Temperature self-compensation FBG (Fiber Bragg Grating) refractive index sensor based on conical corrosion

A refractive index sensor and refractive index technology, which are applied in the measurement of phase influence characteristics, cladding fibers, optical waveguides and light guides, etc., can solve problems such as cross-sensitivity, achieve compact structure, reduce sensor cost, and facilitate transmission of multi-point distribution in space. The effect of sensory measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

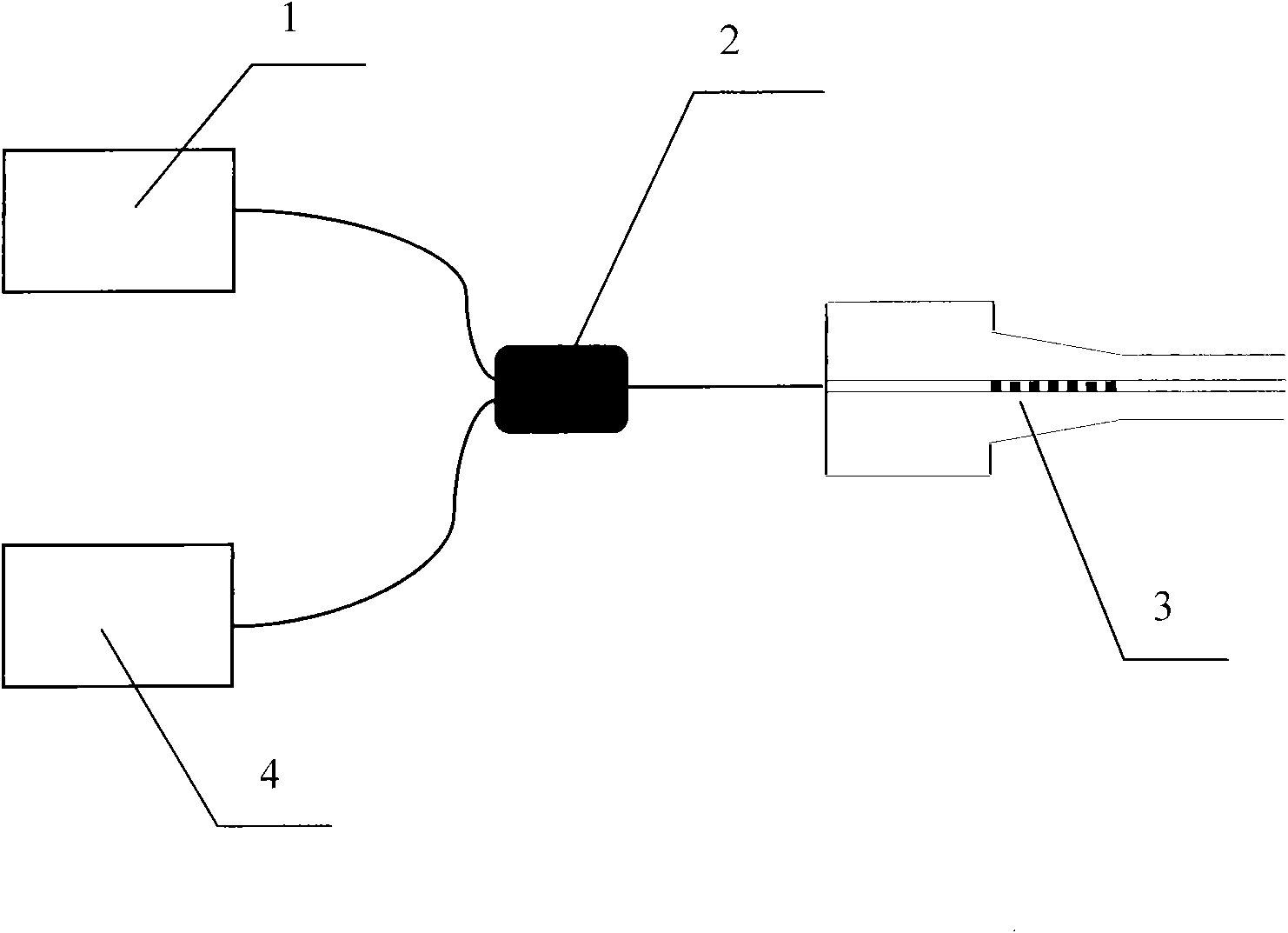

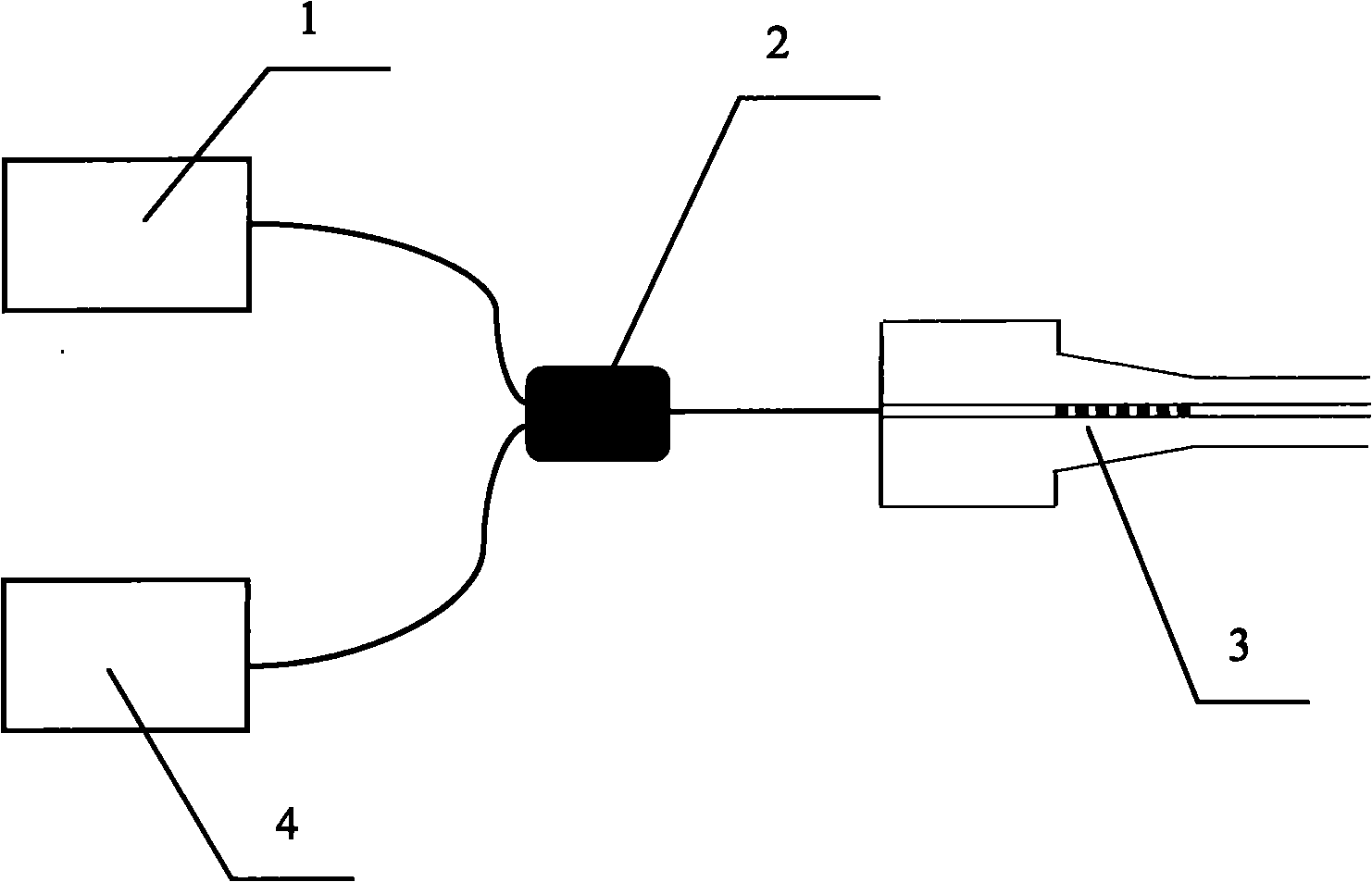

[0013] Such as figure 1 As shown, the temperature self-compensating FBG refractive index sensor based on tapered erosion includes a broadband light source 1, a 3dB coupler 2, a tapered etched fiber Bragg grating 3, and a spectrometer 4. One end of the broadband light source 1 is optically connected to the first port of the 3dB coupler 2, the second port of the 3dB coupler 2 is optically connected to one end of the tapered-corroded fiber Bragg grating 3, and the third port of the 3dB coupler 2 is connected to the Spectrometer 4 optical connections.

[0014] The working mode of this embodiment is: the light emitted by the broadband light source enters the tapered corroded fiber Bragg grating through the 3dB coupler, and the reflected light from the tapered corroded fiber Bragg grating is transmitted into the spectrometer through the 3dB coupler. Since the cladding of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

| Minimum diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com