Water-based paint dispersing technology

A water-based paint and dispersion technology, applied in the direction of pigment slurry, etc., can solve the problems of difficulty in grinding fineness of 15μm, difficulty in cleaning and color changing, low production efficiency, etc., to achieve high product quality, high quality, and reduce the use of additives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

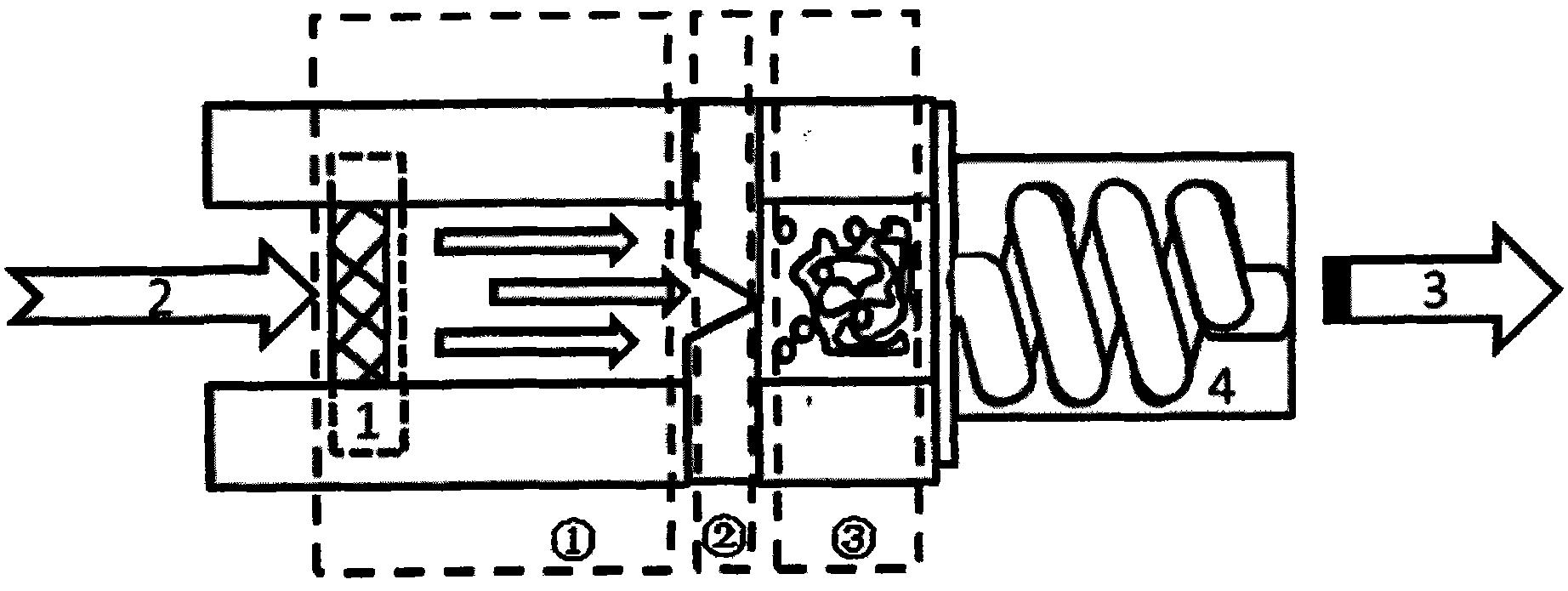

[0059] A kind of white water-based paint color paste, after preliminary pre-dispersion (as shown in 2), enters such as figure 1 The water-based paint is shown in the dispersion process flow channel. After passing through the filter screen of the first flow channel (as shown in ①) (as shown in 1), it reaches the Figure 4 In the inlet end (as shown in 9) of the second flow channel (as shown in ②) of the garden platform type shown, the white water-based paint color paste passes through the second flow channel in a very short time under the pressure of the 250bar pressure pump. Connect the outlet end (as shown in 8) of the third runner (as shown in ③) to extrude, under the action of great shearing force, the particles (as shown in I) of white water-based paint color paste agglomeration are formed Such as Figure 7 The turbulence or vortex shown break away from the gravitational effect between each other to achieve the dispersion effect (as shown in II), and enter the serpentine...

Embodiment 2

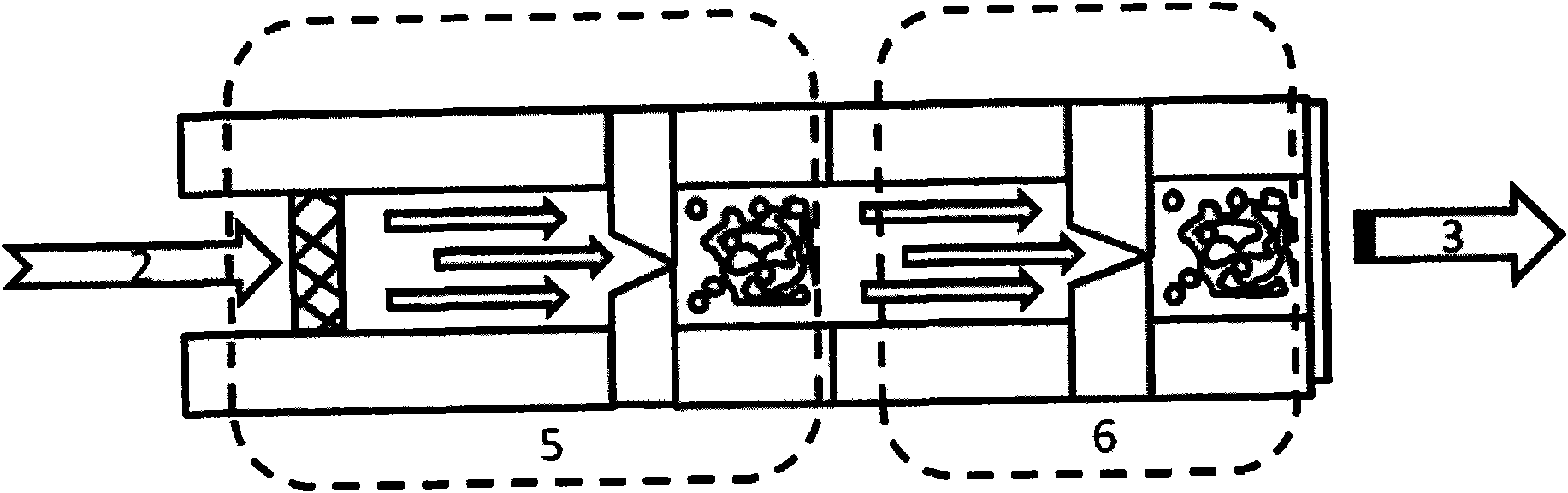

[0061] An orange water-based paint color paste, after preliminary pre-dispersion, enters such as figure 2 As shown, there are two process units (as shown in 5 and 6) in the water-based paint dispersion process flow channel. After filtering through the filter screen (as shown in 1) of the first process unit (as shown in 5), it reaches the inlet end of the second flow channel of the first process unit's conical shape. Under the action of pressure, after a very short time, it is extruded from the outlet end of the second flow channel of the first process unit connected to the third flow channel. Or get rid of the gravitational effect between each other in the eddy current to reach a certain degree of dispersion, and then enter the next process unit (single process unit process such as Figure 5 Shown); enter into the serpentine flow channel that connects the 3rd flow channel of the second process unit after being further dispersed through the next process unit (as shown in 6) t...

Embodiment 3

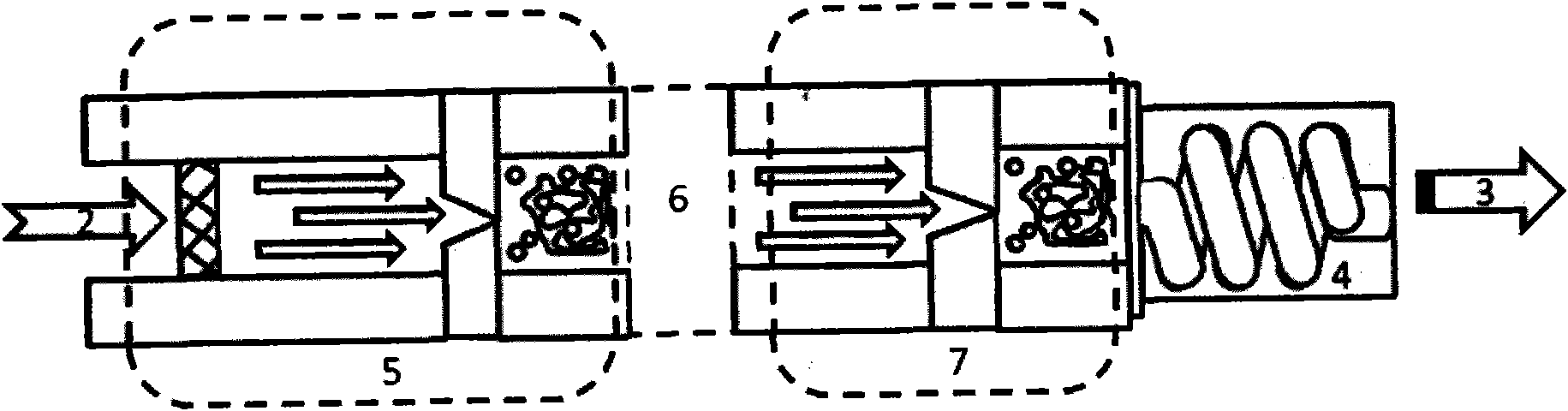

[0063] A phthalo-green water-based paint color paste, after pre-dispersion, enters such as image 3 As shown, there are 5 process units (shown as 5, 6, and 7) in the water-based paint dispersion process flow channel. After being filtered by the filter screen of the first channel of the first process unit, it reaches the second channel of the conical shape of the first process unit, such as Figure 6 In each of the sub-channels shown, the phthalo-green water-based paint color paste is extruded from the outlet ports of the multiple sub-channels connecting the second channel to the third channel after a very short period of time under the pressure of the 700bar pressure pump. Under the action of great shearing force, the agglomerated particles of phthalo-golden slurry break away from the gravitational force between each other in turbulence or vortex, enter the next process unit, and continue to disperse; after 5 process unit cycle operations Finally, the third flow channel that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com