Method for preparing hollow three-dimensional crimped polyphenylene sulfide staple fibers

A polyphenylene sulfide and three-dimensional crimping technology is applied in the preparation of hollow polyphenylene sulfide short fibers and the preparation of hollow three-dimensional crimped polyphenylene sulfide short fibers, and achieves the effects of superior performance, high hollow ratio and good operating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

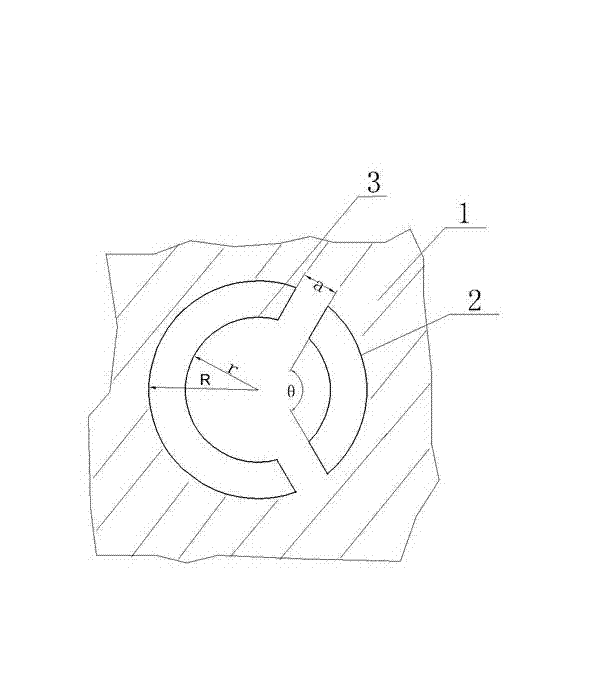

[0016] A method for preparing hollow three-dimensional crimped polyphenylene sulfide short fibers in this embodiment uses two components, wherein the first component uses linear polyphenylene sulfide with a melt index of 100g / 10min, and the second component uses Linear polyphenylene sulfide with a melt index of 120g / 10min; the two components are dried at 180°C for 8 hours and then passed through a twin-screw composite spinning device, and the temperature of each zone of the twin-screw composite spinning device is set at 280 ~320°C, after melting, it is sent into the spinning box by a metering pump, and melted and spun at a temperature of 325°C; figure 1 As shown, the spinneret hole of the spinneret 1 of the present invention is a ring formed by two concentric circles, and there are two gaps on the ring; the radius r of the inner ring 3 of the spinneret hole is 0.3mm, and the outer ring 2 The radius R is 0.8mm, and the notch spacing a is both 0.10mm, wherein the arc angle θ of ...

Embodiment 2

[0018] A method for preparing hollow three-dimensional crimped polyphenylene sulfide short fibers in this embodiment uses two components, wherein the first component uses linear polyphenylene sulfide with a melt index of 100g / 10min, and the second component uses Linear polyphenylene sulfide with a melt index of 150g / 10min; the two components are dried at 180°C for 8 hours and then passed through a twin-screw composite spinning device, and the temperature of each zone of the twin-screw composite spinning device is set at 280 ~320°C, after melting, it is sent into the spinning box by a metering pump, and melted and spun at a temperature of 325°C; figure 1 As shown, the spinneret hole of the spinneret 1 of the present invention is a ring formed by two concentric circles, and there are two gaps on the ring; the radius r of the inner ring 3 of the spinneret hole is 0.3mm, and the outer ring 2 The radius R is 0.8mm, and the notch spacing a is both 0.10mm, wherein the arc angle θ of ...

Embodiment 3

[0020] The preparation method of a hollow three-dimensional crimped polyphenylene sulfide short fiber in this embodiment adopts two kinds of components, wherein the first component adopts linear polyphenylene sulfide with a melt index of 50 g / 10min, and the second component adopts Linear polyphenylene sulfide with a melt index of 60g / 10min; the two components are dried at 180°C for 8 hours and then passed through a twin-screw composite spinning device, and the temperature of each zone of the twin-screw composite spinning device is set at 280 ~320°C, after melting, it is sent into the spinning box by a metering pump, and melted and spun at a temperature of 325°C; figure 1 As shown, the spinneret hole of the spinneret 1 of the present invention is a ring formed by two concentric circles, and there are two gaps on the ring; the radius r of the inner ring 3 of the spinneret hole is 0.3mm, and the outer ring 2 The radius R is 0.8mm, and the notch distance a is both 0.10mm, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com