A one-step production process of high-strength and high-shrinkage mixed fiber yarn

A production process, high shrinkage technology, applied in the directions of melt spinning, fiber processing, filament/thread forming, etc., can solve problems such as low elasticity, and achieve the effect of plump fabric, three-dimensional effect, and large controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

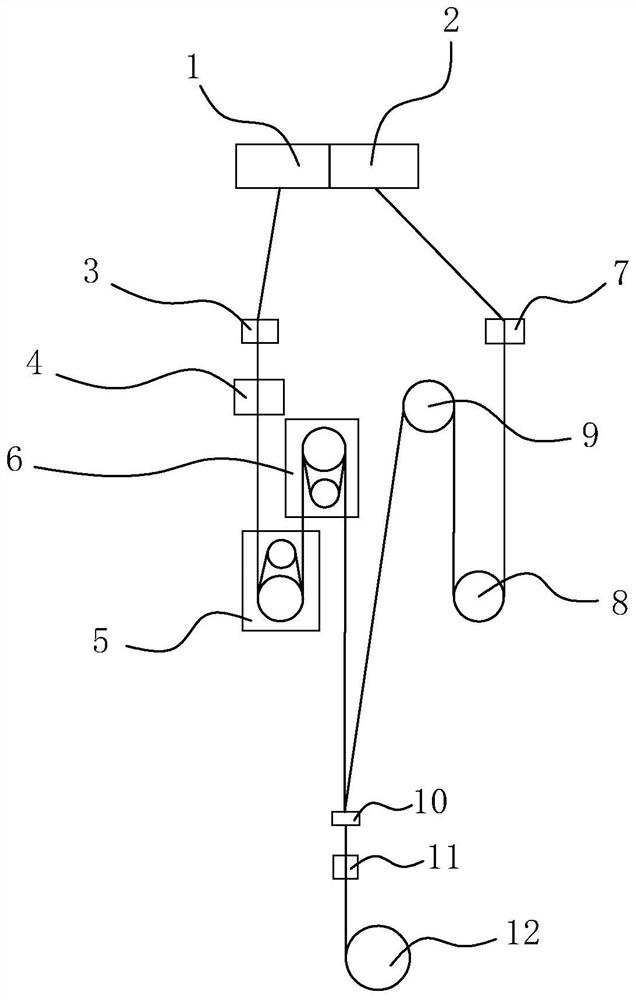

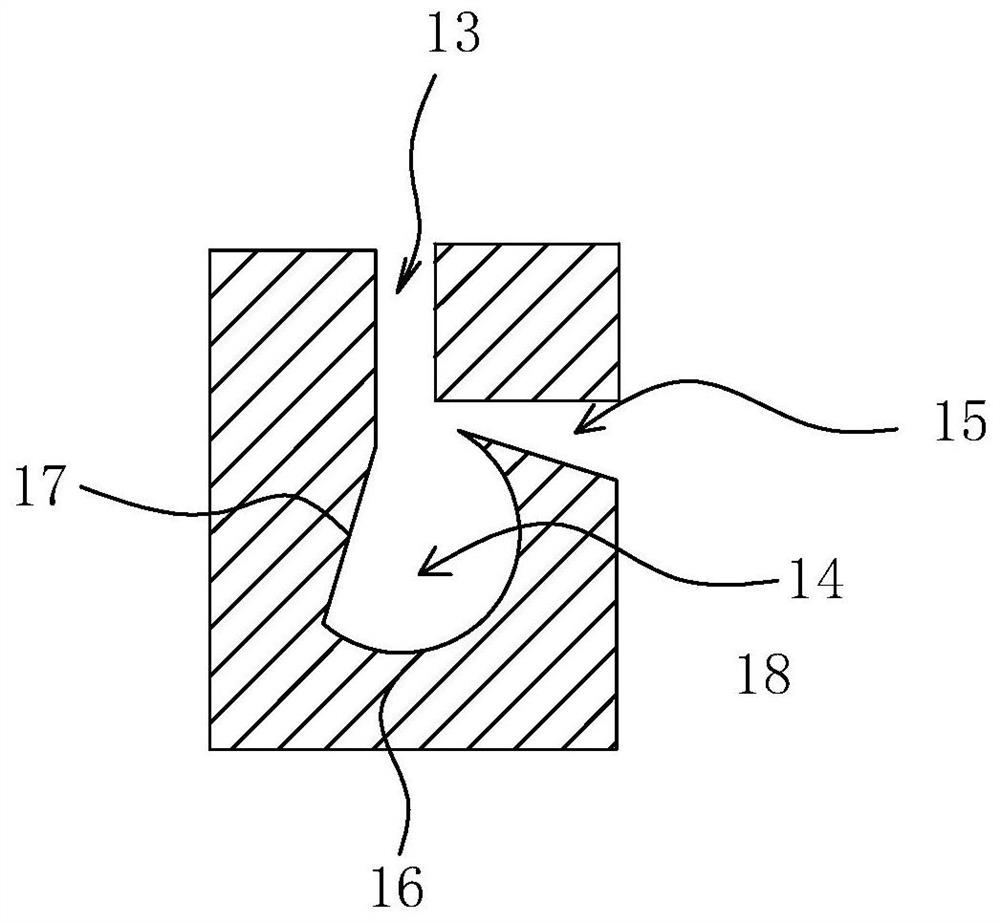

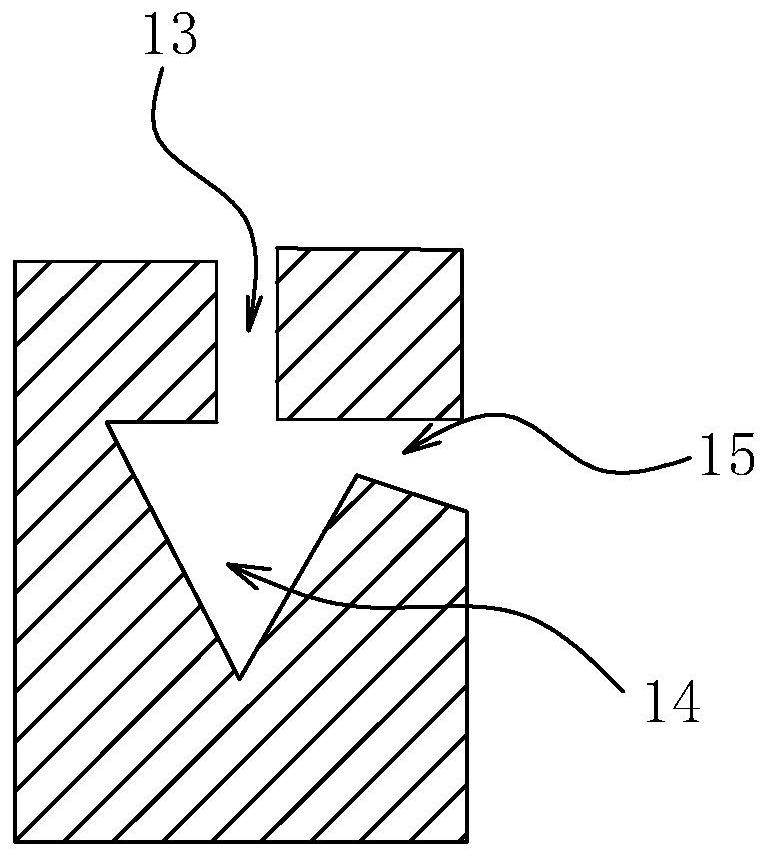

[0029] combine Figure 1 to Figure 2 , to describe this embodiment in detail. The one-step production process of high-strength and high-shrinkage mixed fiber yarn involved in this embodiment includes the following steps: S1 slice drying, S2 spinning of high-strength polyester filament part, S3 spinning of high-elastic polyester filament part, S4 high-strength polyester filament and high-elastic polyester filament are connected to the grid, and S5 is wound.

[0030] In step S1 slice drying, the high-shrinkage copolyester slices are dried with hot air in a hot-air drying device, so that the moisture content of the high-shrinkage copolyester slices is ≦25×10 -6 , fluctuation value≦5×10 -6 ;The dew point of the drying air≦-35℃, the air inlet pressure of the drying tower≧7MPa, the air outlet air pressure≧8MPa, and the pressure difference between the inlet and outlet air pressure is maintained at about 1MPa; the high-shrinkage copolyester chip component is purified p-phenylene Co...

Embodiment 2

[0050] to combine Figure 1 to Figure 2 , to describe this embodiment in detail. The one-step production process of high-strength and high-shrinkage mixed fiber yarn involved in this embodiment includes the following steps: S1 slice drying, S2 spinning of high-strength polyester filament part, S3 spinning of high-elastic polyester filament part, S4 high-strength polyester filament and high-elastic polyester filament are connected to the grid, and S5 is wound.

[0051] In step S1 slice drying, the high-shrinkage copolyester slices are dried with hot air in a hot-air drying device, so that the moisture content of the high-shrinkage copolyester slices is ≦25×10 -6 , fluctuation value≦5×10 -6 ;The dew point of the drying air≦-35℃, the air inlet pressure of the drying tower≧7MPa, the air outlet air pressure≧8MPa, and the pressure difference between the inlet and outlet air pressure is maintained at about 1MPa; the high-shrinkage copolyester chip component is purified p-phenylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com