Controlling method of delaying water leakage of pinch roll

A control method and pinch roll technology, applied in the field of hot rolling and finishing rolling, can solve problems such as the inability to accurately measure the shape of the tail of the strip, non-cutting of the tail by flying shears, and scrap steel accidents, so as to solve the external quality defects of steel coils and save The effect of using cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Segmented pressure control

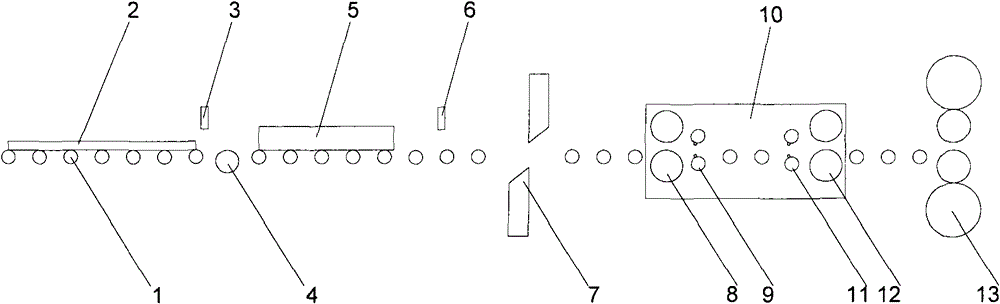

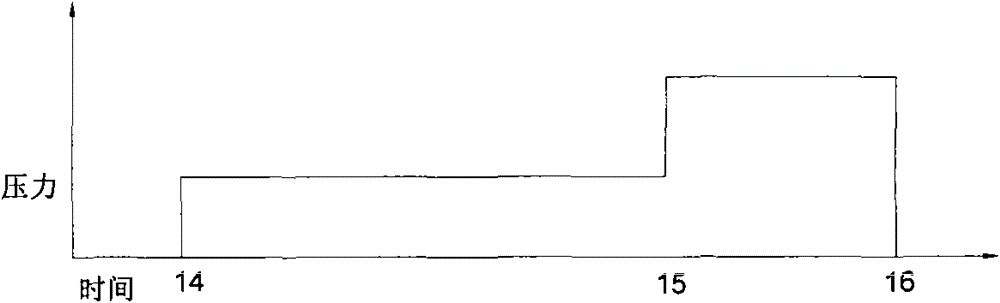

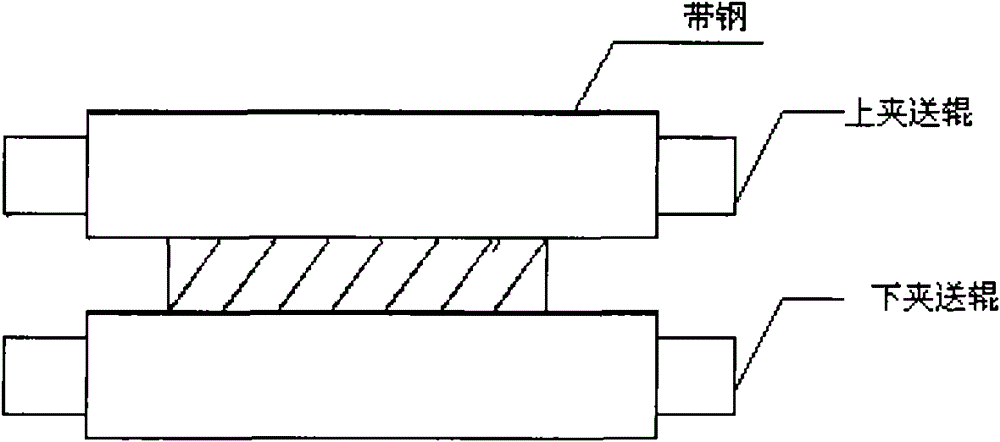

[0034] Please see attached figure 2 , when the head of the intermediate slab of the incoming rough rolling material reaches the flying shear area, the photocell before the flying shear is triggered and switched on, and the detected signal is sent to the BA basic automation, and the flying shear is carried out according to the measured shape of the head of the intermediate slab. cut head; see attached figure 2 , modify the constant pressure control of the pinch roller to two-stage pressure control: when the head of the intermediate billet reaches the pinch roller No. After the billet tail reaches the No. 1 photoelectric cell, the pinch roller is controlled by high pressure until the middle billet tail passes the No. 1 pinch roller; the purpose is to reduce the false detection problem caused by the pinch roller water leakage.

[0035] 2. Staging pressure control

[0036] During the period from the start of use of the new roller on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com