Power supply circuit for automobile

A technology of power supply circuit and charging circuit, which is applied in the direction of battery circuit devices, electric vehicles, circuit devices, etc., can solve the problems of ignition circuit inoperability, etc., and achieve the effect of starting the engine easily, increasing stability, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

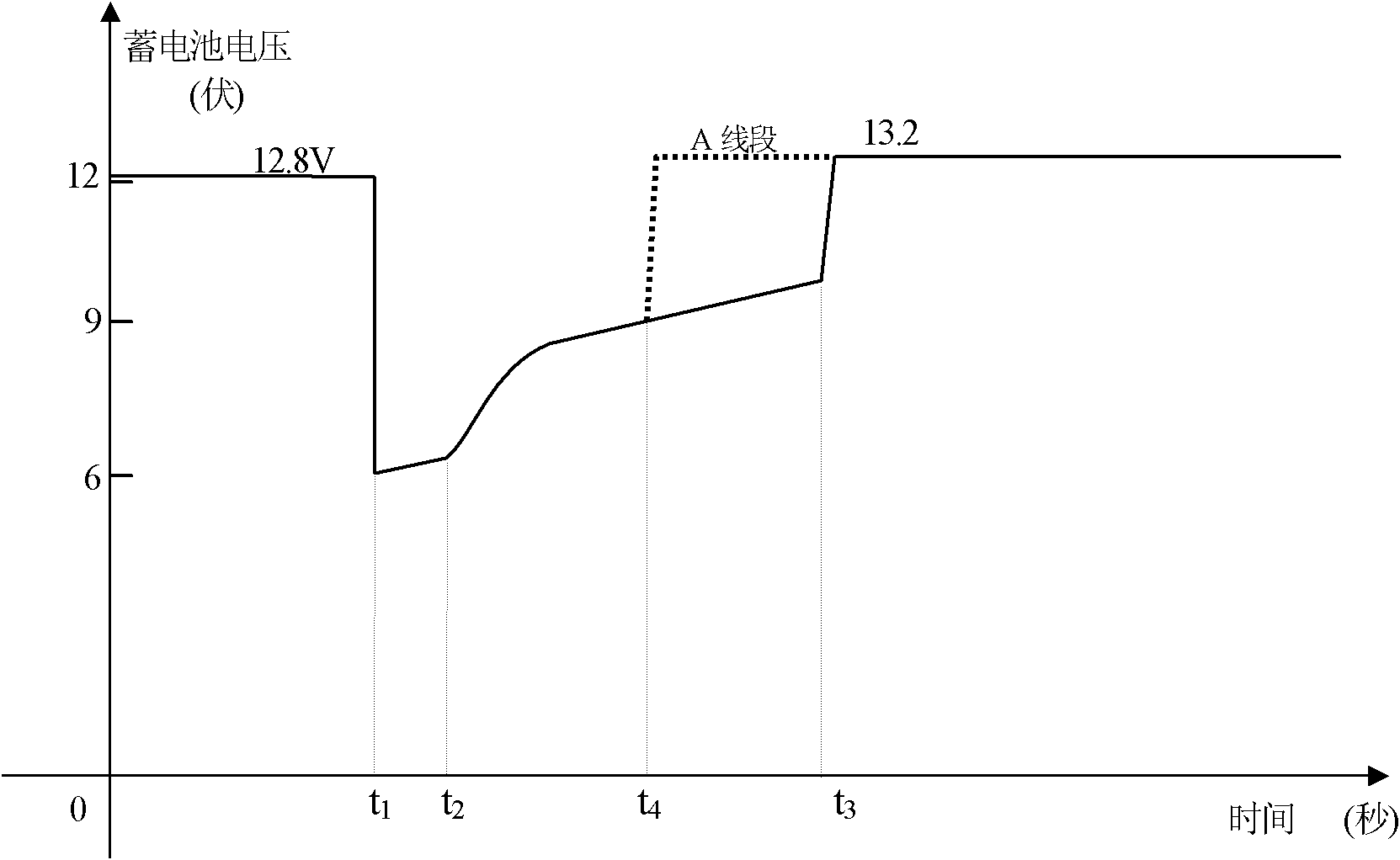

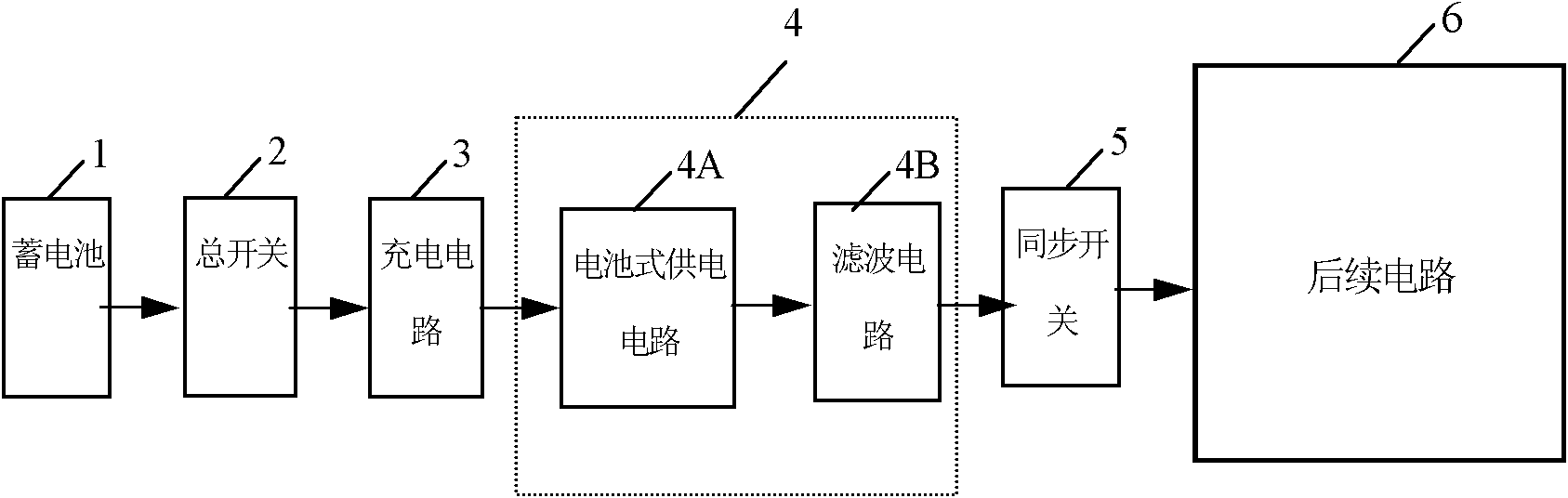

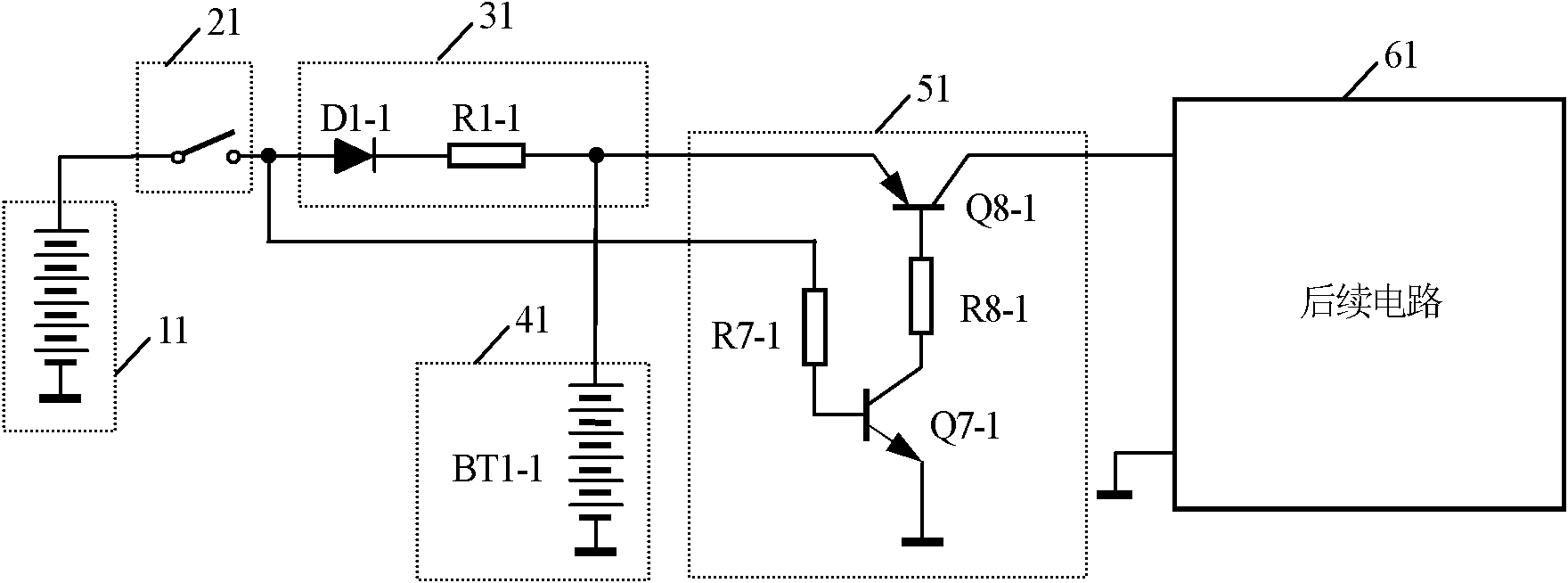

[0058] image 3 The shown embodiment one is a more practical circuit diagram of the present invention, the diode D1-1 and the resistor R1-1 are connected in series to form a charging circuit 31, which is often used in mobile phone chargers; the rechargeable battery BT1-1 forms a battery power supply circuit and The filter circuit 41 is connected to the output end of the charging circuit 31; the resistor R7-1, the NPN transistor Q7-1, the resistor R8-1, and the PNP transistor Q8-1 form a synchronous switch 51, and the emitter of the transistor Q8-1 is connected to the charging circuit 31 The output terminal and the collector are connected to the input terminal of the follow-up circuit 61, the base is connected to the resistor R8-1, the emitter of the triode Q7-1 is grounded, and the collector is connected to the base of the triode Q8-1 through the resistor R8-1. The resistor R7-1 is connected to the input terminal of the charging circuit 31 afterward.

[0059] The working prin...

Embodiment 2

[0068] Figure 4 The second embodiment shown only shows the charging circuit 32, and other functional modules are the same as those of the first embodiment. It is an alternative to the charging circuit in Embodiment 1, such as Figure 4 As shown, the MOS transistor Qt is a P-channel, low-voltage, body-free MOS transistor without a body diode (Body Diode), and its gate is grounded through a resistor Rg, so that its source (S pole) and drain (D pole) are respectively Equivalent replacement for the positive (anode) and negative (cathode) poles of the corresponding diode.

[0069] The working principle of the circuit of this embodiment is: the MOS transistor Qt is a voltage control device, when Figure 4 When connected, the shed of the field effect MOS transistor Qt is grounded through the resistor Rg, and the source voltage is the battery voltage, which is set to 12.8V; at this time, its VGS=-12.8V, which is greater than the turn-on voltage of the MOS transistor, makes the MOS ...

Embodiment 3

[0072] Figure 5 The synchronous switch 53 in the third embodiment shown is a normally open relay RLY, and other functional modules are the same as those in the first embodiment. see Figure 5 After the coil winding of the relay RLY is connected to the original main switch, the other end is grounded; the normally open contact is connected between the rechargeable battery BT1-3 and the follow-up circuit 63 . When the main switch 23 is in the ON state, the relay RLY coil is energized, and the normally open contact becomes closed under the pull-in of the relay, and the voltage of the rechargeable battery BT1-3 is added to the follow-up circuit 63 through the closed contact , the follow-up circuit 63 is energized and works normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com