Three-mode power transmission device for hybrid vehicle

A technology for a power transmission device and a hybrid vehicle, which is applied to the transmission device field of a vehicle, can solve problems such as complex structure, and achieve the effects of compact mechanical structure, stable engagement and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

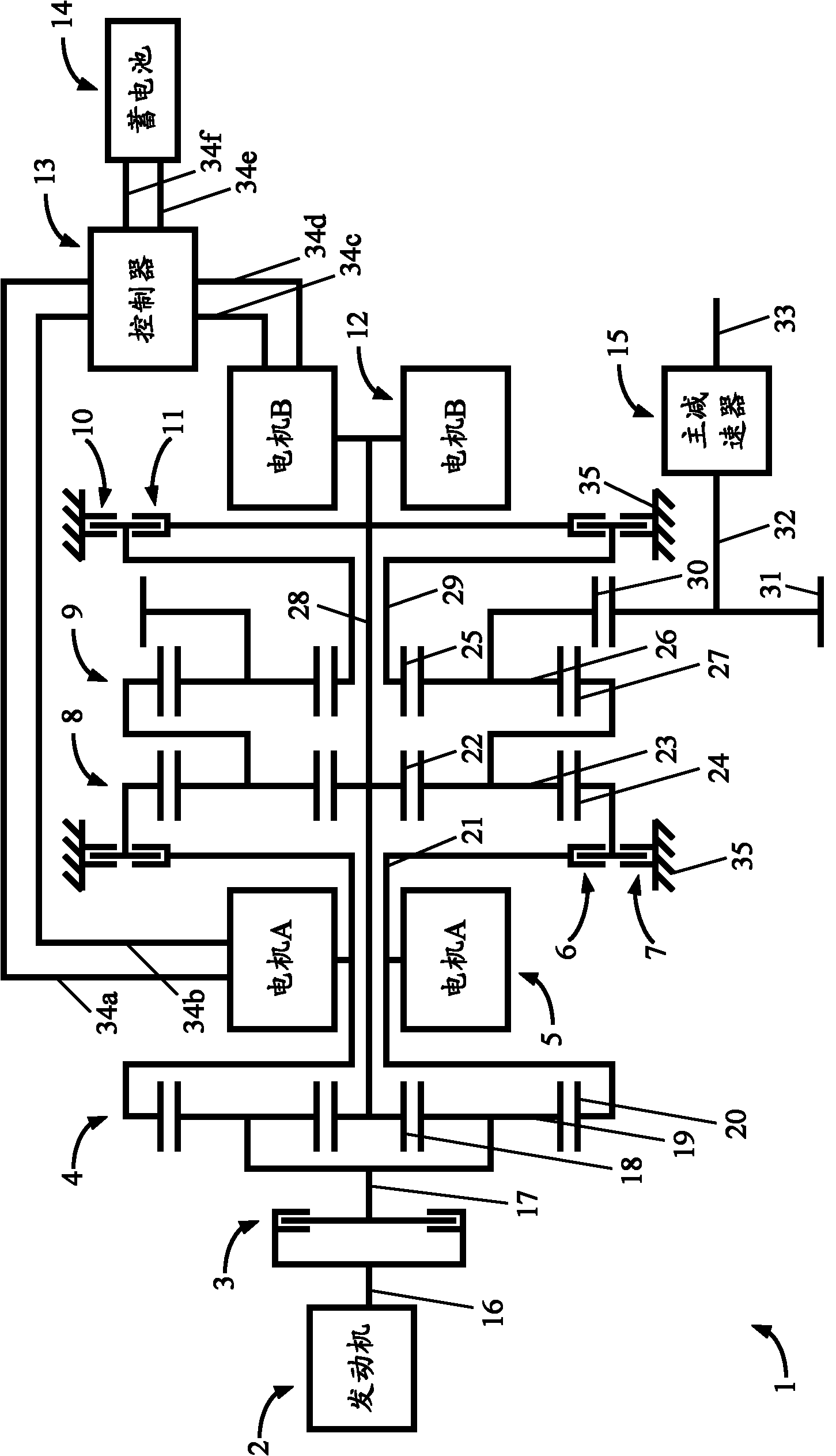

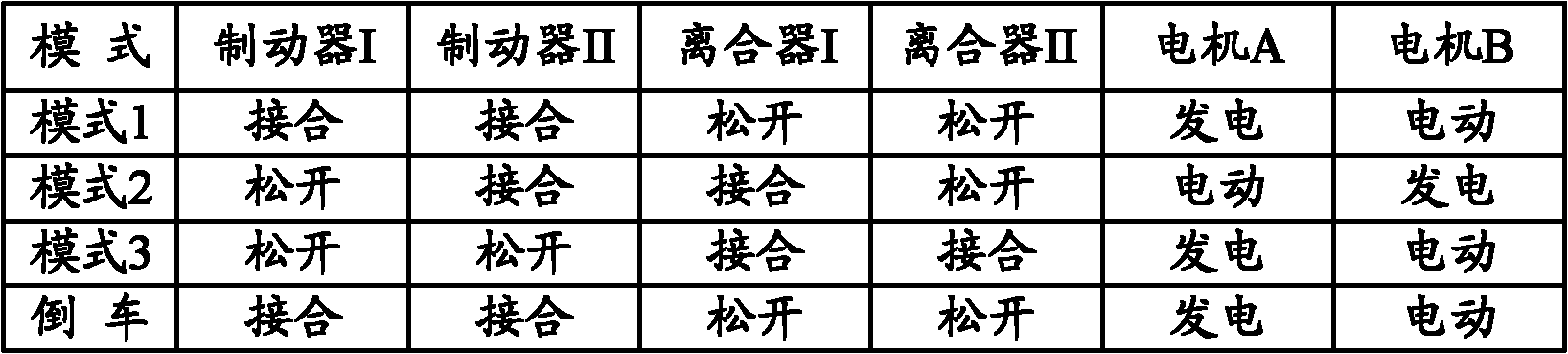

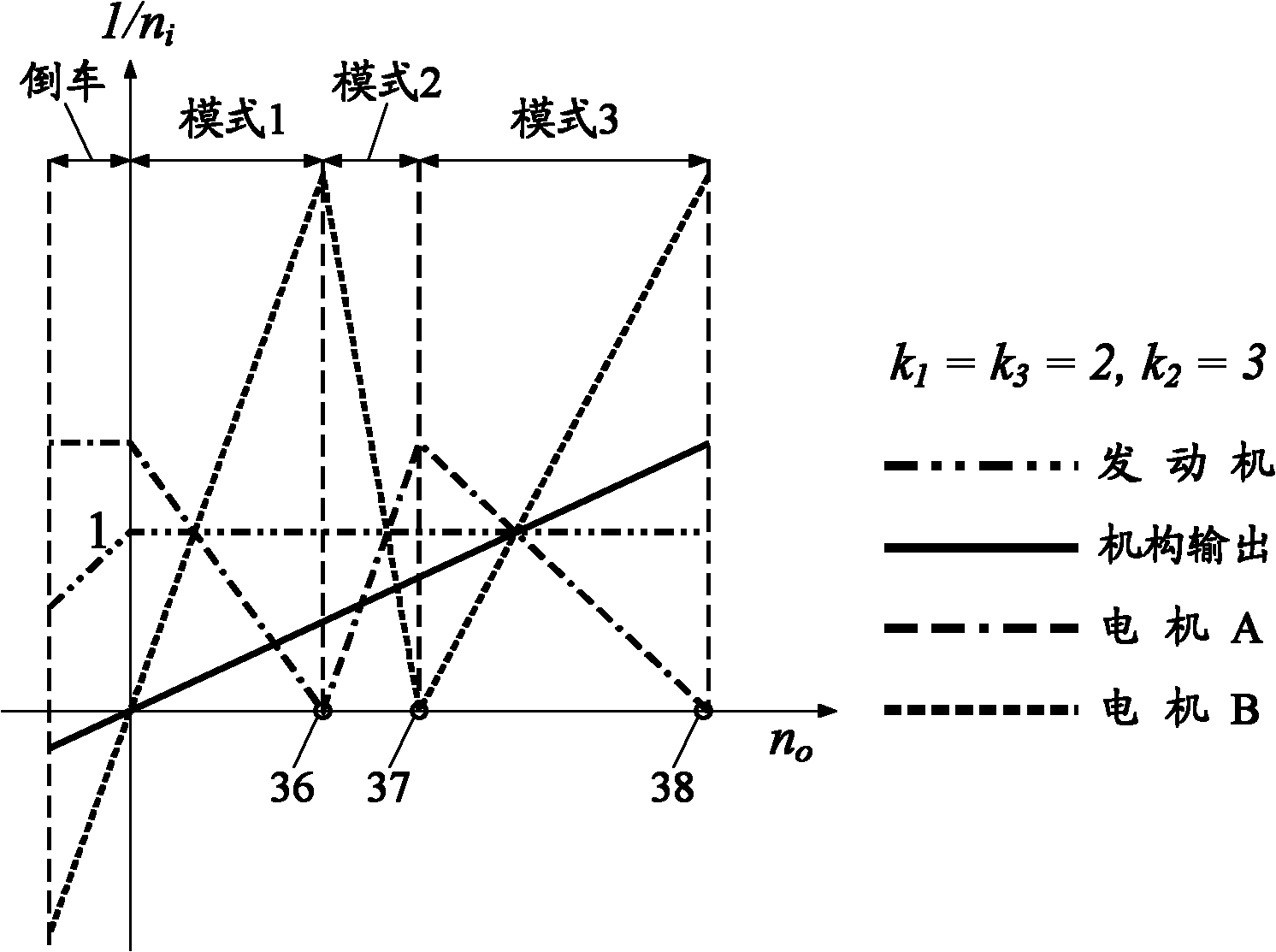

[0031] figure 1 Shown is the electromechanical compound three-mode power transmission device of the present invention, which is marked with reference number 1 . In the illustrated embodiment, the engine 2 is a diesel engine, which outputs power to the system at a constant speed. The electromechanical composite power transmission device has two driving states of the vehicle forward and reverse, wherein the forward state is subdivided into three working modes.

[0032] figure 1 Shown is a simplified structural diagram of the three-mode power transmission device, and the details are as follows:

[0033] The three-mode power transmission of the hybrid vehicle, including:

[0034] The main clutch 3 for receiving power from the engine, which is installed between the engine and the electromechanical compound transmission, and is used to connect / cut off the connection between the engine and the transmission;

[0035] The main reducer transmits the power output by the third planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com