High-pressure gear pump with intermediate-pressure bearing lubrication

A bearing lubrication and gear pump technology, applied in the field of hydraulic machinery, can solve the problems of reduced service life of bearings, increase of temperature of sliding bearings, large outlet pressure difference, etc., and achieve sufficient oil supply, improved service life and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

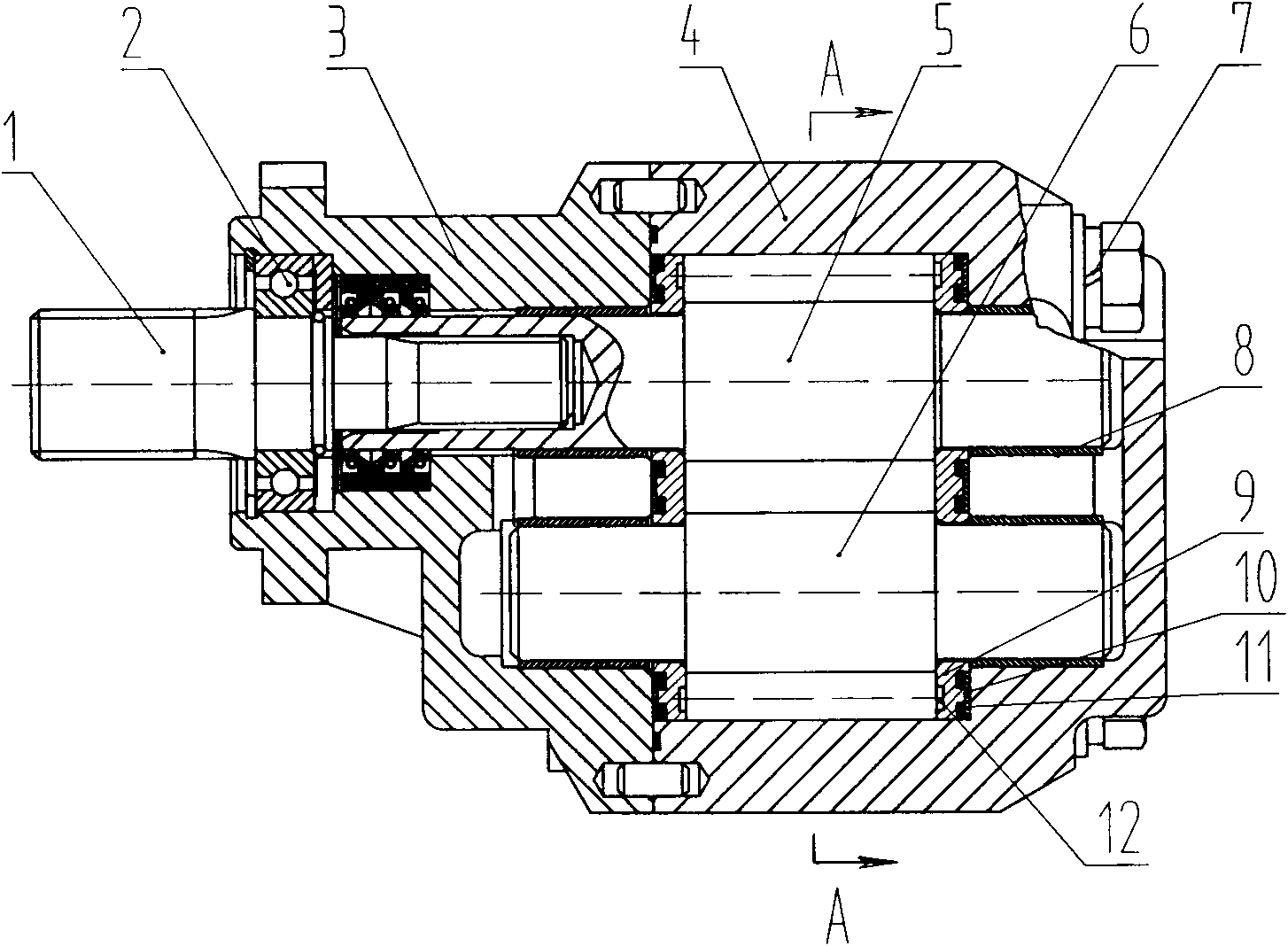

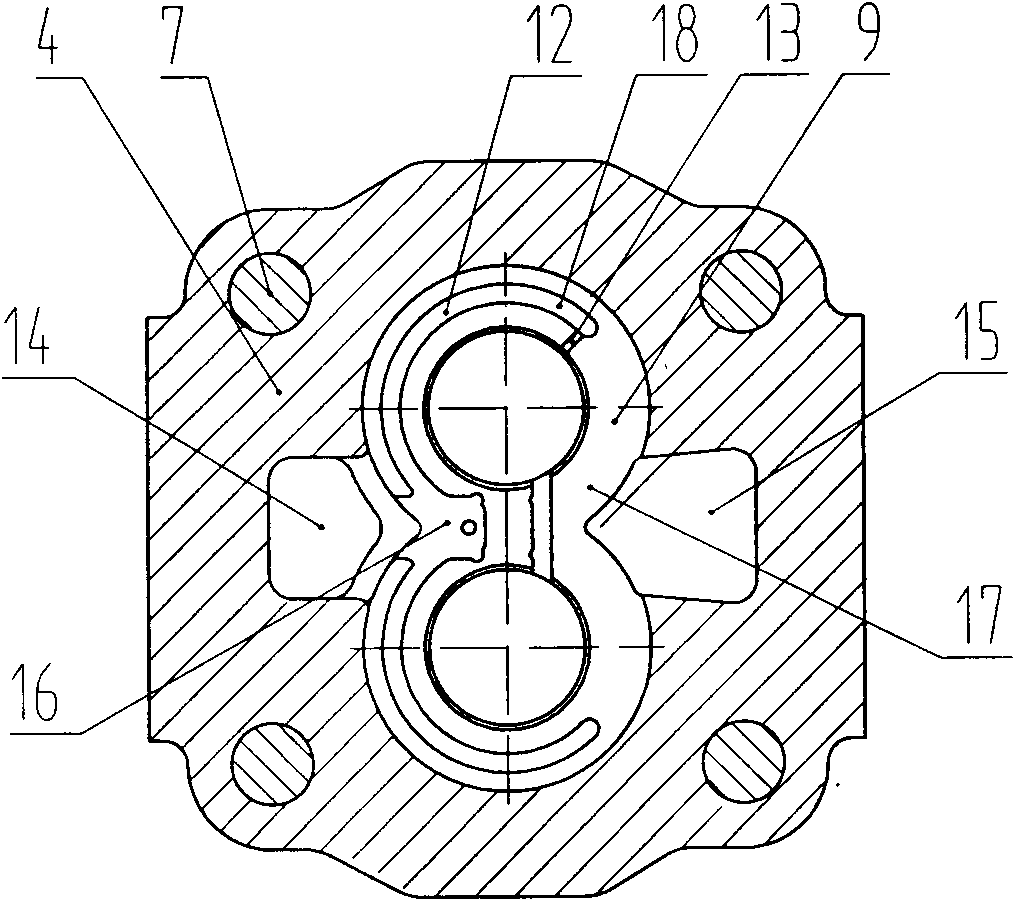

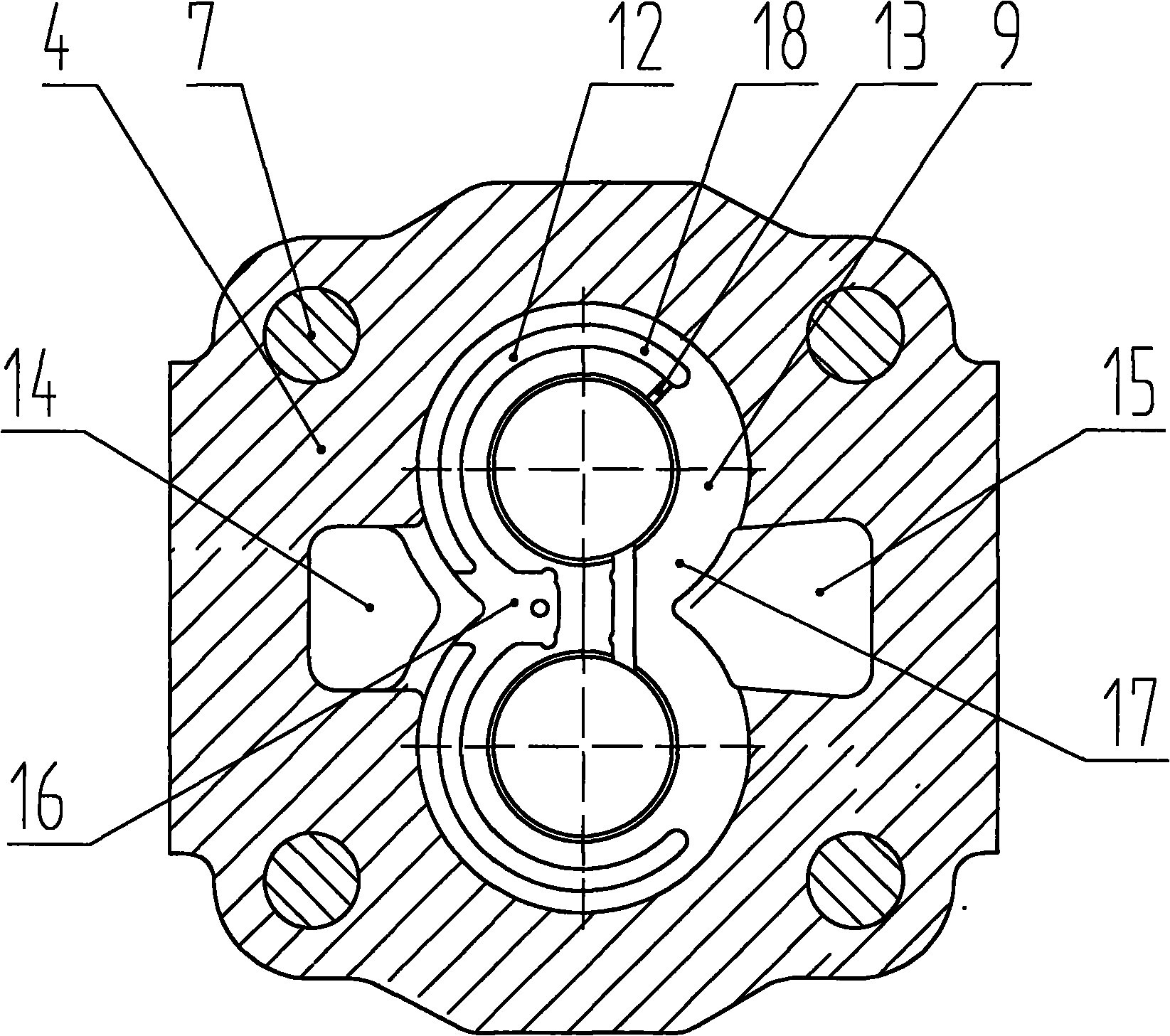

[0015] Such as figure 1 , figure 2 Shown: a high-pressure gear pump with secondary high-pressure bearing lubrication. The gear pump adopts a two-piece structure, namely, driving gear 5, driven gear 6, two floating side plates 9, two W-shaped sealing rings (11 ) And the support plate (10) are installed in the inner cavity of the pump body 4. The pump body 4 and the pump cover 3 are connected by bolts 7 and locating pins to form a single or double or multiple gear pump; the driving gear 5 and the slave The gear shafts of the movable gear 6 are respectively mounted on the pump body 4 and the pump cover 3 through sliding bearings 8; the driving gear 5 is connected to the power source through the coupling shaft 1, and the coupling shaft 1 is mounted on the pump cover 3 through the bearings 2; The pump body 4 has an oil outlet 14 and an oil inlet 15; the connection between the oil outlet 14 and the pump body 4 is a high pressure zone 16, and the connection between the oil inlet 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com