Blending control method for temperature of reactive kettle

A hybrid control and reactor technology, applied in the field of automation, can solve the problems of low degree of automation, poor control performance, and low precision of control means, and achieve high precision, stability, and simple form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

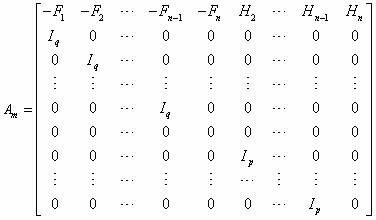

[0058] Take the process control of continuous stirred reactor system as an example:

[0059] Here, the control of the reactor temperature is described as an example. The temperature of the reactor is not only affected by the temperature and flow of the material, but also by the pressure and temperature of the coolant. The adjustment method adopts the coolant flow rate, and the rest of the effects are regarded as uncertain factors.

[0060] (1) Design the proportional integral differential controller for the temperature process of the reactor, and the specific method is the typical response curve method.

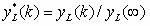

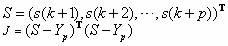

[0061] The first step: Keep the proportional integral differential controller of the reactor temperature in the "manual operation" state, operate the dial of the coolant flow to make the output of the coolant flow controller have a step change, and record the temperature process of the reactor by the recording instrument Output value, the output value of the reactor tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com