Adsorption system for carbon dioxide

An adsorption system, carbon dioxide technology, applied in the direction of adsorption, inorganic chemistry, silicon compounds, etc., can solve the problems of non-moisture content, not easy to deteriorate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

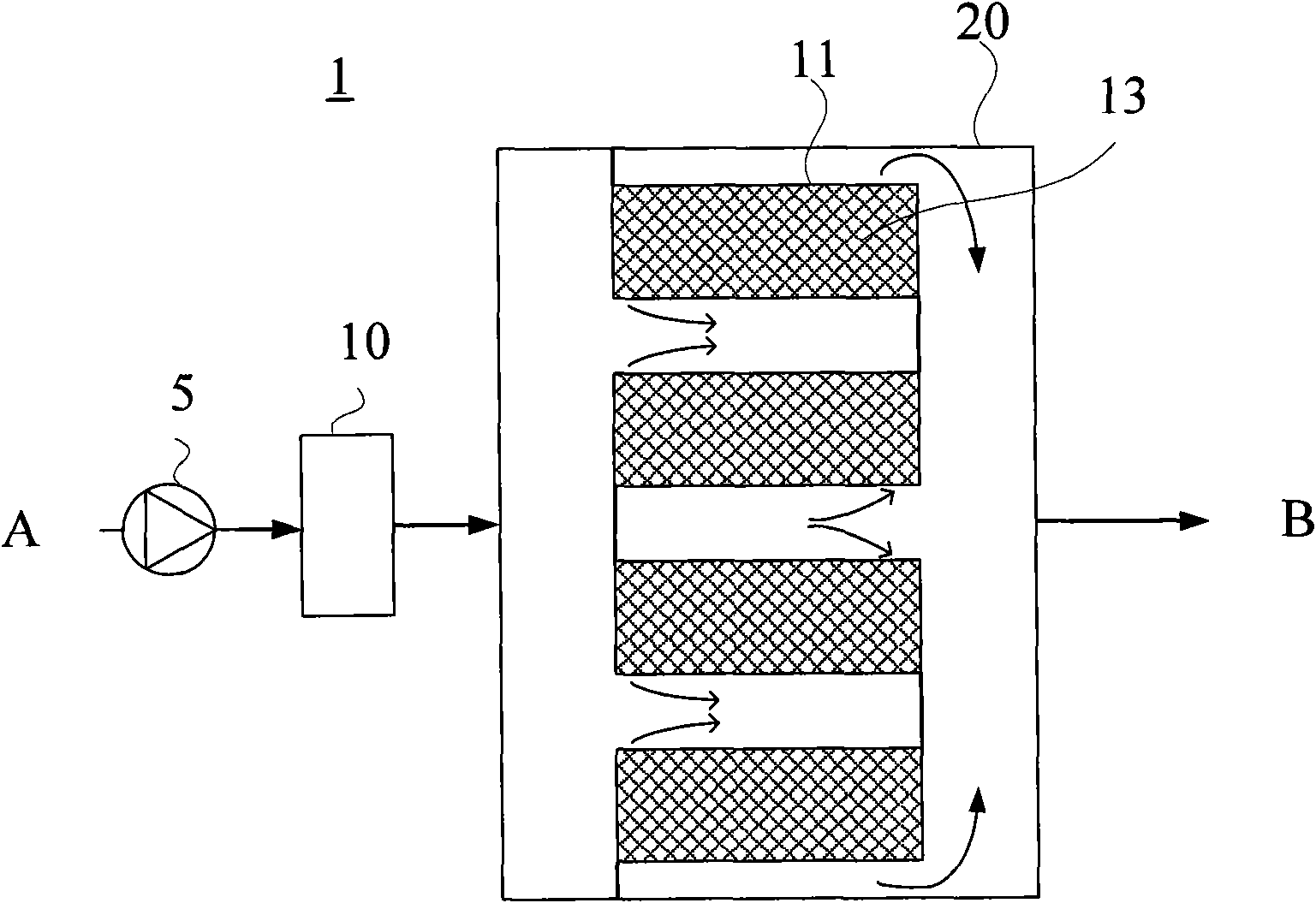

[0045] A carbon dioxide adsorption system 1 according to the first specific embodiment of the present invention is as follows: figure 2As shown, the system includes: a humidity conditioner 10 and an adsorption device 20 ; wherein the adsorption device 20 includes a plurality of carbon dioxide adsorption units 11 , and the carbon dioxide adsorption units 11 are filled with carbon dioxide adsorption materials 13 .

[0046] When the carbon dioxide adsorption system 1 performs carbon dioxide adsorption and purification, the waste gas to be treated is blown into the carbon dioxide adsorption system 1 from a gas inlet A through a windmill 5, and first flows through the humidity conditioner 10. The humidifier 10 is a water spray humidifier with both humidification and cooling functions to adjust the humidity of the waste gas to be treated, and then the humidified waste gas to be treated enters the adsorption device 20, and as figure 2 The arrows in the adsorption device 10 carry ou...

Embodiment 2

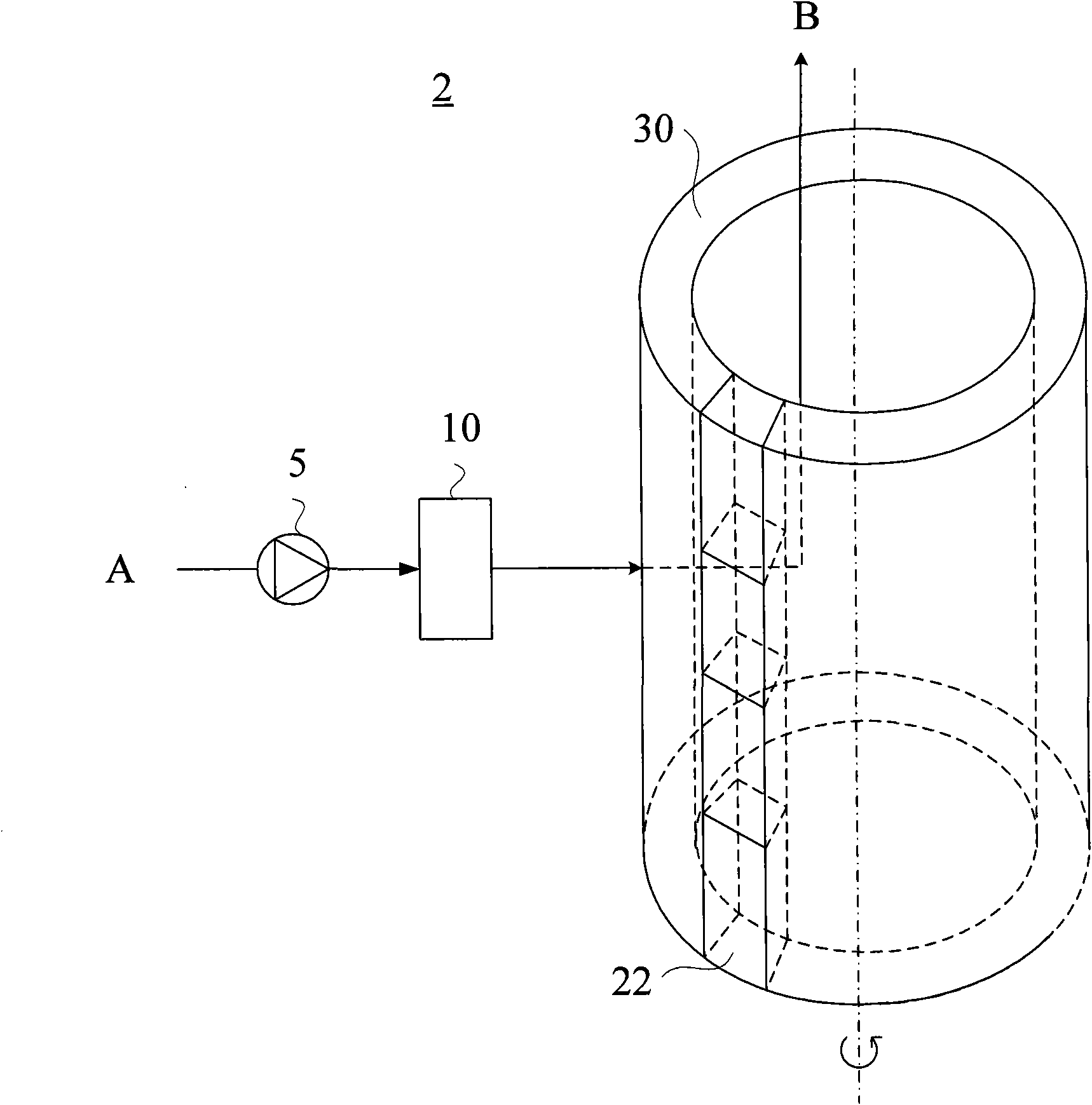

[0048] A carbon dioxide adsorption system 2 according to the second specific embodiment of the present invention is as follows: image 3 As shown, the system includes: a humidity conditioner 10 and a rotating swivel adsorber 30; wherein the rotating swivel adsorber 30 is composed of a plurality of carbon dioxide adsorption box blocks 22, and the carbon dioxide adsorption box blocks 22 is filled with carbon dioxide adsorption materials, and the carbon dioxide adsorption box blocks 22 facilitate the replacement of carbon dioxide adsorption materials.

[0049] When the carbon dioxide adsorption system 2 performs carbon dioxide adsorption and purification, the waste gas to be treated is blown into the carbon dioxide adsorption system 2 from a gas inlet A through a windmill 5, and first flows through the humidity conditioner 10. The humidifier 10 is a combination of a shell-and-tube heat exchanger and a steam humidifier, which has the functions of temperature adjustment and humidif...

Embodiment 3

[0051] A carbon dioxide adsorption system 3 according to the third specific embodiment of the present invention is as follows: Figure 4 As shown, the system includes: a humidity conditioner 10 and a honeycomb rotary adsorber 40; wherein the honeycomb rotary adsorber 40 is composed of a plurality of modified multi-channel honeycomb carbon dioxide adsorption substrates. to make.

[0052] When the carbon dioxide adsorption system 3 performs carbon dioxide adsorption and purification, the waste gas to be treated is blown into the carbon dioxide adsorption system 3 from a gas inlet A through a windmill 5, and first flows through the humidity conditioner 10. The humidifier 10 is a water washing tower with functions of evaporative humidification and cooling to adjust the humidity of the waste gas to be treated, and then the humidified waste gas to be treated enters the honeycomb rotary adsorber 40, and the to-be-treated waste gas The carbon dioxide in the treated waste gas is adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap