling device 8. The other part of the filaments spun by the second spinning assembly 4 passes through the ...

Embodiment 2

[0025] Preparation of polypropylene double different shrinkage mixed filament:

[0026] Raw material: polypropylene chips (melt index is 36g / 10 min, melting point is 170℃);

[0027] Equipment: the same as the preparation device of double different shrinkage mixed filament described in Example 1;

[0028] Preparation method: After the polypropylene melt is ejected through the first spinning assembly 1, it passes through the lower godet 2 with a speed of 3500m / min, the upper godet 2'with a speed of 3500m / min and the first diverter 3 , Form pre-oriented yarn, boiling water shrinkage rate is 55%. After the polypropylene melt is ejected from the second spinning assembly 4, it is divided into two filaments: one filament passes through the first heat roller 7 with a temperature of 60°C and a speed of 1000m / min and a temperature of 60°C and a speed in turn. The second hot roller 7'with a temperature of 3500m / min forms the first fully drawn yarn; another bundle of filaments passes through t...

Embodiment 3

[0030] Preparation of polyamide 66 double different shrinkage mixed filament yarn:

[0031] Raw material: polyamide 66 chips (relative viscosity 52, melting point 250°C);

[0032] Equipment: the same as the preparation device of double different shrinkage mixed filament described in Example 1;

[0033] Preparation method: After the polyamide 66 melt is ejected through the first spinning assembly 1, it passes through the lower godet 2 with a speed of 4200m / min, the upper godet 2'and the first diverter 3 with a speed of 4200m / min, The pre-oriented yarn is formed, and the boiling water shrinkage rate is 60%. After the polyamide 66 melt is ejected through the second spinning assembly 4, it is divided into two filaments: one filament passes through the first heat roller 7 with a temperature of 80°C and a speed of 1000m / min and a temperature of 60°C. The second heat roller 7'with a speed of 4200m / min forms the first fully drawn filament; another bundle of filaments sequentially passes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com