Flux-cored wire, preparation and application thereof

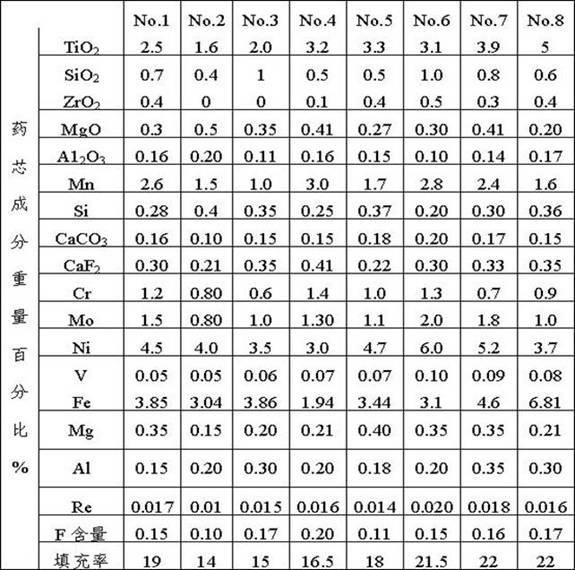

A technology of flux-cored welding wire and flux core, applied in welding equipment, welding medium, manufacturing tools, etc., to achieve good crack resistance and stable impact toughness at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

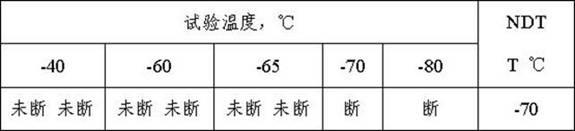

[0046] For the flux-cored welding wire of this embodiment, the composition of the flux core and its percentage content in the total mass of the flux-cored welding wire are as follows: TiO 2 , Mn, Si, SiO 2 , ZrO 2 , MgO, A1 2 o 3 , CaCO 3 , CaF 2 , Cr, Mo, Ni, V, Fe, Mg, Al.

[0047] The preparation method of the flux-cored welding wire in this embodiment: use the steel strip method to produce the flux-cored welding wire, O-shaped butt joint, fill the outer skin made of low-carbon steel strip with powder, the filling rate is 14~22%, and reduce the diameter after forming Finally, a finished welding wire with a diameter of 1.0~1.6mm is obtained.

[0048] The application of flux-cored wire in this embodiment: use argon-rich gas (Ar80%+CO 2 20%) under the protection of the flux-cored welding wire of the present invention at room temperature 25°C and relative humidity of 70%, the flux-cored welding wire of the present invention with a diameter of Φ1.2mm uses a current of 220...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com