LED lamp manufacturing method

A technology of LED lamps and manufacturing methods, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc., and can solve the problems of poor heat dissipation effect of LED light source parts, low production efficiency, and many heat-conducting layers of lamps. To facilitate the operation of automated equipment, reduce the use of materials, and solve the effect of light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

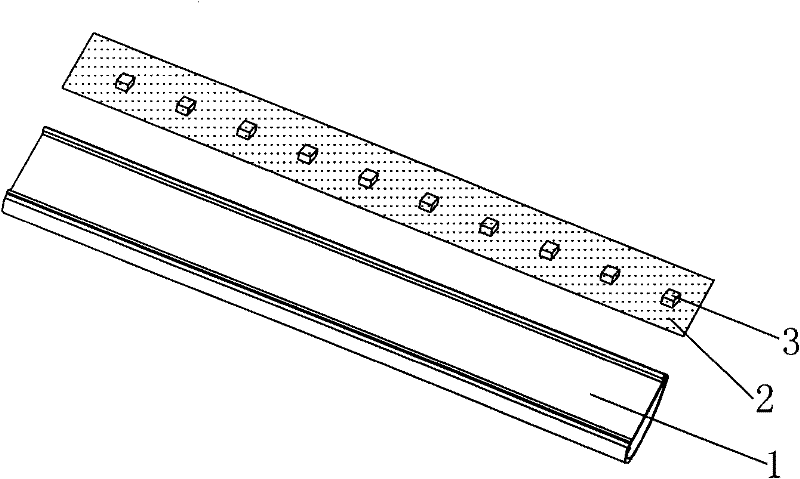

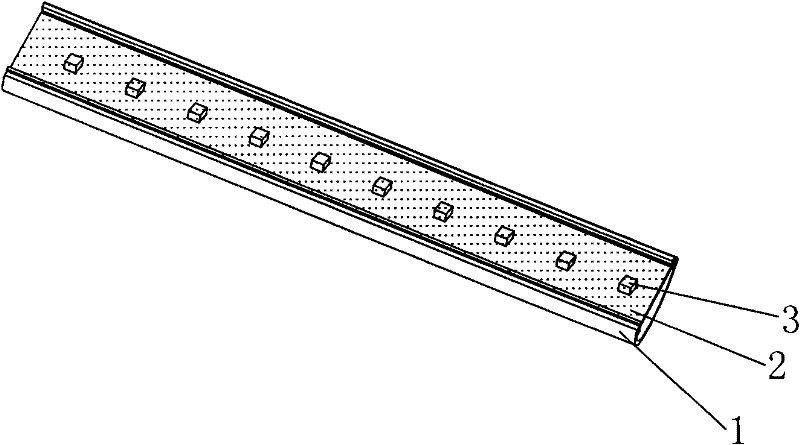

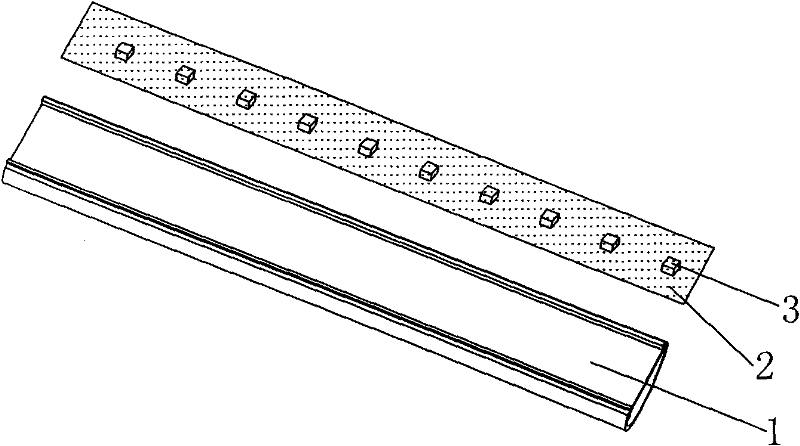

[0021] as attached figure 1 As shown, the LED lamp in this embodiment is mainly composed of a heat dissipation housing 1 , an LED chip 2 and a flexible circuit board 3 . Wherein, the heat dissipation casing 1 can be a copper casing, an aluminum casing, a magnesium-aluminum casing, a ceramic casing, or a magnesium-copper casing, and wires electrically connected to external circuits are arranged on the flexible circuit board 3 .

[0022] In this embodiment, in order to realize that the lamp has the advantages of small thermal resistance, high production efficiency, and low cost, the lamp is produced by the following method:

[0023] a. Pre-attach a layer of heat-conducting medium to the position where the LED chip needs to be installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com