Image centralizing location method for automatic tube plate welding

A technology of automatic welding and positioning method, which is applied in the field of image centering and positioning, can solve problems such as no technical means, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Embodiment: An image centering and positioning method for automatic welding of tube sheets

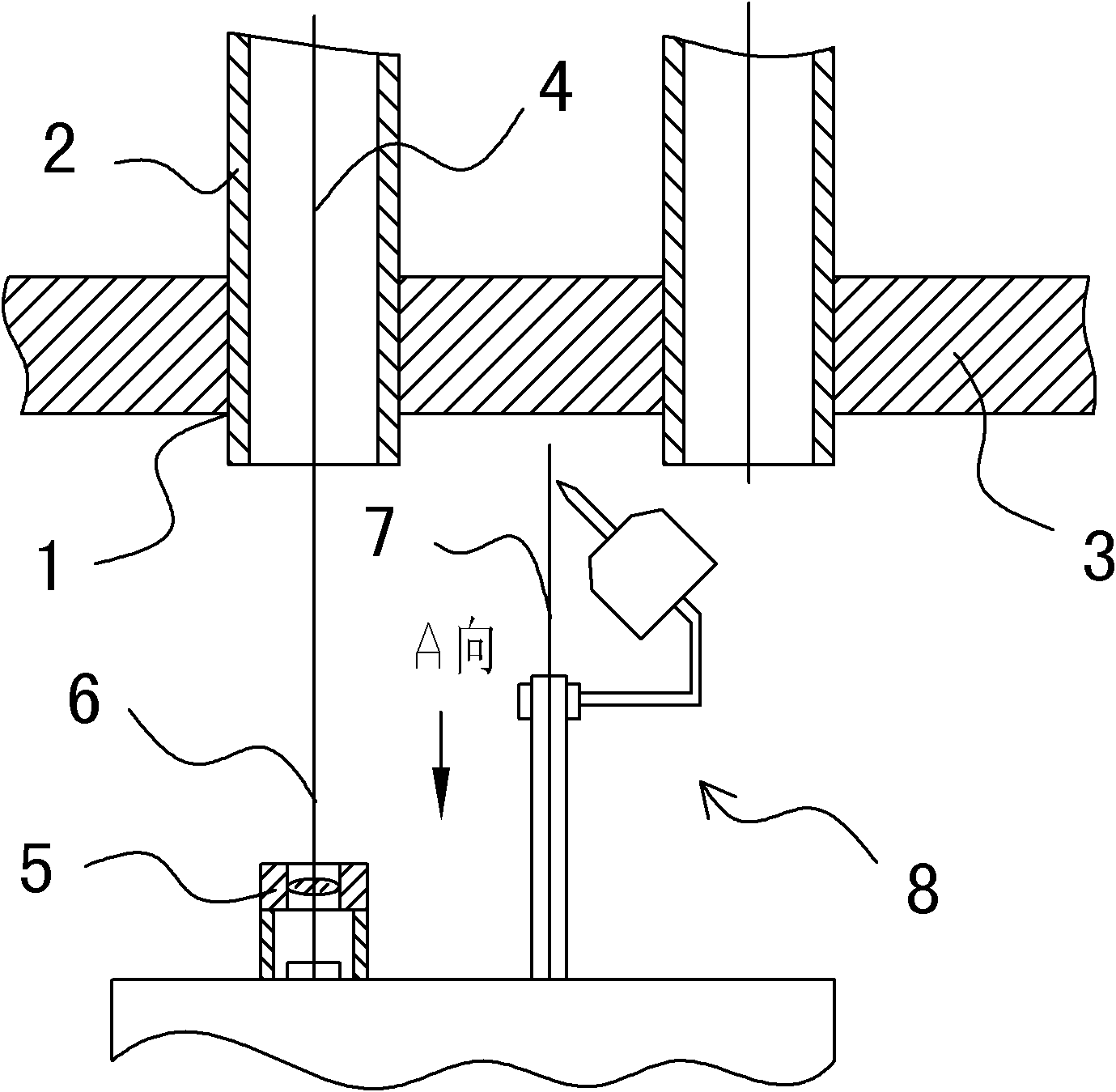

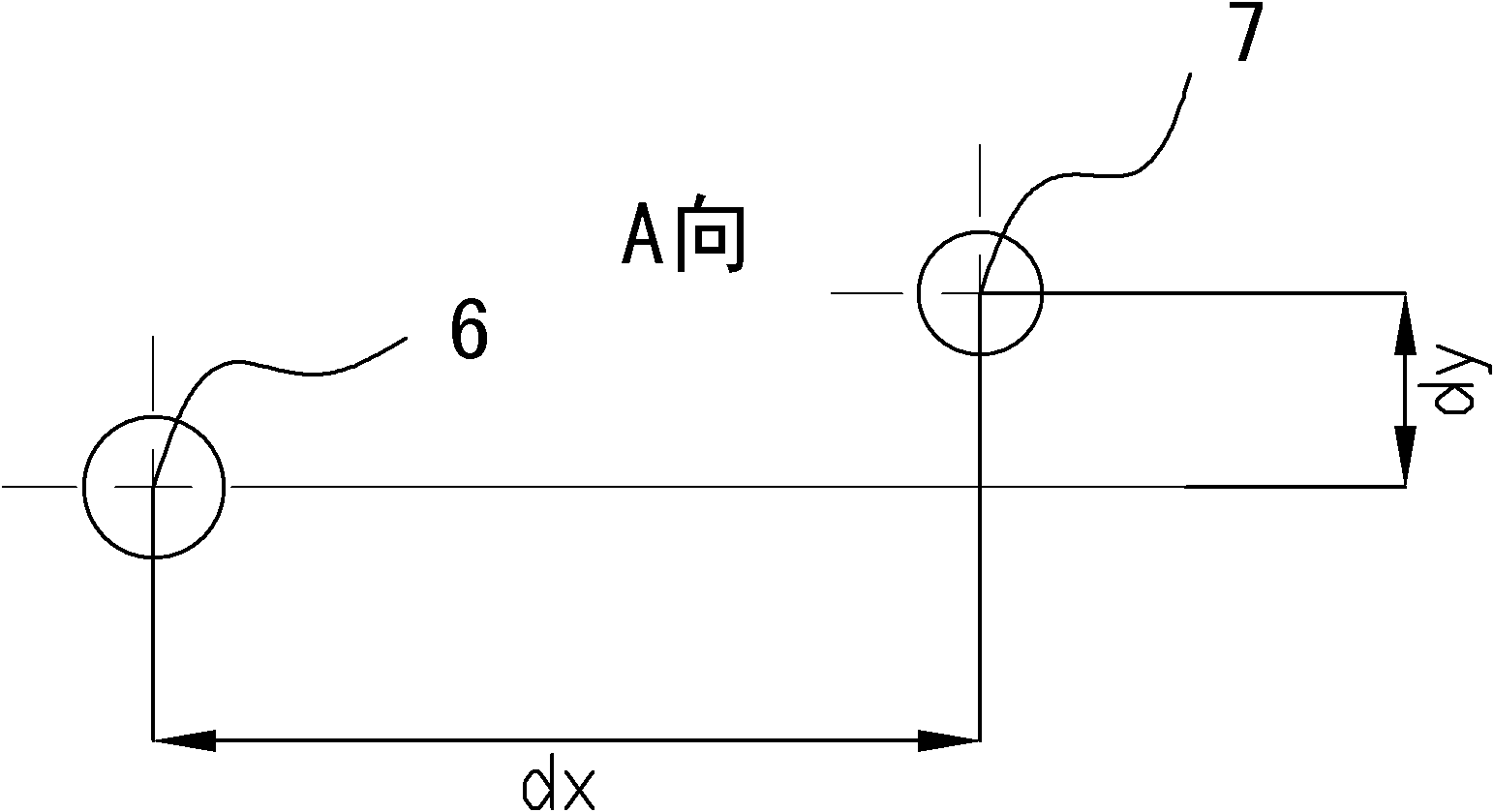

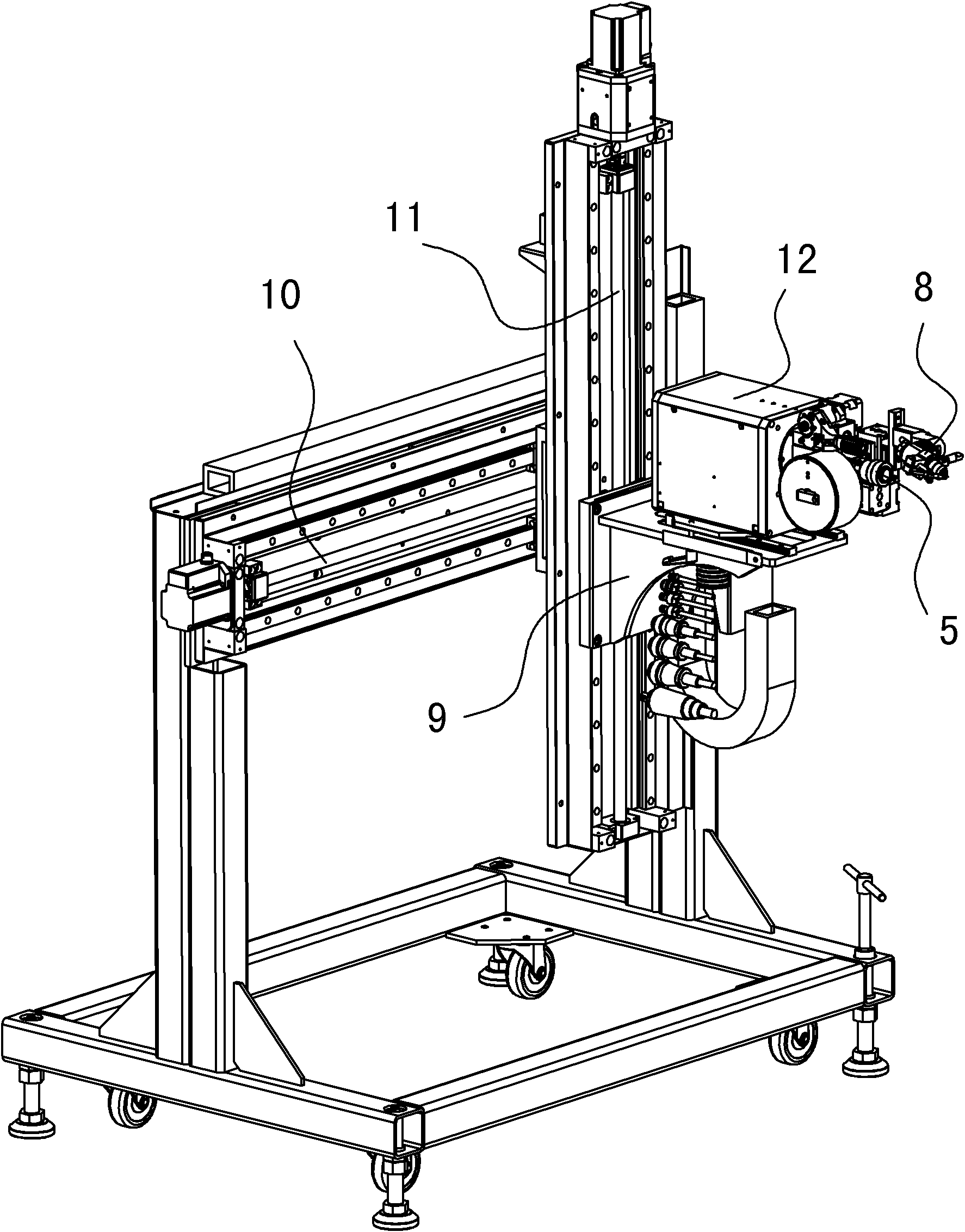

[0056] See attached Figure 1~Figure 8 As shown, the present invention is aimed at the image centering and positioning method adopted for the automatic welding of pipe 2 and plate 3. The first task is to use image processing technology to find the position of the center of circle 15 of the welded pipe mouth; the second is to use the X-axis moving mechanism 10 and The Y-axis moving mechanism 11 translates the rotation central axis 7 of the welding torch to the center 15 of the welded pipe mouth 1 for positioning. To put it simply, it is to take an image 13 of the nozzle to be welded, find the center 15 of the nozzle on the image, and drive the X-axis moving mechanism 10 and the Y-axis moving mechanism 10 so that the rotation axis 7 of the welding torch is aligned with the center of the nozzle 1 of the welded pipe. 15 overlap, you can start welding work. The content of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com