Method for preparing slurry for catalyst coating membrane electrode of proton exchange membrane fuel cell

A catalyst coating and proton exchange membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of uneven catalyst loading and poor electrode slurry stability, and achieve uniform and stable discharge performance. High discharge performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

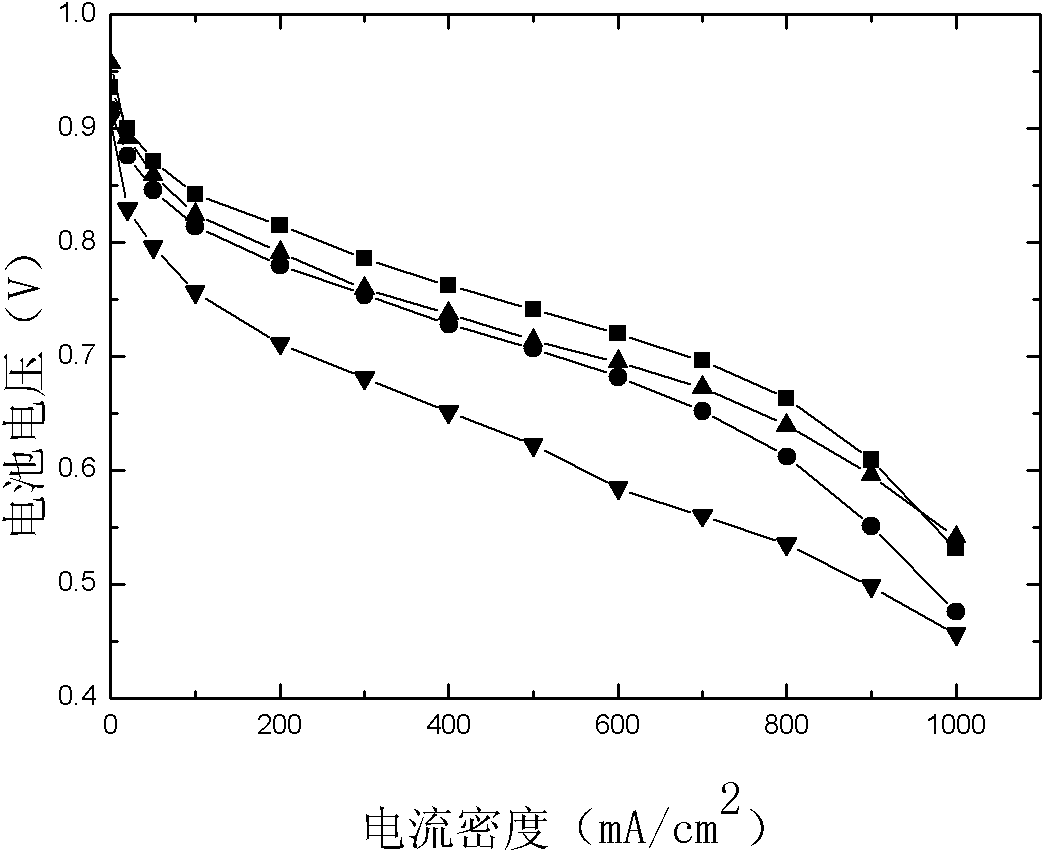

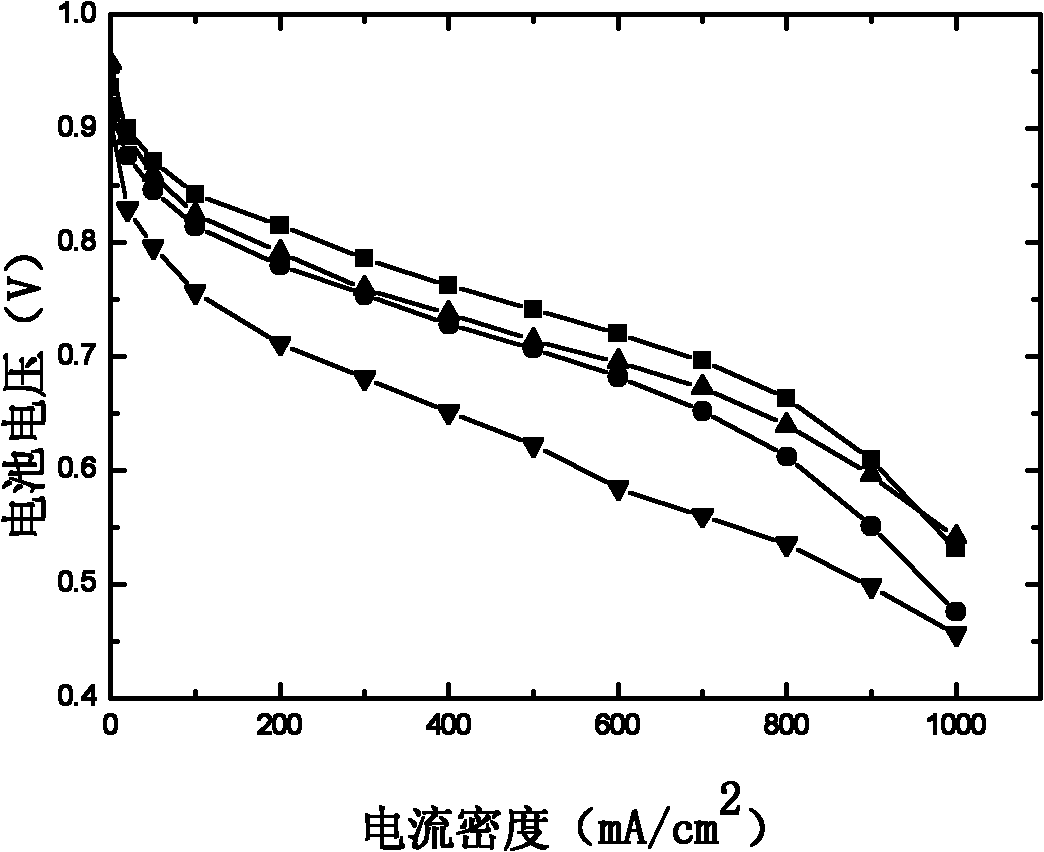

Image

Examples

Embodiment 1

[0015] 1) Weigh 2g of 50%wt.Pt / C catalyst, 80g of deionized water, 60g of isopropanol, 18g of 5% Nafion solution, and 0.5g of ethylene glycol solution in a 250ml screw bottle.

[0016] 2) Disperse the catalyst material with a disperser. The speed of the disperser is controlled at 25,000 rpm, and the dispersion time is 60 minutes. At the same time, circulating water is used to cool the electrode slurry to ensure that the temperature of the electrode slurry does not rise under high-speed stirring.

[0017] 3) Place the dispersed electrode slurry in a water bath at 60°C for concentration, and at the same time stir with an electric stirrer to ensure that the solvent in the slurry is evenly volatilized. Stop concentrating when the quality of slurry is reduced to 125.625g.

[0018] 4) Place the concentrated electrode slurry in an autoclave, set the temperature of the autoclave to 80° C., adjust the pressure to 6 MPa and keep the pressure constant for 10 hours, then release the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com