High efficient multifunctional wastewater treatment system

A wastewater treatment system and multi-functional technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem that the effect of phosphorus removal is not very ideal and cannot be continuous Stable operation, failure to achieve the desired effect and other problems, to achieve the effect of increased aeration volume utilization, low sludge index SVI value, and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

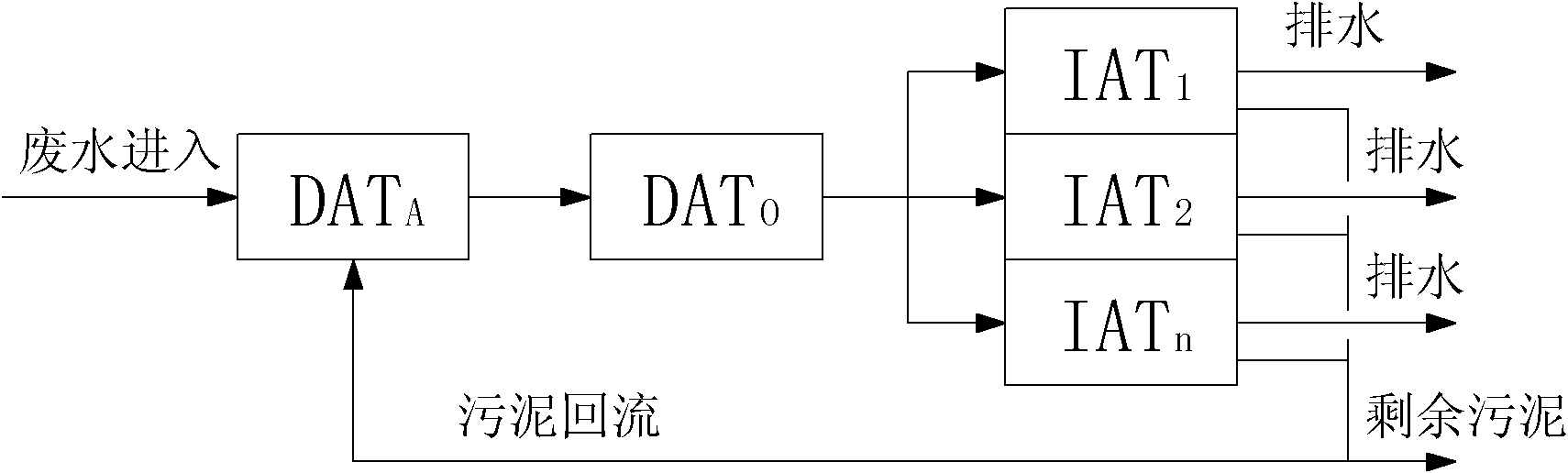

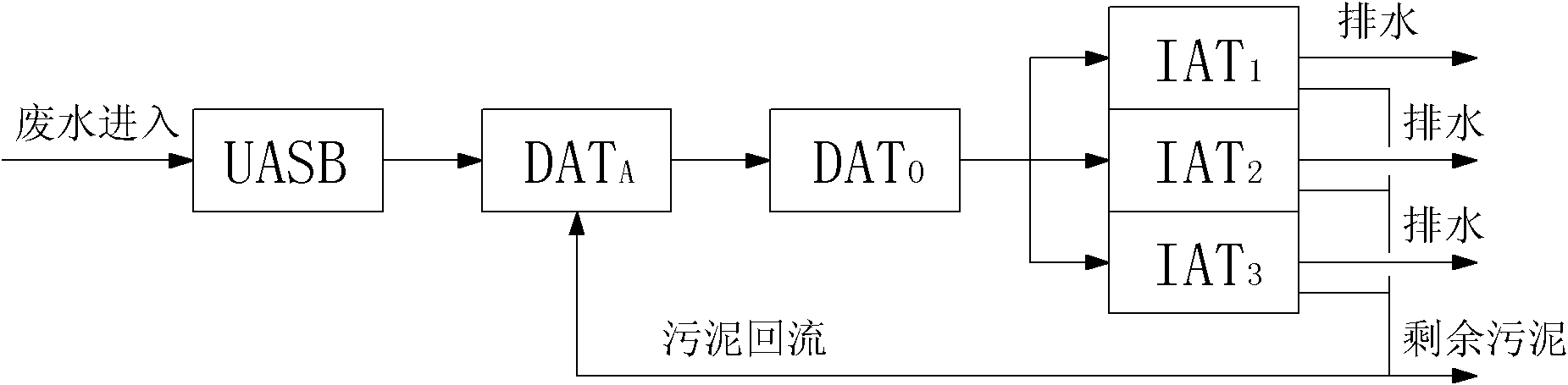

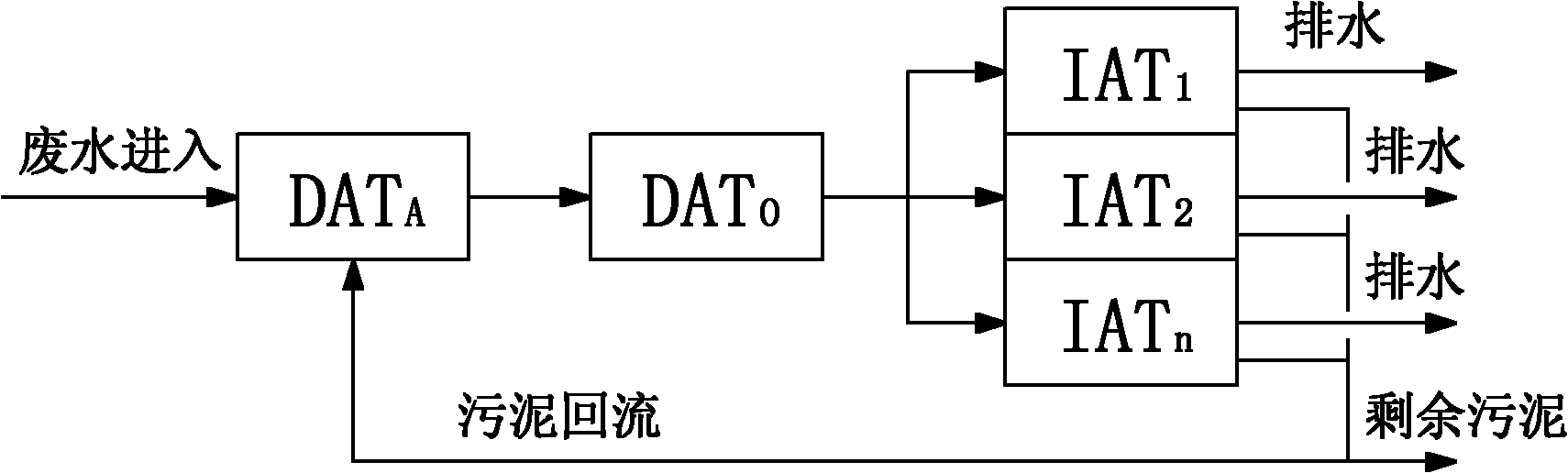

[0037] Such as figure 1 As shown, the high-efficiency multifunctional wastewater treatment system includes DATs connected in series A Pool, DAT O The pool and the IAT pool constitute the DAT A-DAT O -IATn process, where DAT A The tank is a pre-aeration section, which has the functions of pre-aeration, hydrolysis acidification, biological selection, etc.; DAT O The pool is an aerobic aeration section, where the wastewater is continuously aerated, and the pollutants are continuously degraded and transformed under the action of aerobic oxygen. The IATn pool treatment section is a group of reaction pools connected in parallel with the same function. Wastewater enters each pool alternately according to a certain time sequence, and completes processes such as aeration, sedimentation, drainage, and idleness respectively to achieve the removal of pollutants.

[0038] The present invention will be further elaborated below in conjunction with specific embodiment:

[0039] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com