Joint magnetic flotation sorting method for complex magnetic pyrite copper-containing pyrite ore

A technology for pyrrhotite and iron ore, which is applied in the beneficiation field of copper pyrrhotite ore, can solve the problems of difficult activation, loss of pyrite ore, waste of resources, etc., and achieve reduction of lime consumption, efficient collection, and reduction of interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

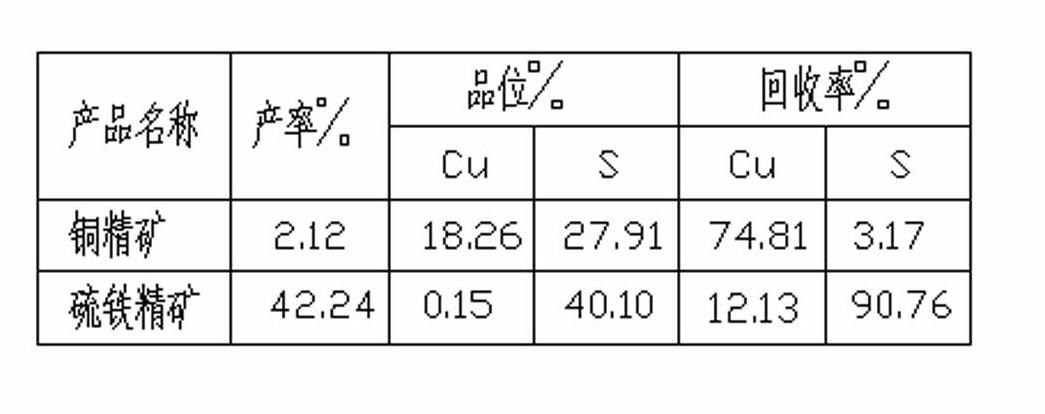

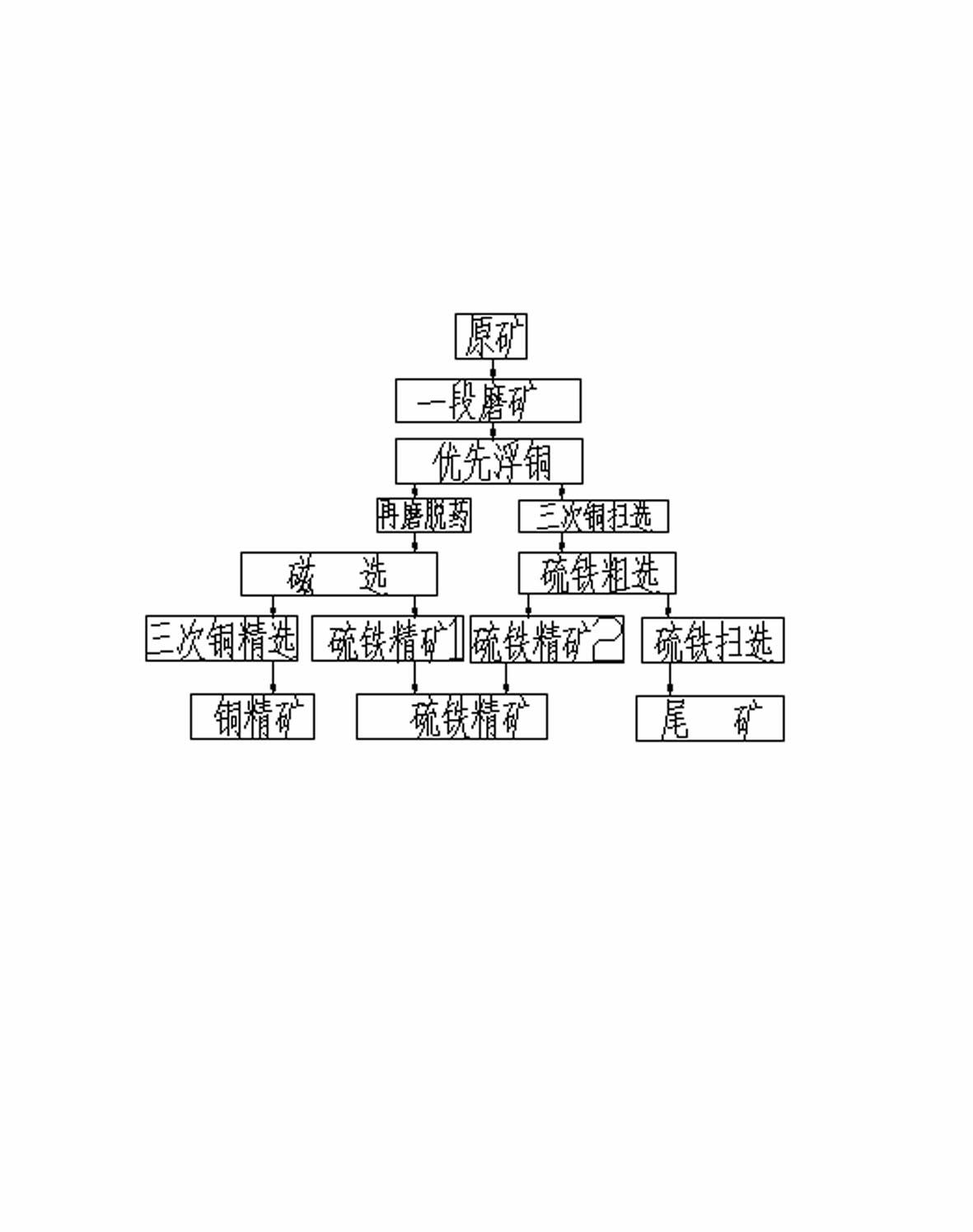

[0035] Example 1: Copper pyrite ore raw ore contains 0.52% copper and 18.66% sulfur. First add lime to the ball mill and grind the raw ore to -0.074mm, accounting for 80%; add inhibitor DB-5 and stir for 3 minutes according to the drug system in Table 3, add DY copper sulfide ore collector and stir for 2 minutes to carry out preferential floating copper (pH =8-9); floating copper tailings were added with collector DY for copper scavenging three times; priority floating copper concentrate was added to activated carbon for regrinding and drug removal, and copper coarse concentrate was reground to -0.074mm, accounting for about 90%; Under the magnetic field strength of 0.45 T, the reground copper concentrate was subjected to magnetic separation to remove part of the pyrrhotite, and pyrrhotite concentrate 1 was obtained; the magnetic separation tailings were added with inhibitor DB-4 and stirred for 5 minutes, DB-5 and ZnSO 4 Stir for 3 minutes, and collector DY for 2 minutes for ...

example 2

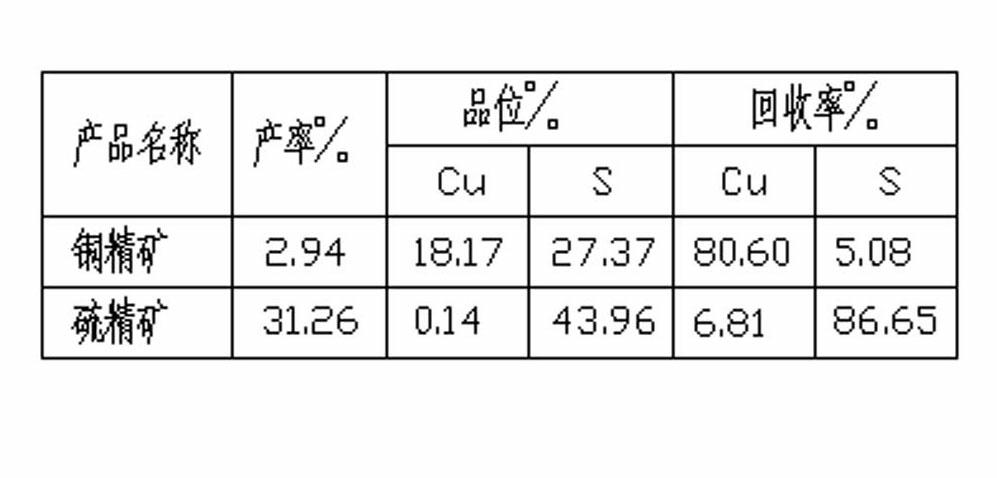

[0036] Example 2: The raw ore of copper pyrite containing 0.66% copper and 15.86% sulfur was tested by applying the above process under the same steps and chemical system conditions. First, lime was added to the ball mill to grind the raw ore to -0.074mm 80%; press Figure 4 Add inhibitor DB-5 and stir for 3 minutes, add DY copper sulfide collector and stir for 2 minutes to carry out preferential floating copper (pH=8-9); add collector DY to floating copper tailings to carry out three copper Sweeping; the priority is to add activated carbon to the floating copper concentrate for regrinding to remove the drug, and the copper coarse concentrate is reground to -0.074mm, accounting for about 90%; under the magnetic field strength of 0.45 T, the reground copper concentrate is removed by magnetic separation pyrrhotite, and get pyrite concentrate 1; add inhibitor DB-4 to magnetic separation tailings and stir for 5 minutes, DB-5 and ZnSO 4 Stir for 3 minutes, and collector DY for 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com