Underneath-camshaft low-noise engine and motorcycle using same

An engine, low-noise technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problem that the noise of the cylinder head of the rocker arm mounting seat cannot be fundamentally restrained, the setting position has not been judged and calculated, and the rocker arm The problem of large thermal deformation of the mounting seat can increase the rigidity, reduce the interference friction, and avoid thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

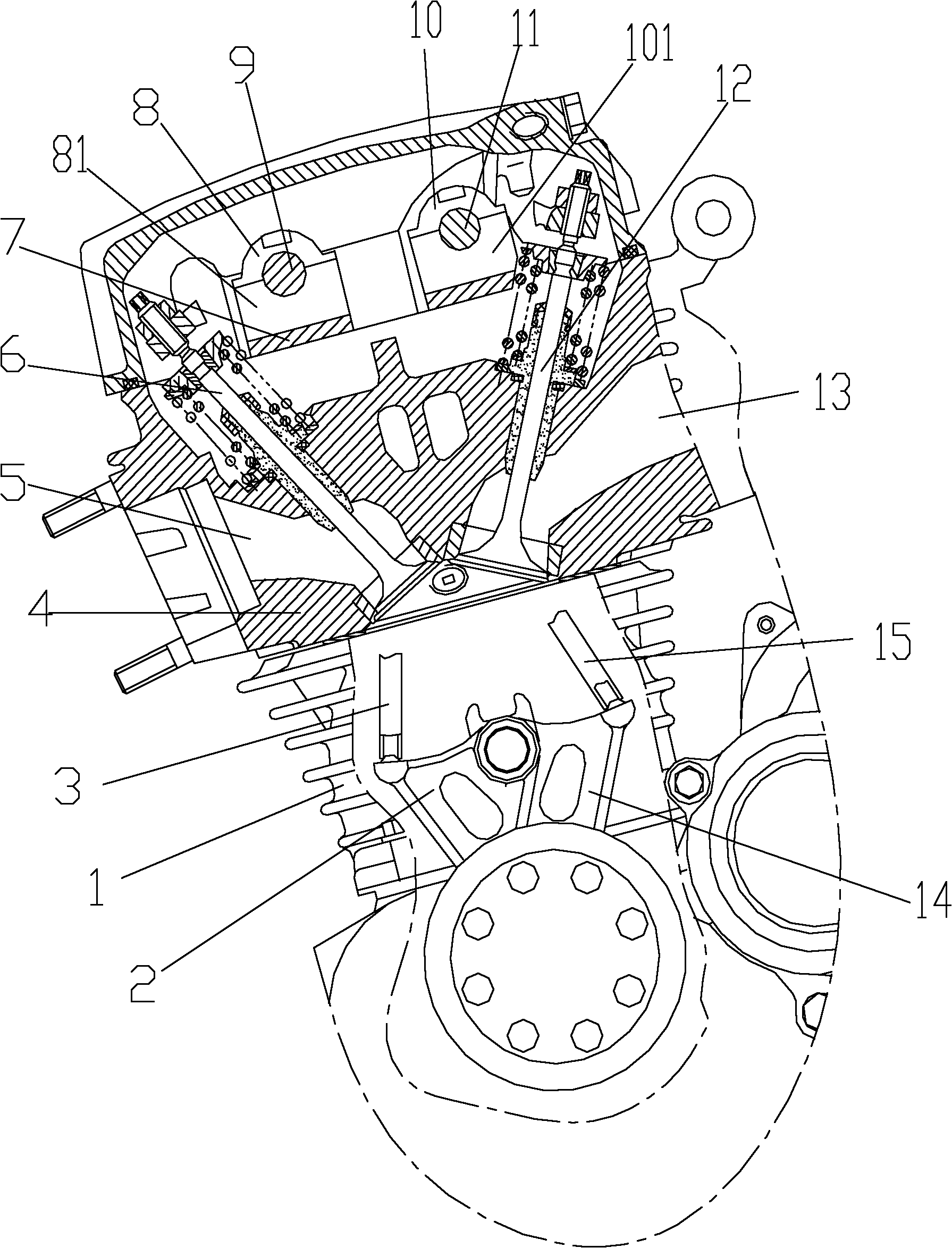

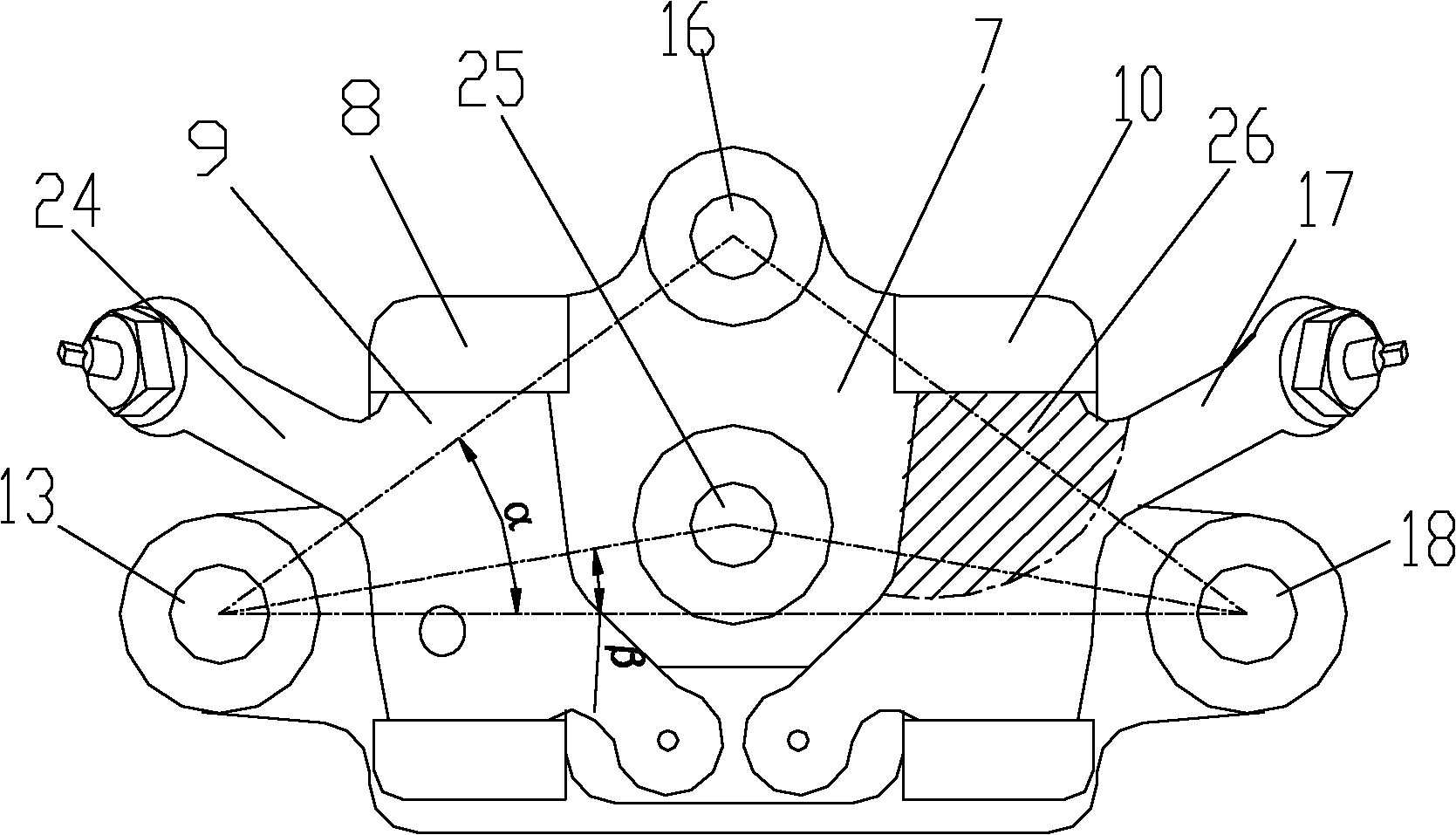

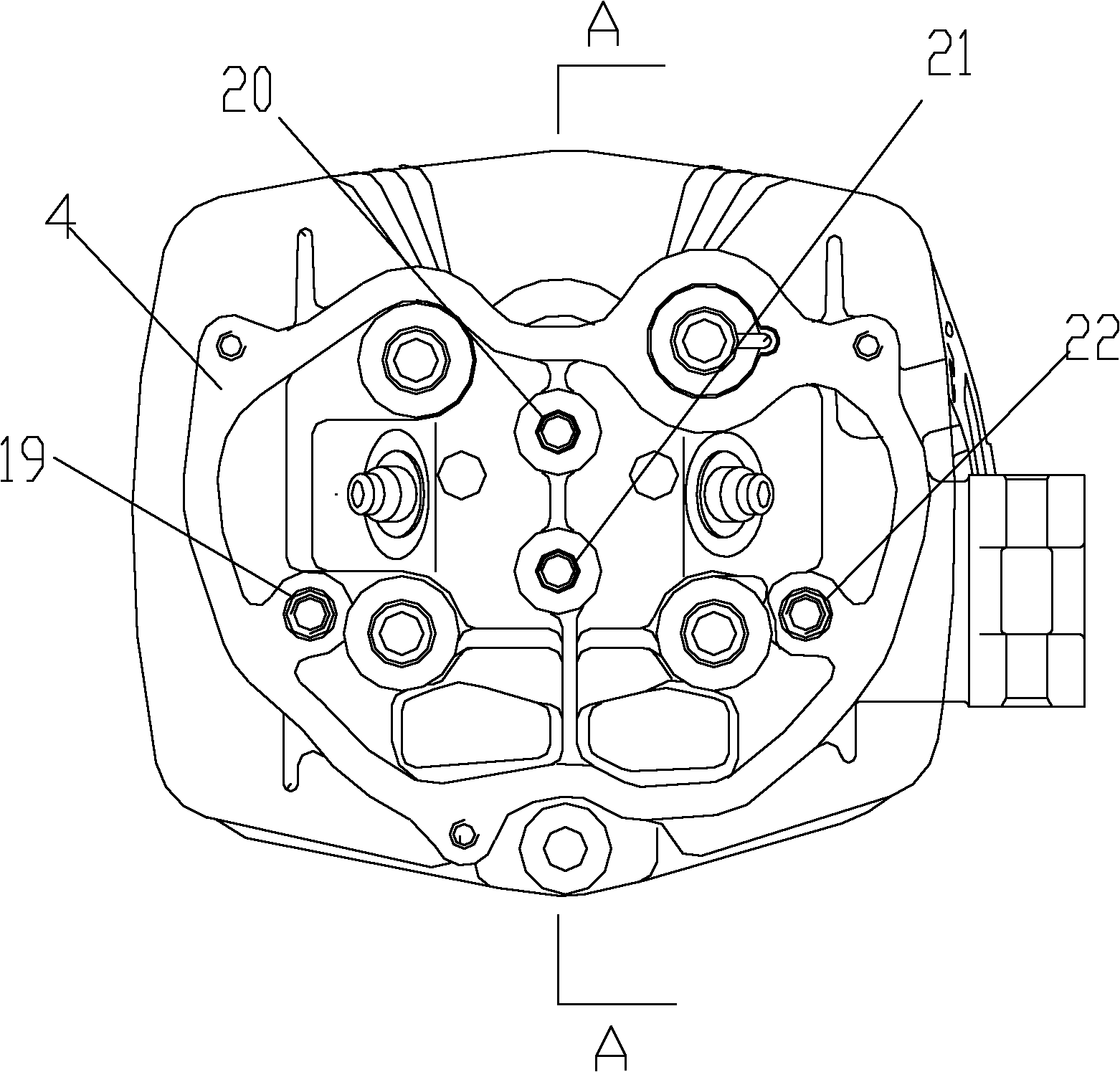

[0030] figure 1 It is a structural schematic diagram of the present invention, figure 2 is the plan view of the rocker arm mount, image 3 is the plan view of the cylinder head for mounting the rocker arm mount, Figure 4 for image 3 Sectional view along A-A direction, Figure 5 It is the sectional view of the cooperation between the rocker shaft and the rocker seat (the exhaust valve rocker is taken as an example), Image 6 for Figure 5 Sectional view along B-B direction, Figure 7It is a schematic diagram of the lower rocker arm structure, as shown in the figure: the low-noise engine with a lower camshaft in this embodiment includes a cylinder block 1, a cylinder head body 4 and a rocker arm assembly arranged on the cylinder head body 1. The arm assembly includes a rocker arm mounting seat 7 and an intake valve rocker arm seat and an exhaust valve rocker arm seat fixedly arranged on the rocker arm mounting seat 7. The rocker arm mounting seat 7 is fixedly arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com