III-nitride compound semiconductor element and manufacturing method thereof

A manufacturing method and nitride technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problem of peeling off the insulating protective film, inability to effectively protect the semiconductor element, and poor adhesion between the metal layer and the insulating protective film and other problems, to achieve the effect of improving reliability, high tightness, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

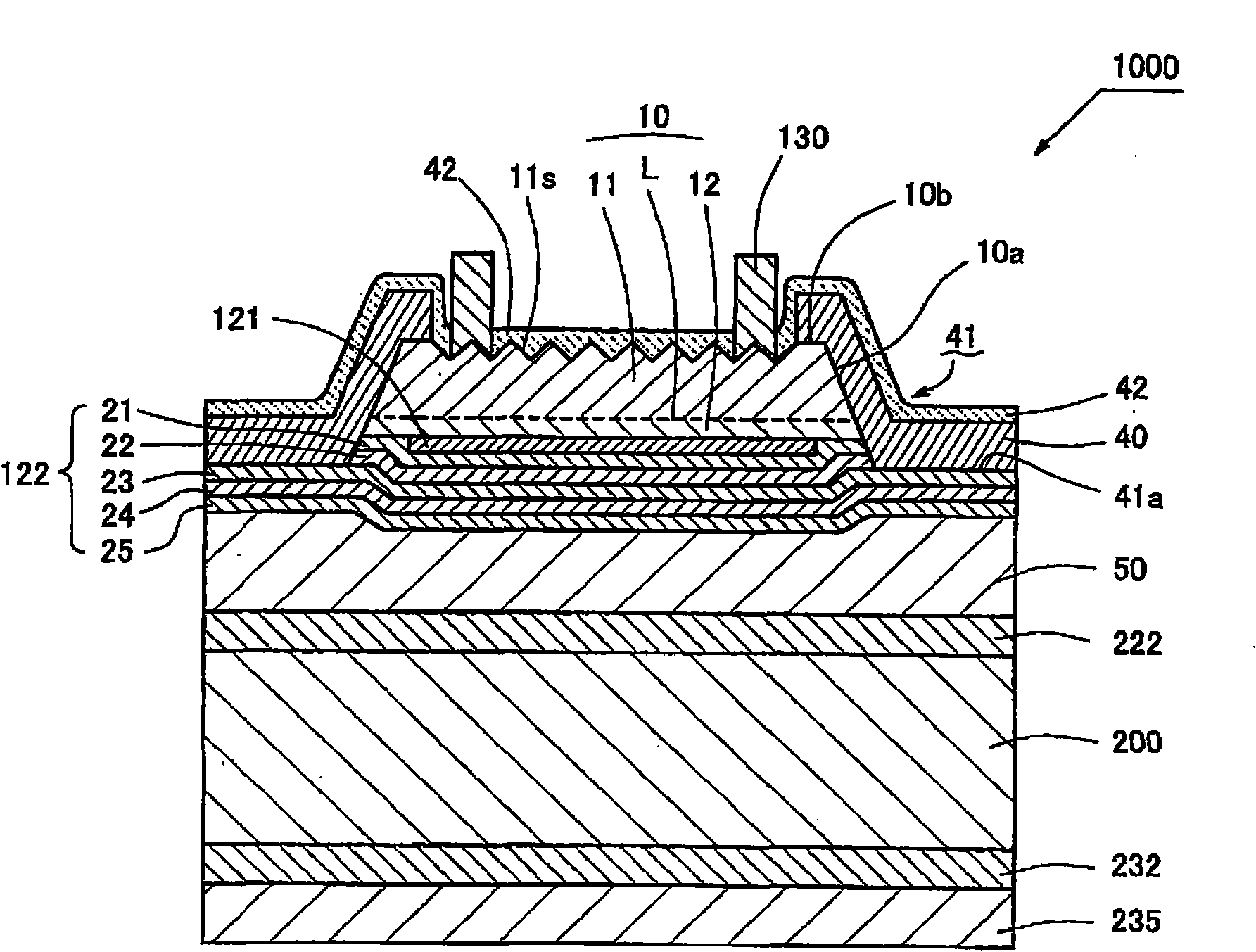

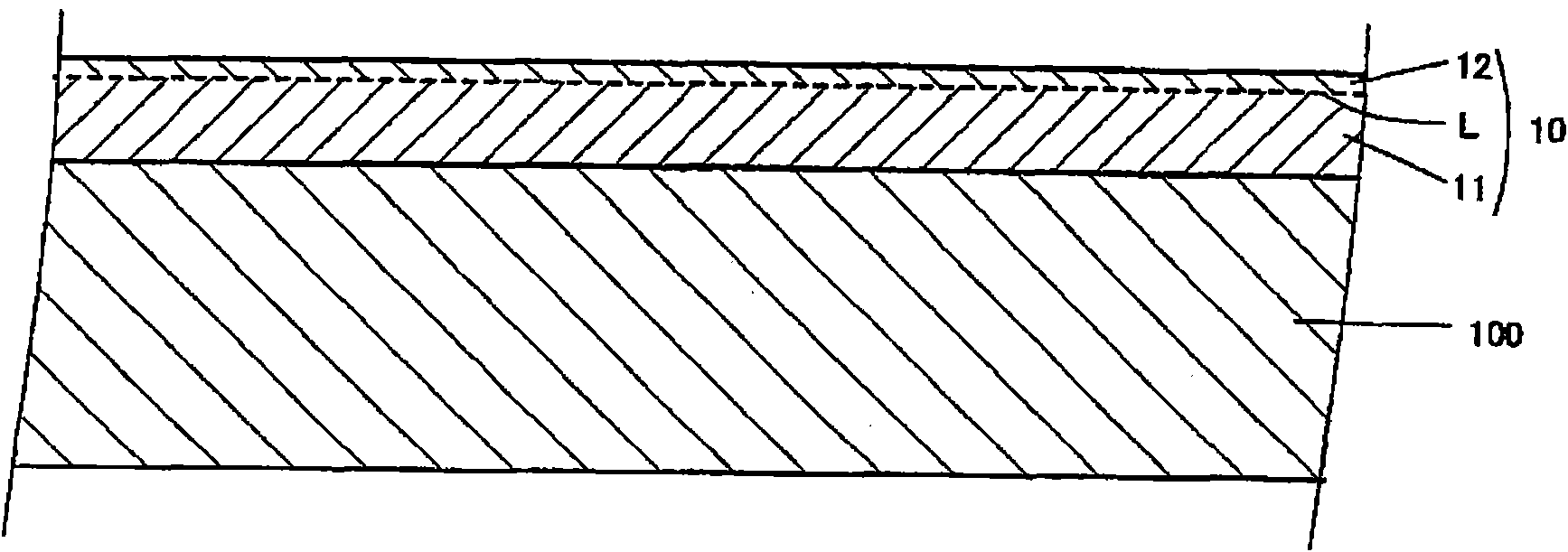

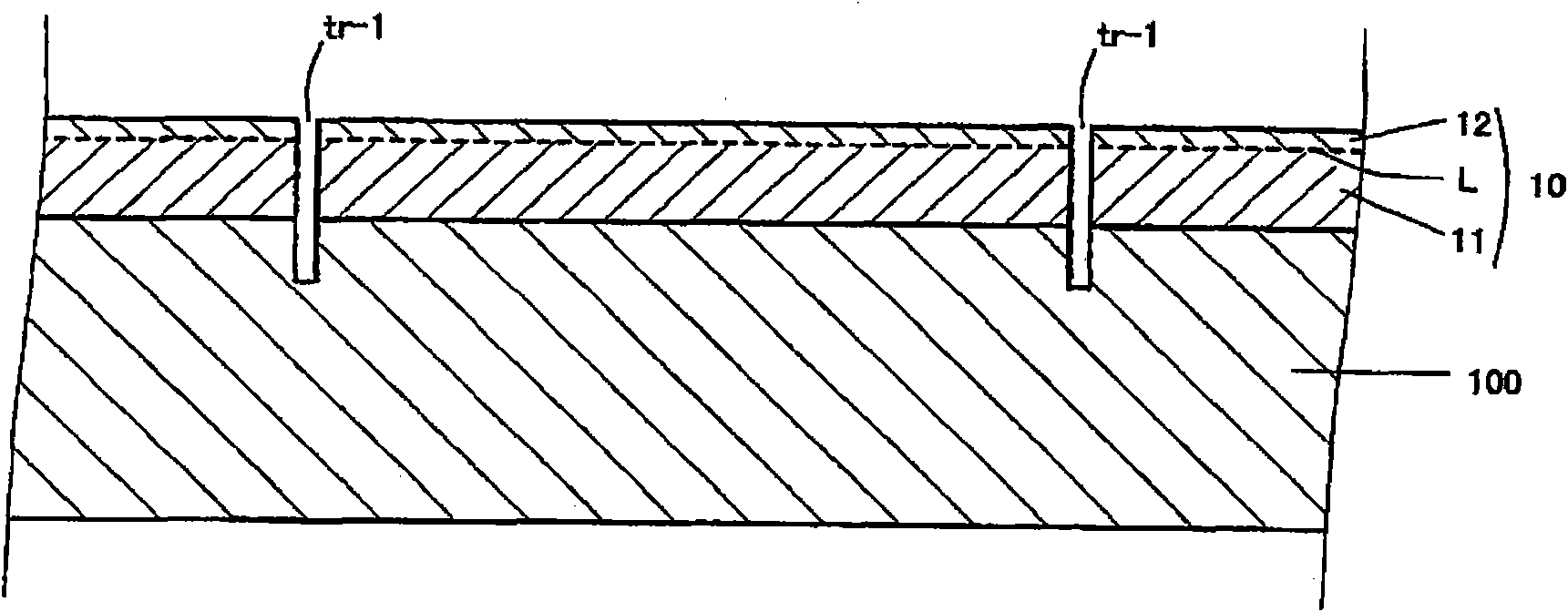

[0039] figure 1 is a cross-sectional view showing the structure of a III-nitride compound semiconductor element (blue LED) 1000 obtained by a manufacturing method according to a specific example of the present invention. figure 1 The III-nitride compound semiconductor device (blue LED) 1000 has the following stacked structure: on the surface of the p-type silicon substrate, that is, the conductive support substrate 200, multiple metals are laminated from the side closer to the support substrate 200. The second conductive layer 222 composed of laminated layers, the solder layer (solder layer) 50 as a low melting point alloy layer, the first conductive layer 122 composed of laminated layers of various metals, the p-contact electrode 121, mainly p-type a single-layer or multi-layer p-type layer 12 of a Group III nitride compound semiconductor layer, a light-emitting layer L, a single-layer or multi-layer n-type layer 11 of a mainly n-type Group III nitride compound semiconductor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com