Burner arrangement for liquid fuels and method for producing burner arrangement

A burner and fuel technology, which is applied in the direction of gas fuel burners, combustion methods, burners, etc., can solve the problems of unsatisfactory satisfaction of the strength criterion, and can not be realized, so as to reduce the limit heat transfer and reduce the metal The effect of thermal bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

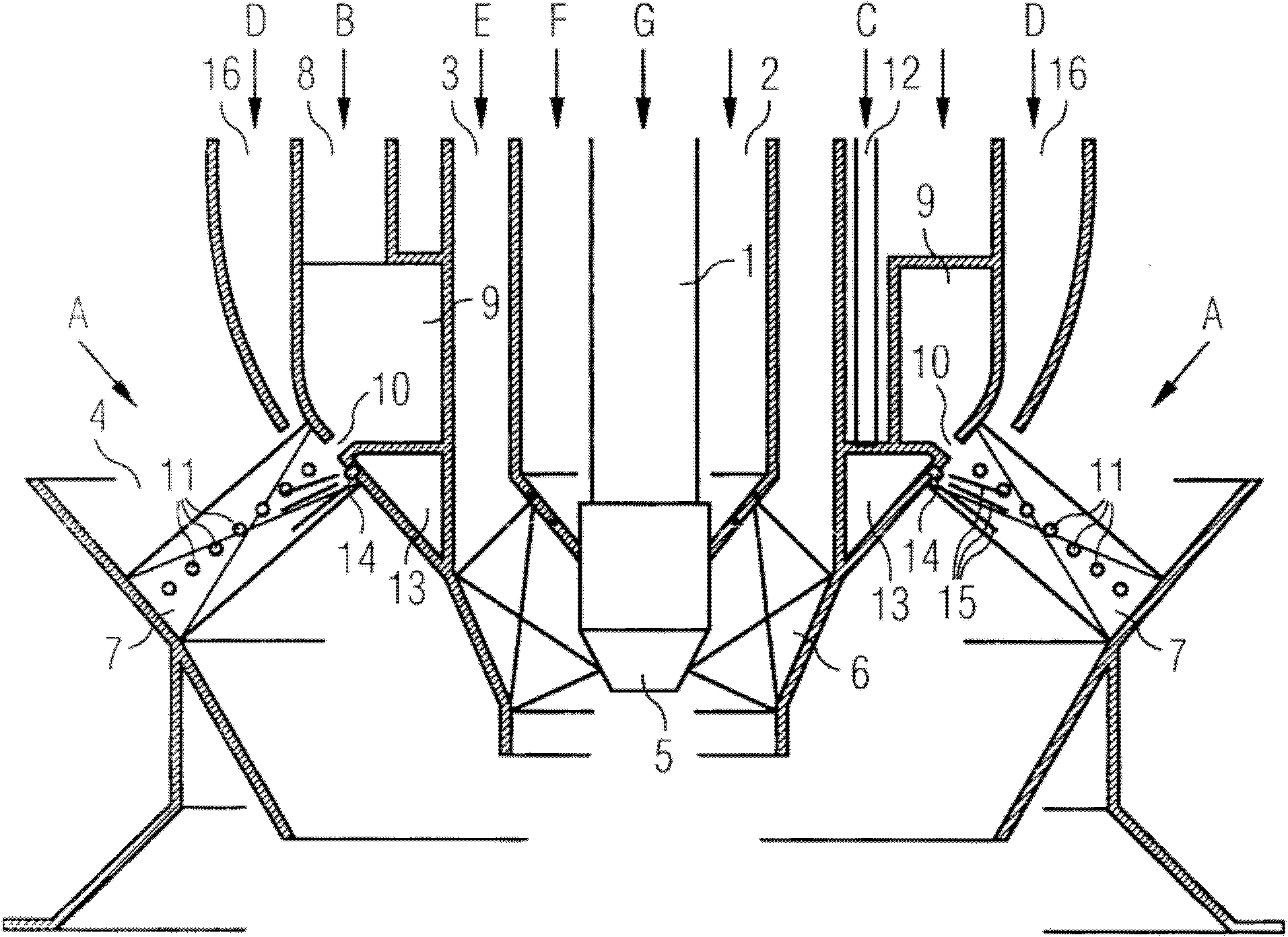

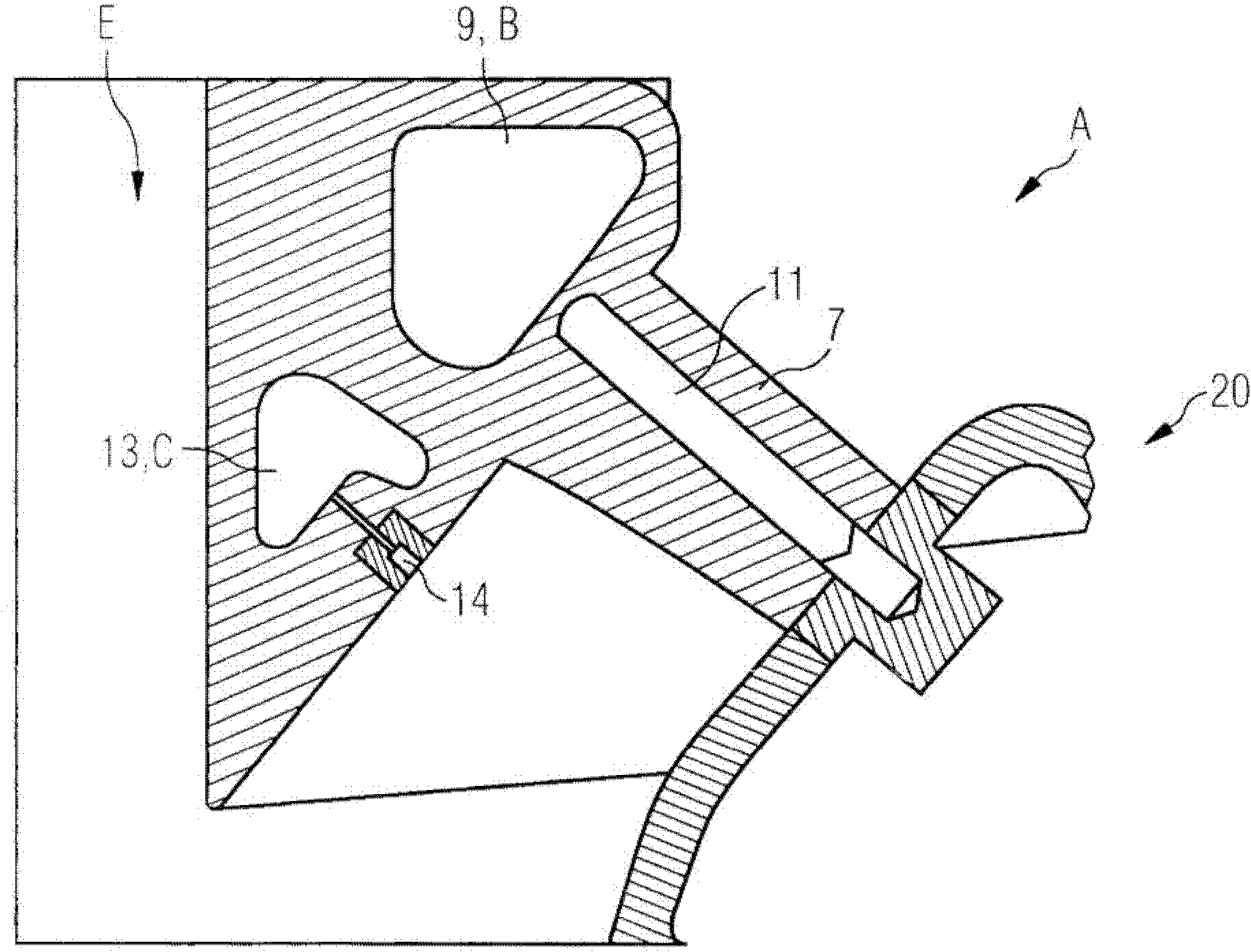

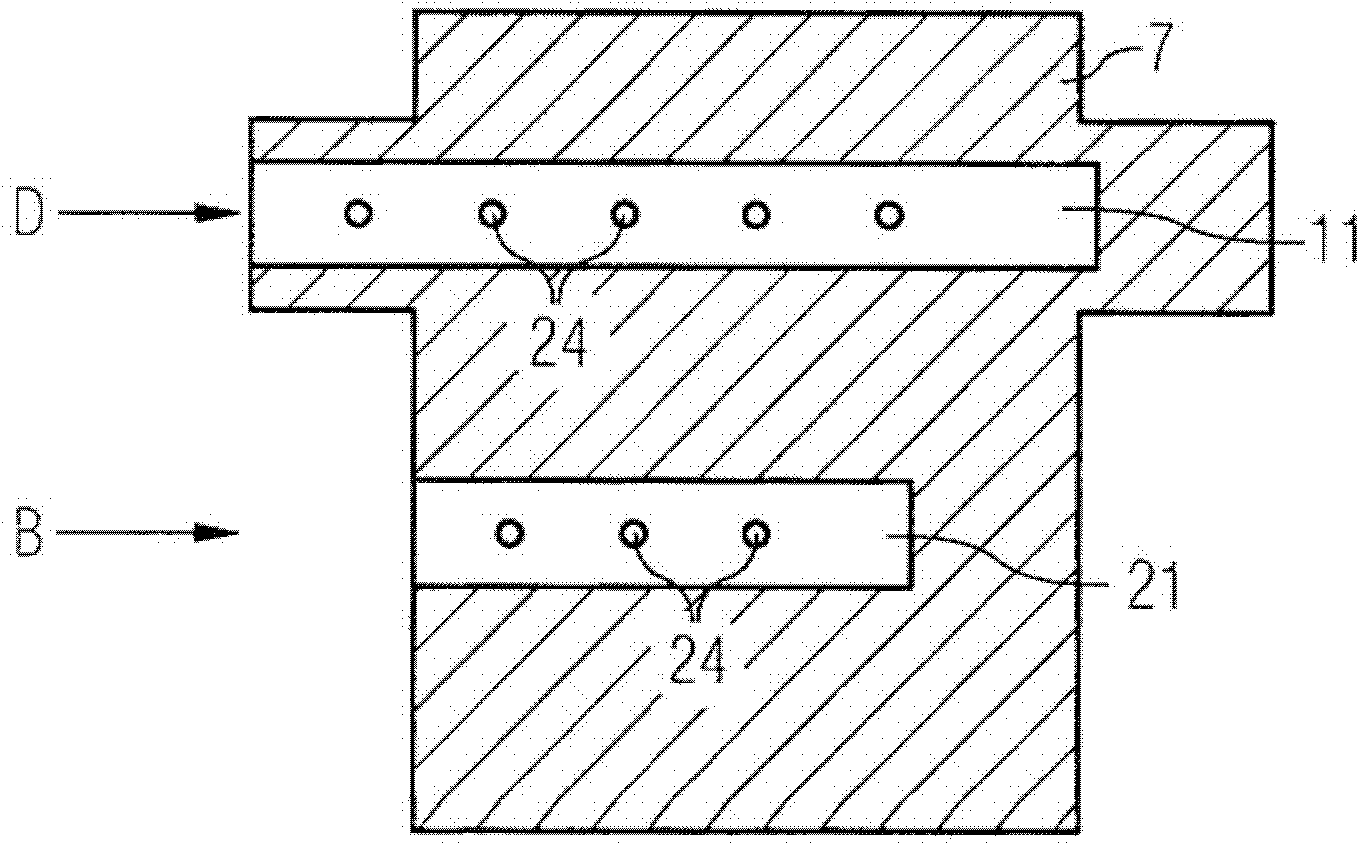

[0036] figure 1 It represents a burner arrangement 20 according to the prior art, which can be installed, for example, in the combustion chamber of a gas turbine arrangement, optionally in connection with a plurality of similar arrangements.

[0037] It consists of an inner section, the control burner system, and an outer section concentric with it and the main burner system. These two systems are suitable for operation with gaseous and / or liquid fuels in any combination. The control burner system consists of a central oil feed 1 (medium G) and an internal gas feed channel 2 (medium F) surrounding it concentrically. The control burner system is in turn surrounded by an inner air inlet channel 3 (medium E) arranged concentrically around the burner axis.

[0038] In or at the channel, a suitable ignition system can be provided, for which many design possibilities are known, so their description is omitted here. The central oil delivery device 1 has an oil injection nozzle 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com