Novel holographic optical tweezers system based on Talbot effect

A new type of holographic technology, applied in the field of laser holographic optical tweezers, can solve the problems of high requirements for operating skills, complex optical trap moving systems, and increase in the cost of holographic optical tweezers systems, and achieve industrialization, cost reduction, and compact and stable systems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

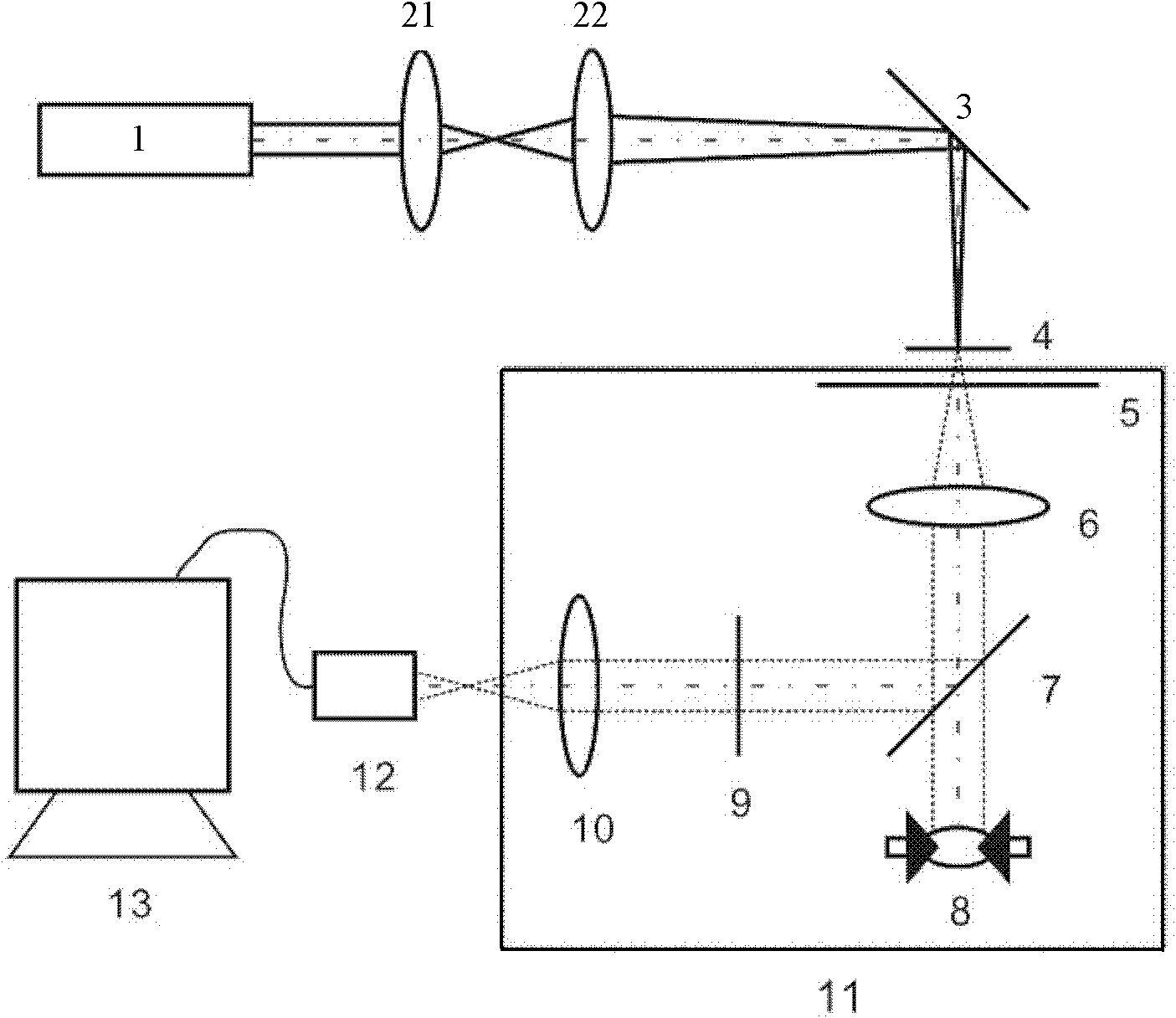

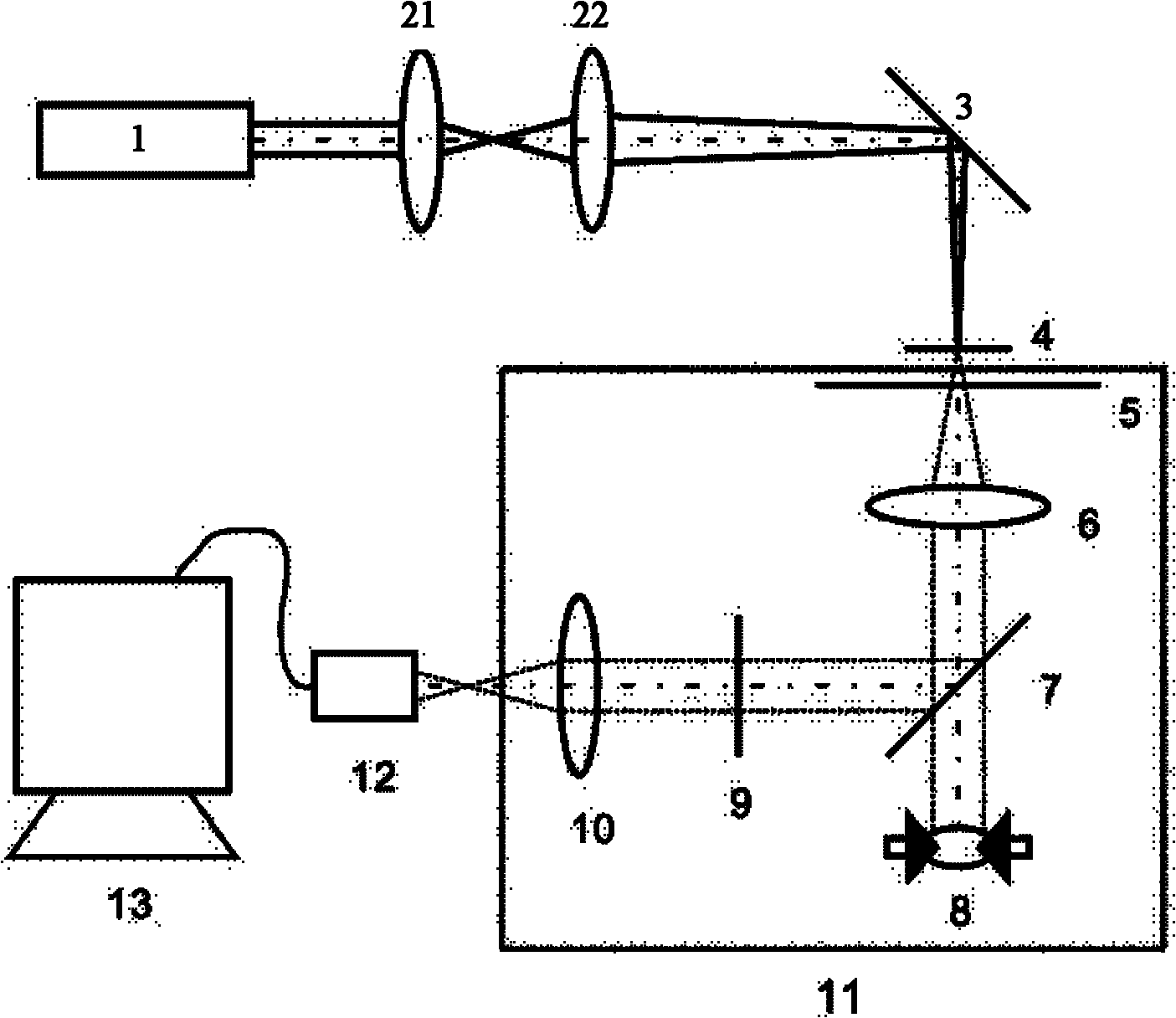

[0014] Such as figure 1 As shown, the embodiment of the present invention is provided with a laser 1, a first lens 21, a second lens 22, a mirror 3, a holographic element 4, an inverted microscope 11, a CCD image sensor 12 and a computer 13; the first lens and the second lens are sequentially The front and back are arranged between the laser beam output end of the laser 1 and the reflector 3, the laser 1, the first lens 21 and the second lens 22 are on the same optical axis, the laser light emitted by the laser 1 passes through the first lens and the second lens, and the first lens The focal point coincides with the initial position of the second lens, and the position of the laser beam focus point is controlled by fine-tuning the distance between the first lens and the second lens, so that the laser beam focus point falls on the holographic element 4; the particles are placed on the inverted microscope On the stage 5 of 11, by adjusting the distance between the stage 5 of the...

Embodiment 2

[0019] Same as Embodiment 1, the difference is that the holographic element 4 is realized by a spatial light modulator, the spatial light modulator is connected to the computer 13, the signal for calculating the hologram is generated by the computer, and the spatial light modulator is controlled by the computer, thereby Change the self-imaging light field distribution of the spatial light modulator, and then manipulate the motion of the particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com