Hyperelastic hose cryoprobe

A cryoprobe and superelastic technology, applied in the field of medical devices, can solve problems such as bending of easily broken endoscopes, and achieve the effects of being difficult to break, extending the treatment range, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

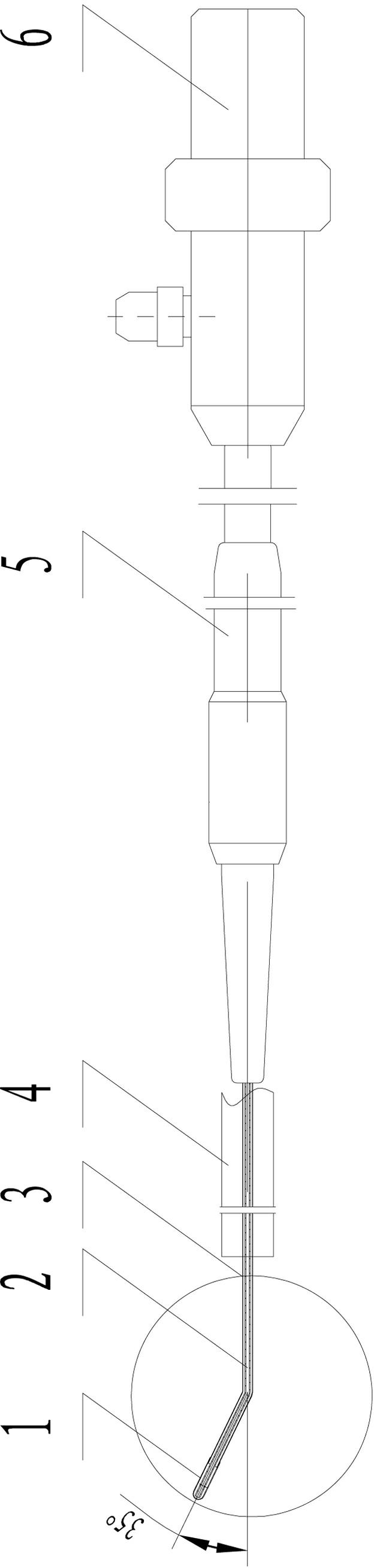

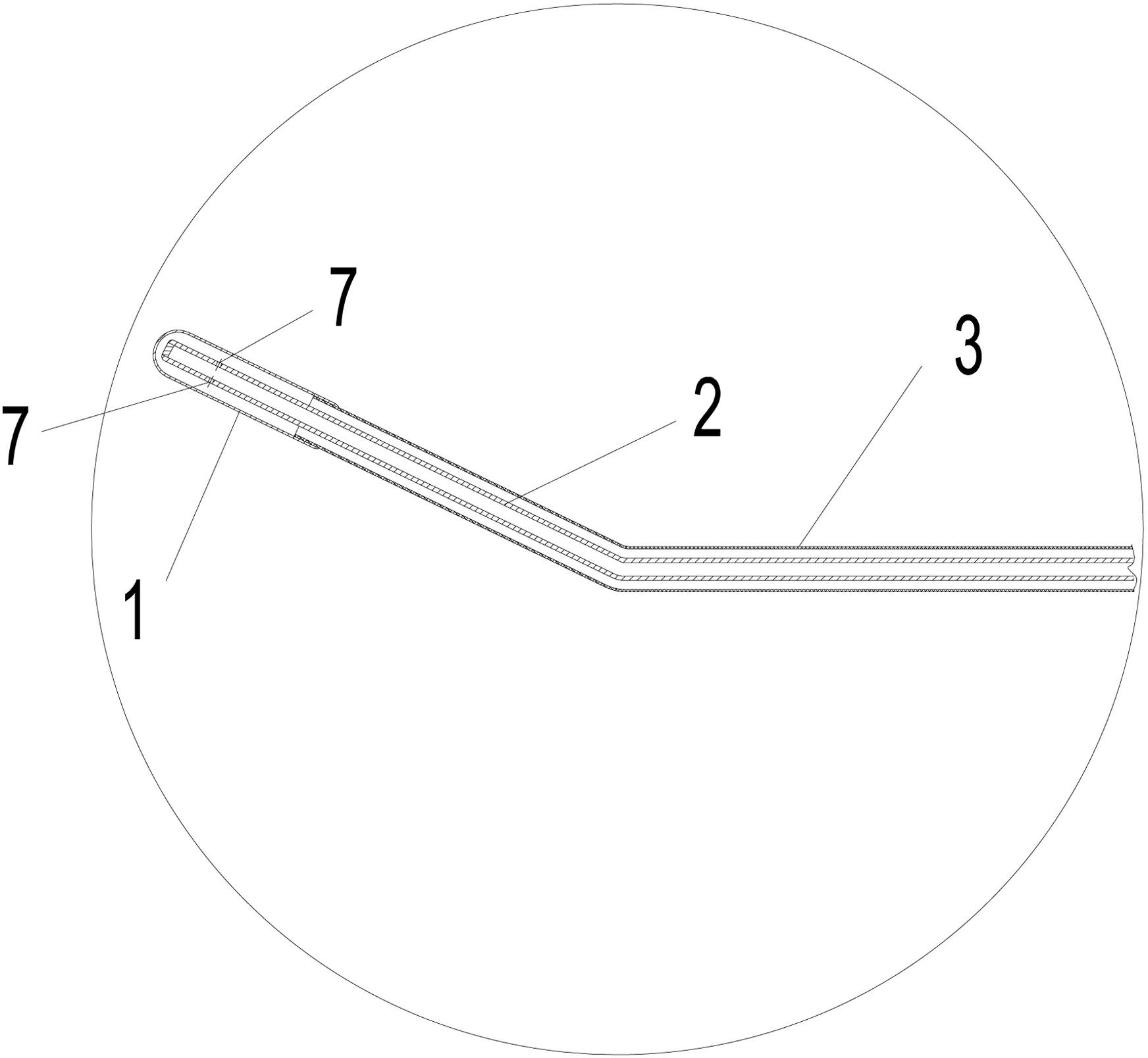

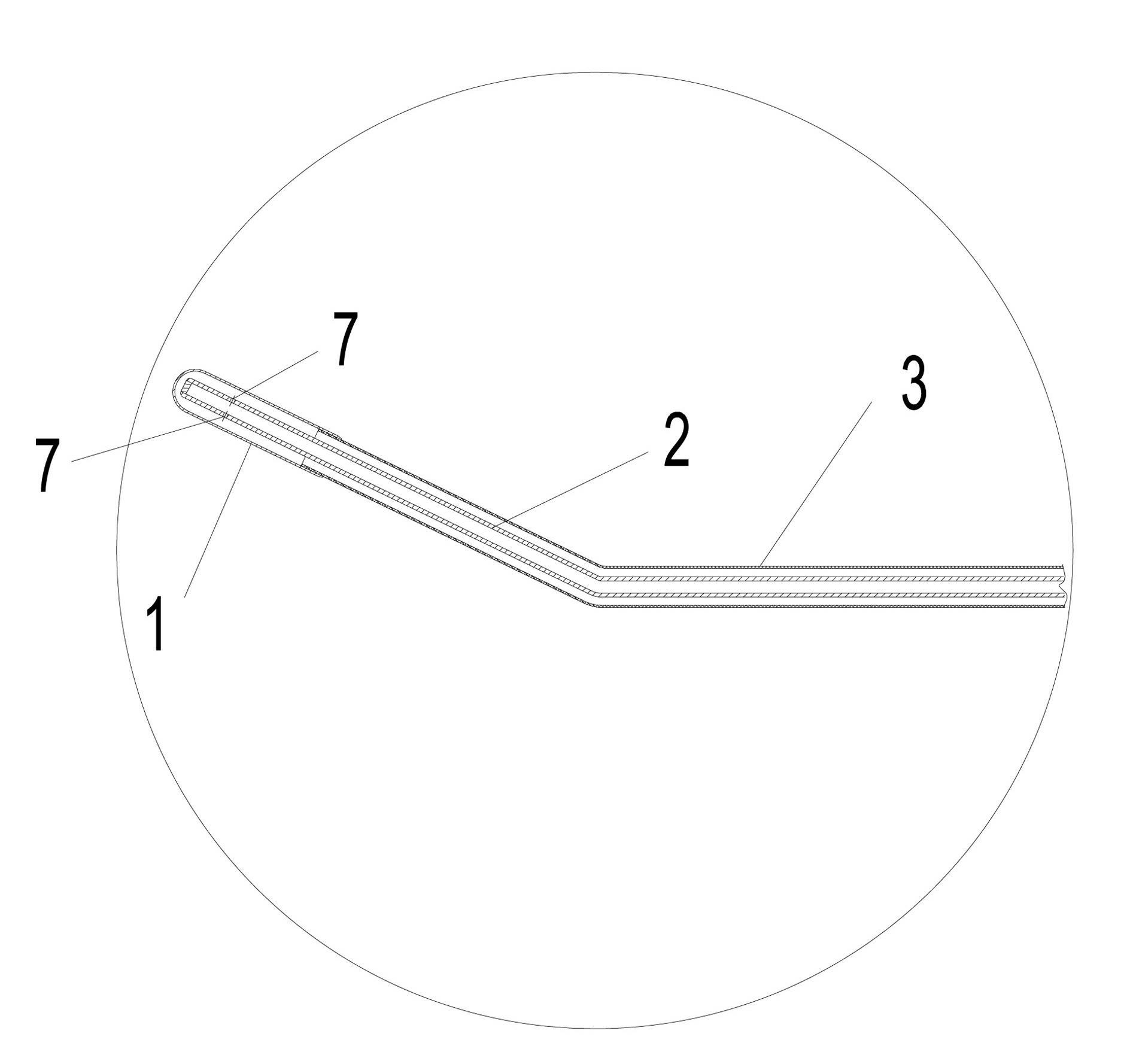

[0014] see figure 1 , figure 2 Shown: a kind of superelastic hose cryoprobe, it comprises probe handle 5,. Probe connecting seat 6, is connected with superelastic air inlet pipe 2 at the front end of probe handle 5, in the superelastic air inlet pipe 2 A hose probe outer tube 3 is sheathed on the outside, and a cold head 1 is connected to the front end of the hose probe outer tube 3. The front end of the superelastic air inlet pipe 2 is arranged in the cold head 1. The superelastic air inlet pipe 2 The front end rear portion of the superelastic air intake pipe 2 is curved, and the front end of the superelastic air intake pipe 2 is closed, and a throttle hole 7 is arranged on the side wall of the front end rear portion of the super elastic air intake pipe 2 .

[0015] The superelastic intake pipe 2 is made of memory nickel-titanium alloy material.

[0016] The said orifice 7 is a radial hole, and there are two oppositely arranged.

[0017] The front and rear of the superela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com