Method for preparing and constructing waterproof coating for steel structure roof

A technology of waterproof coating and waterproof coating film, applied in the field of materials, can solve the problems of expensive polyurea, difficult to cover the coil completely, poor flame retardant performance, etc., to reduce the risk of roof water leakage, improve roof water leakage, and achieve good construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] The implementation process of the method of the present invention will be described in detail below through the embodiments.

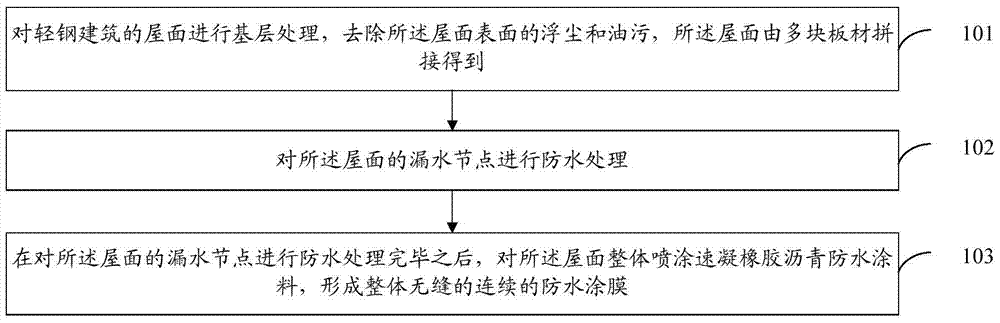

[0050] refer to figure 1 , which shows a flow chart of a method for preparing and constructing a waterproof coating for steel structure roofs according to an embodiment of the present invention, the method may specifically include:

[0051] Step 101: Perform basic treatment on the roof of the light steel building to remove floating dust and oil stains on the roof surface, and the roof is obtained by splicing a plurality of boards.

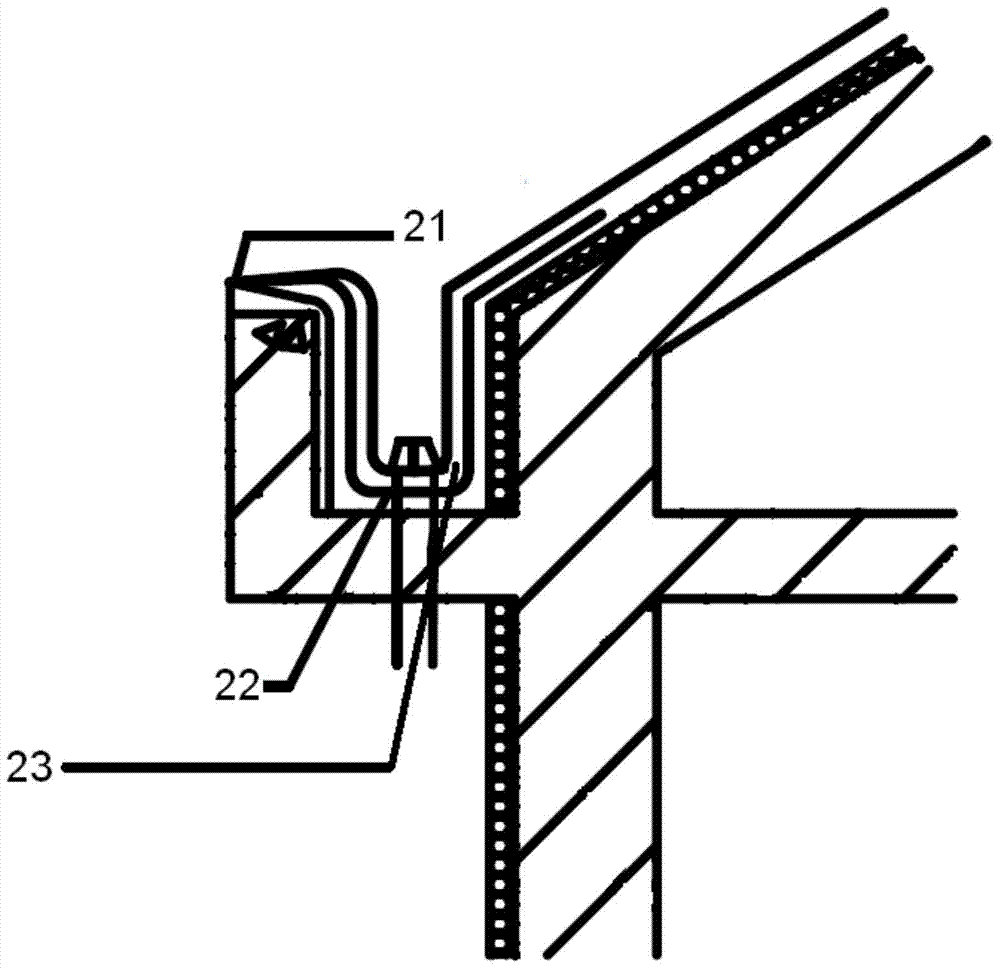

[0052] The roof of the light steel building is obtained by splicing a plurality of boards, and the boards include any one or more of single-layer boards, double-layer boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com