Method for preparing ditrimethylolpropane tetraacrylate

A technology of bis-trimethylolpropane tetraacrylate and bis-trimethylolpropane is applied in the field of synthesis and preparation of chemical products, and can solve the problems of material polymerization, low product yield, inability to meet the needs of high-quality products, and the like, Achieve the effect of improving product yield, high product purity, and solving product color depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

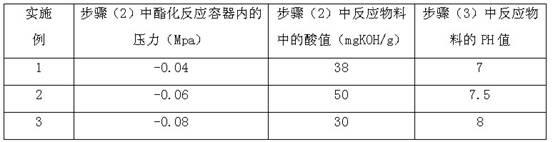

Examples

Embodiment Construction

[0012] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and the details are as follows:

[0013] A preparation method of ditrimethylolpropane tetraacrylate, comprising the following steps:

[0014] (1) The same as the existing atmospheric pressure esterification method, put the main materials ditrimethylolpropane and acrylic acid into the esterification reaction container, and use 50-50% of the total mass percentage of ditrimethylolpropane and acrylic acid Add 90% toluene, add p-toluenesulfonic acid according to 1.2-4.2% of the total mass percentage of ditrimethylolpropane and acrylic acid, add phenothiene according to 0.3-0.5% of the total mass percentage of ditrimethylolpropane and acrylic acid Oxyzine was stirred for 2 to 9 hours to carry out an esterification reaction to obtain a reaction material;

[0015] (2) Turn on the vacuum pump on the esterification reaction vessel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com